Refurbishing Skate Wheels

Flat spots, egg shapes, and coning can all be from wheels easily provided you have the correct tools. Basically this is a one time investment that will pay back over your life.

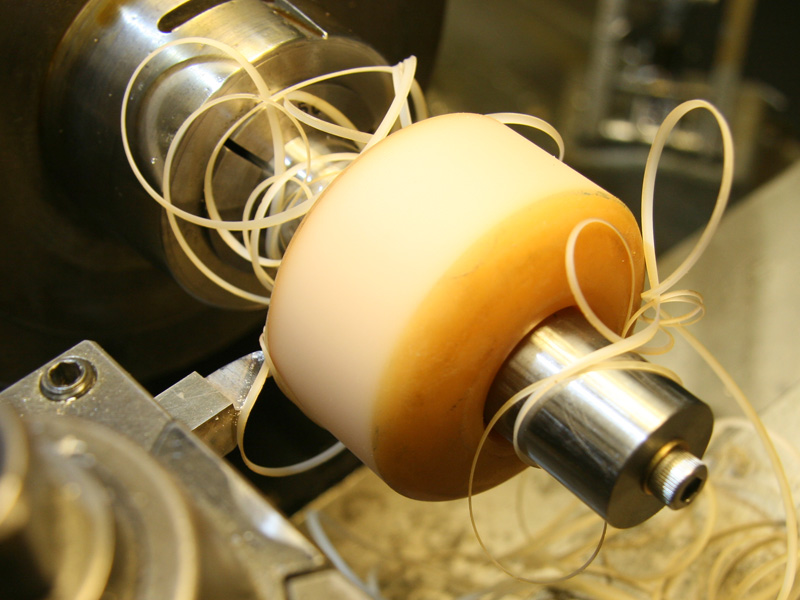

To turn a new surface on a set of used (or new) skate wheels, you will need access to a lathe and a special mandrel to hold each wheel.

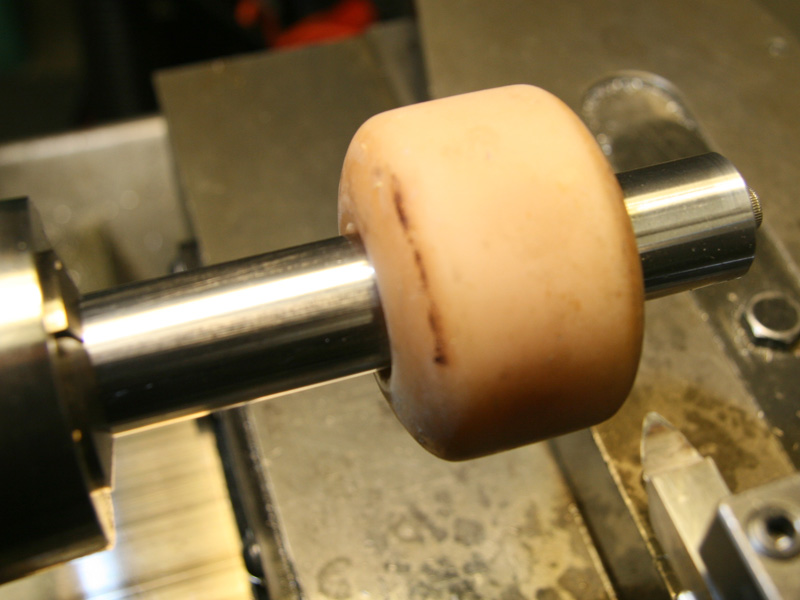

The Mandrel

This mandrel was made using some TP&G 22mm shaft (same size as 608 bearing OD) that I had laying around. I also ordered a 22mm collet to hold the mandrel for maximum precision.

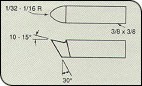

The Cutting Bit

A specially shaped bit must be used to cut urathane properly. It will have a very positive rake and deep chip breaker on the top, almost a knife edge.A turning surface speed of around 375 Ft./Min has been suggested.

TURNING & FACING

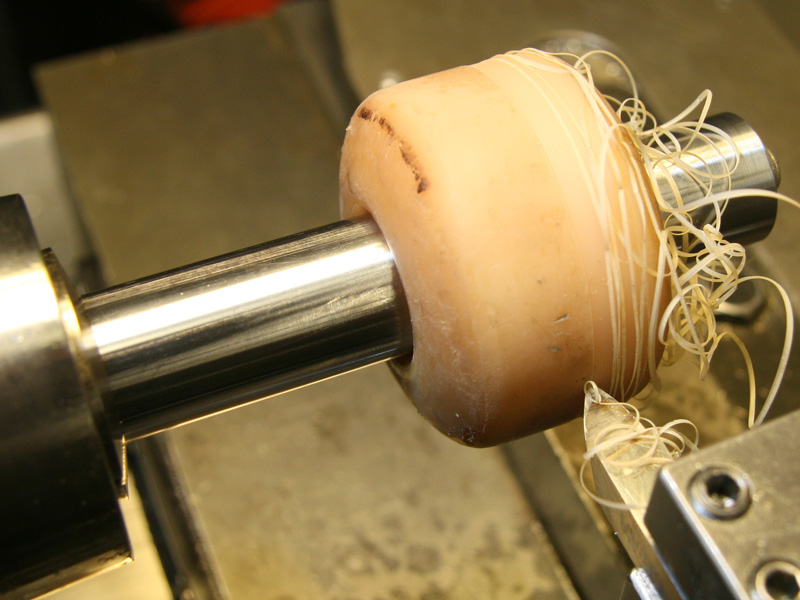

Tool clearances must be greater than those used for metal. The goal is to have little or no resistance as the tool travels through the urethane. The chip (material that is being cut away) should come off as a continuous strip or ribbon. A smooth surface on the top of your tool with aid in chip removal. This is very important to prevent the chip from wrapping back around the work piece. Good chip removal is also critical for heat removal and tool life.

In general, use sharp tools, high turning speed, and slow to moderate feeds (depending on hardness). Cutting tools for urethane must have sharp, carefully honed cutting edges. Sharpen tools on a honing stone for a razor sharp edge on the sides, tip, and top of your tools. We have found success with both high speed and carbide tools.

www.gallaghercorp.com

Freezing the wheels may make it easier to produce a nice finish in some cases.

Safety

DO NOT inhale the smoke or grinding dust from urethane or any elastomer or plastic. It is toxic.

Getting it done

Important: To keep consistant wheel diameters, start with the smallest wheel in the set. This will ensure that all wheels end up the same size.

Mount everything solid in the lathe. Use a collet if possible. My cutting bit was ground knife sharp and made of High Speed Steel. The edge was honed to perfection. It cut like going through warm butter.

I span the spindle fairly slowly, around 200rpm. The feed rate should be fast enough to just produce grooves. Attempting to elliminate the grooves may require freezing or lube. Without those measures, I was not able to produce a quality finish without grooves.

Wach out for string chips. They can cause havoc.

The final product. Not like new, but a lot of life left. Go nuts.

External Links

Gallagher Corporation - General Machining

Gallagher Corporation - Turning