Difference between revisions of "Aluminum Radiator Repair"

From Pvdwiki

(→Cleaning the Solder Area) |

(→Cleaning the Solder Area) |

||

| Line 23: | Line 23: | ||

===Cleaning the Solder Area=== | ===Cleaning the Solder Area=== | ||

| − | Paint stripper, a soft brush, water, and compressed air clean the area fine. | + | Paint stripper, a soft brush, water, and compressed air clean the area fine.<br> |

[[Image:Paint-stripper.jpg]] | [[Image:Paint-stripper.jpg]] | ||

| − | It foams as it works. | + | It foams as it works.<br> |

[[Image:Paint-stripper-working.jpg]] | [[Image:Paint-stripper-working.jpg]] | ||

Revision as of 00:41, 31 July 2007

Tig Welding

The solder did not work for this repair. Nothing seemed to get the solder to stick to the radiator. In the end, I TIG welded the hole. It was tough. I used a 1/16" electrode at 40 amps and 3/32 filler wire. I would have loved a smaller electrode and wire, but this stuff is small as it is.

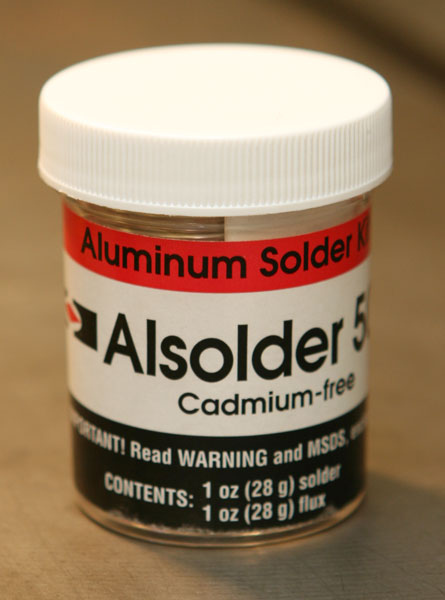

The Solder

Aluminum solder exists. I could not get it to work.

ALSOLDER 500, PDS-Flow at 482°F.

Stay-Clean Aluminum Flux, PDS- A honey like liquid flux.

Kit Price - $27.37 from Praxair.

The Torch

Mapp gas (C3H4) produces a flame temperature of 5301° F (2927° C)

Propane gas (C3H8) produces a flame temperature of 4325° F (2385°C)

Cleaning the Solder Area

Paint stripper, a soft brush, water, and compressed air clean the area fine.

It foams as it works.