Shimming Eccentric Bottom Brackets

Recently, I put together a 17" 2006 Zion 660EBB Singlespeed frame.

It has an eccentric bottom bracket with dual locking set screws.

The Problem

One huge problem with this system is that the eccentric doesn't even come close to fitting the shell snug. It has room to rock around like they were two unsuited parts. This will lead to problems in the future if not soon.

The shell measures 2.141" to 2.150" (slightly distorted due to welding) The eccentric measures 2.126"

By having a well greased snug fit, the bottom bracket will have much less room to rock around and creek. Also, it will require much less clamping force with the screws to keep it in place. This is nice for long term service, as well as keeping the eccentric from spinning when hitting rocks.

Reaming the Shell Round

For the best possible fit, I will be reaming the bottom bracket shell round.

I will use an adjustable hand reamer (MSC # 02239135) Industrial size M. This will eliminate the distorted shape and make the shell easier to shim.

Shiming the Eccentric

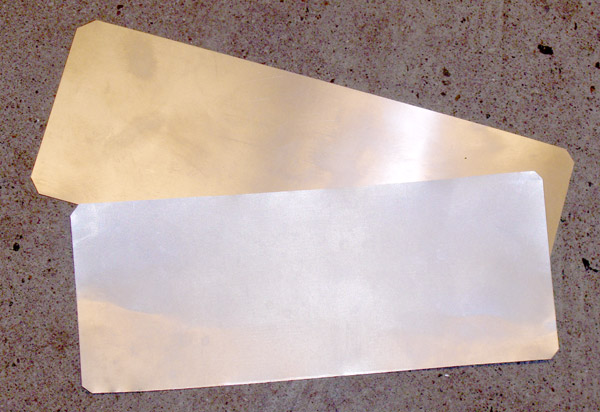

I will fill the gap using some stainess steel shim stock. At this point, I have to cut some 0.0075" and some 0.010" stock to find out what works best.

A 0.010" shim and a 0.0015" shim. Together they will take up 0.023" of diameter, bringing the eccentric to 2.149".

Greasing and Installing

Marine Grease