Difference between revisions of "Hole Saws and Arbors"

(→Arbors) |

(→Consumable Hole Saws) |

||

| Line 5: | Line 5: | ||

Most [http://catalog.starrett.com/catalog/catalog/groups.asp?GroupID=199 general use] hole saws have a variable pitch. The [http://catalog.starrett.com/catalog/catalog/groups.asp?GroupID=358 sheet metal] saws will have a finer straight pitch. These sheet metal hole saws are the ones to use for thin bicycle tubing. They may not be available over the counter and may require an order to MSC or Grainger. | Most [http://catalog.starrett.com/catalog/catalog/groups.asp?GroupID=199 general use] hole saws have a variable pitch. The [http://catalog.starrett.com/catalog/catalog/groups.asp?GroupID=358 sheet metal] saws will have a finer straight pitch. These sheet metal hole saws are the ones to use for thin bicycle tubing. They may not be available over the counter and may require an order to MSC or Grainger. | ||

| + | |||

| + | Constant pitch left, variable pitch right.<br> | ||

| + | [[Image:Hole-saw-1.jpg]]<br> | ||

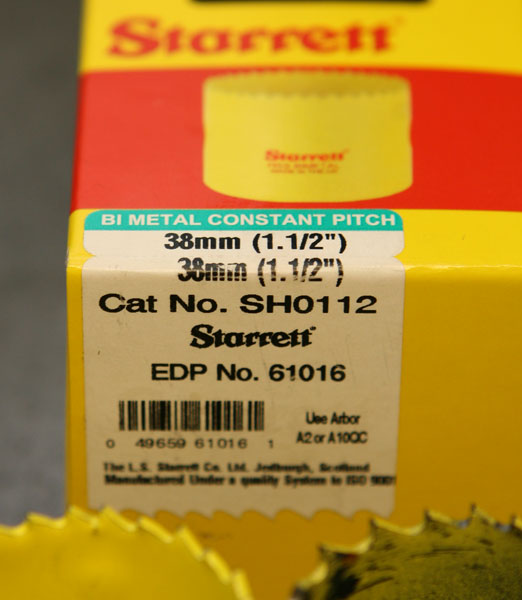

| + | The package of a Starrett constant pitch 1.500" saw. | ||

| + | [[Image:Hole-saw-2.jpg]]<br> | ||

===Facing the hole Saw=== | ===Facing the hole Saw=== | ||

Revision as of 14:43, 6 July 2007

Contents

Consumable Hole Saws

Most general use hole saws have a variable pitch. The sheet metal saws will have a finer straight pitch. These sheet metal hole saws are the ones to use for thin bicycle tubing. They may not be available over the counter and may require an order to MSC or Grainger.

Constant pitch left, variable pitch right.

The package of a Starrett constant pitch 1.500" saw.

Facing the hole Saw

The paint must be removed from the back of the hole saw so that it meets the arbor as square as possible.

A light lapping shows that this saw would have been prone to a slight wobble.

Sharpenable Hole Saws

Several types of sharpenable hole saws exist. some have carbide tips. Others are made of thick tool steel.

Nova sells some of the tool steel types, made by Nortac

Arbors

Most hole saw manufacturers provide some way of holding the saw. This is usually done in a less than precise way.

The natrual solution is to take some precision shaft and thread the end for what ever hole saw size you need. This has the advantage of being able to make an extended arbor.

Here is one that I made years ago.

For improved precision and more ridgid foundation to your saws, use an arbor For threaded drill chucks. These are available from several suppliers, but one of the cheapest I found was Victor Machinery Exchange, Inc.

VME threaded drill chuck arbor:

DCA-1/2-1220 1/2" Straight to 1/2"-20 Drill Chuck Arbor $5.90

The BIG PROBLEM! Hole Saws are threaded for 5/8"-18 not 5/8"-16 as is commonly available for drills.

Then we look at threaded shanks for mounting boring bar heads.

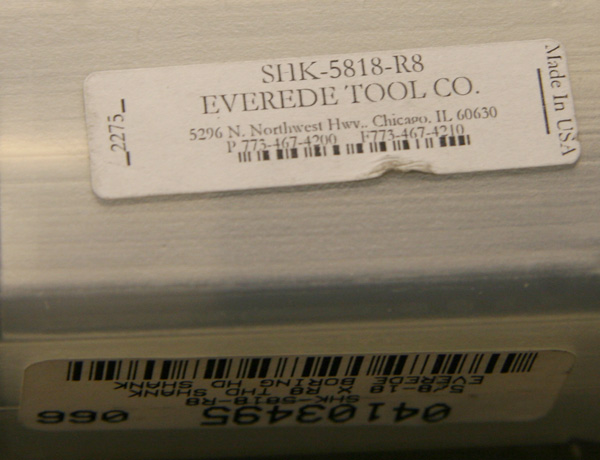

Index of 5/8-18 Threaded Shanks by Everede available from MSC Shank Mfr's P/N MSC P/N Price 1/2" Straight Shank SHK-5818-500 04103453 $45.75 5/8" Straight Shank SHK-5818-625 04103461 $45.75 3/4" Straight Shank SHK-5818-750 04103479 $45.75 1" Straight Shank SHK-5818-1000 04103487 $45.75 R8 Shank SHK-5818-R8 04103495 $45.75

Another source of shanks is Sev Cal Tooling

The Face of the tool was crummy looking.

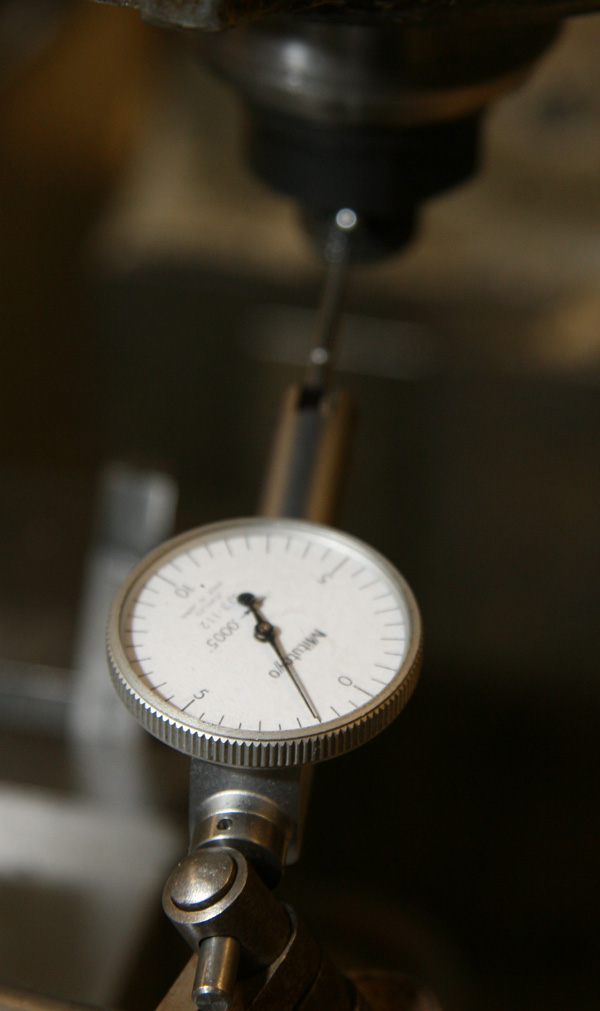

I indicated the face as 0.0015" out.

Set the mill up as a lathe to face the end.

Much better!

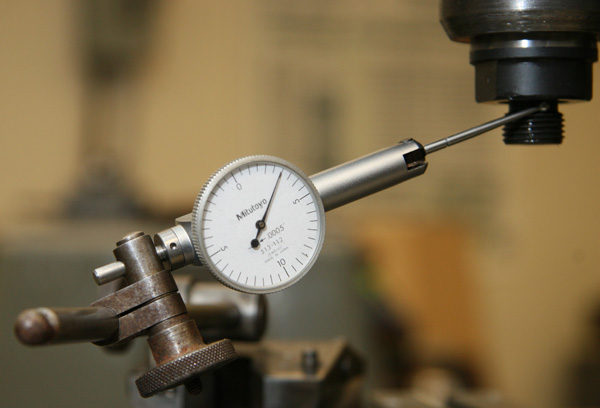

The threads off center by as much as 0.0030". This may not be true. It was hard to indicate.

Personally, I prefer to use either a R8 or 5C tool whenever I can. They are the most ridged and accurate way of mounting a tool.

Also, for an extended R8 mounting a 5/8-18 thread saw, you can cut an R8 blank from Allied Machine. At $156 for the smallest model, this is not an option at this point. Plus, you would need a 24mm collet to hold the R8 in a lathe.

If you mitre on a lathe and need a 5C chuck arbor, a 5C Plug Chuck with 1-3/4" Extended Nose Length and no pilot hole should be ordered. It can be threaded for what ever saw you need. Available from Hardinge, P/N 10150000000000, $30.25.

Truing Hole Saws

Hole saws may not end up perfectly round. A frame builder may have to true the saw by spinning it on a lathe and cutting material from behind the tips that extend past the cut area.