Refurbishing Skate Wheels

To turn a new surface on a set of used (or new) skate wheels, you will need access to a lathe and a special mandrel to hold each wheel.

This mandrel was made using some 22mm shaft (same size as 608 bearing OD) that I had laying around. I also ordered a 22mm collet to hold the mandrel for maximum precision.

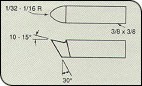

A specially shaped bit must be used to cut urathane properly. It will have a very positive rake and deep chip breaker on the top, almost a knife edge.A turning surface speed of around 375 Ft./Min has been suggested.

TURNING & FACING

Tool clearances must be greater than those used for metal. The goal is to have little or no resistance as the tool travels through the urethane. The chip (material that is being cut away) should come off as a continuous strip or ribbon. A smooth surface on the top of your tool with aid in chip removal. This is very important to prevent the chip from wrapping back around the work piece. Good chip removal is also critical for heat removal and tool life. www.gallaghercorp.com

In general, use sharp tools, high turning speed, and slow to moderate feeds (depending on hardness). Cutting tools for urethane must have sharp, carefully honed cutting edges. Sharpen tools on a honing stone for a razor sharp edge on the sides, tip, and top of your tools. We have found success with both high speed and carbide tools.

Freezing the wheels may make it easier to produce a nice finish in some cases.

DO NOT inhale the smoke or grinding dust from urethane or any elastomer or plastic. It is toxic.

External Links

Gallagher Corporation - General Machining

Gallagher Corporation - Turning