Difference between revisions of "Shimming Eccentric Bottom Brackets"

(→Greasing and Installing) |

(→The Standard) |

||

| (17 intermediate revisions by 3 users not shown) | |||

| Line 4: | Line 4: | ||

===The Problem=== | ===The Problem=== | ||

| − | + | One huge problem with this system is that the eccentric doesn't even come close to fitting the shell snug. It has room to rock around like they were two unsuited parts. Which in fact they are. | |

| − | The shell measures 2.141" to 2.150" (slightly distorted due to welding) - Obviously a shell for a Phil Wood eccentric<br> | + | The shell measures 2.141" to 2.150" (54.5mm)(slightly distorted due to welding) - Obviously a shell for a Phil Wood eccentric<br> |

| − | The eccentric measures 2.126" (54mm) - Obviously an eccentric for a generic shell. | + | The eccentric measures 2.126" (54mm) - Obviously an eccentric for a generic shell. |

| − | Why would they do this? Simple, I love the Tawanese | + | Cam - 2.126" (54mm)<br> |

| + | Shell - 2.146" (54.5mm)<br> | ||

| + | Shell OD- 2.375" (60.3mm)<br> | ||

| + | Shell Width - 2.677" (68mm)<br> | ||

| + | Lock Screw Spacing - 1.417" (36mm)<br> | ||

| + | |||

| + | Why would they do this? Simple, I love the Tawanese, A large shell will accomodate either solid eccentric without the need for expensive machining or finish work. Is this the best way to do it? Not at all, but it is profitable and that is what is most important to them. | ||

This will lead to problems in the future if not soon. | This will lead to problems in the future if not soon. | ||

| Line 15: | Line 21: | ||

<br><br>[[Image:Bbshim3.jpg]]<br> | <br><br>[[Image:Bbshim3.jpg]]<br> | ||

| − | By having a well greased | + | By having a well greased snug fit, the bottom bracket will have much less room to rock around and creek. Also, it will require much less clamping force with the screws to keep it in place. This is nice for long term service, as well as keeping the eccentric from spinning when hitting rocks. |

===The Standard=== | ===The Standard=== | ||

| Line 21: | Line 27: | ||

Generic sizes most comonly available measure generic 54mm (2.126"). | Generic sizes most comonly available measure generic 54mm (2.126"). | ||

| − | [http://www.bushnelltandems.com/eccentric.html Bushnell Eccentrics] (one of the finest made) is and expanding eccentric that is very light. It is also very expensive. It's initial diameter is 2.118" and is designed to expand from | + | [http://www.bushnelltandems.com/eccentric.html Bushnell Eccentrics] (one of the finest made) is and expanding eccentric that is very light. It is also very expensive. It's initial diameter is 2.118" and is designed to expand from 2.120" to 2.125". A very close margin to generic 54mm (2.126"). |

[http://www.philwood.com/Price%20List/P16.pdf Phil Wood] NFES814 Eccentric and NFBSE8 Shell are designed around a 2.142" size, althought custom versions of this are available. | [http://www.philwood.com/Price%20List/P16.pdf Phil Wood] NFES814 Eccentric and NFBSE8 Shell are designed around a 2.142" size, althought custom versions of this are available. | ||

| Line 30: | Line 36: | ||

===Reaming the Shell Round=== | ===Reaming the Shell Round=== | ||

| − | For the best possible fit, I will be reaming the bottom bracket shell round | + | For the best possible fit, I will be reaming the bottom bracket shell round. |

I will use an adjustable hand reamer (MSC # 02239135) Industrial size M. This will eliminate the distorted shape and make the shell easier to shim. | I will use an adjustable hand reamer (MSC # 02239135) Industrial size M. This will eliminate the distorted shape and make the shell easier to shim. | ||

| Line 44: | Line 50: | ||

The reamer requires the use of a cutting oil as well. Motor oil is fine in a pinch. | The reamer requires the use of a cutting oil as well. Motor oil is fine in a pinch. | ||

| − | After a light cutting pass, the distortion in the shell is obvious. | + | After a light cutting pass, the distortion in the shell is obvious. The shell shows that matirial was being removed from some parts of the shell and not at others. This shows where the shell is not in round. When finished, the reamer will 'just' cut the entire surface of the shell. |

<br>[[Image:Bbshim6.jpg]]<br> | <br>[[Image:Bbshim6.jpg]]<br> | ||

| Line 61: | Line 67: | ||

===Hardware Replacement=== | ===Hardware Replacement=== | ||

| − | The two round head cap screws were replaced with Stainless Steel Cap screws for use with a larger wrench and matirial to grab in a worst-case situation. Now a 5mm allen wrench can be used. | + | The two round head cap screws were replaced with Stainless Steel Cap screws for use with a larger wrench and matirial to grab in a worst-case situation. Now a 5mm allen wrench can be used.<br> |

| + | |||

| + | [[Image:Bbshim10.jpg]]<br><br> | ||

| + | The bolts will have a rough end. This needs to be smoothed out to prevent too much scarring to the cam. This scarring will make it hard to properly adjust the cam as time goes by.<br> | ||

| + | [[Image:Ebb-bolts.jpg]]<br><br> | ||

| + | Beltsand the ends to flatten them and champher the edge.<br> | ||

| − | + | [[Image:Ebb-bolts2.jpg]]<br><br> | |

===Greasing and Installing=== | ===Greasing and Installing=== | ||

| − | Marine Grease. Use marine grease | + | Marine Grease. Use marine grease. |

| − | Test fitting. | + | Test fitting. No grease yet. Grease up when you know it will go together right. |

<br>[[Image:Bbshim8.jpg]]<br> | <br>[[Image:Bbshim8.jpg]]<br> | ||

| Line 84: | Line 95: | ||

[[category:Bicycle]] | [[category:Bicycle]] | ||

[[category:Drivetrain (Bicycle)]] | [[category:Drivetrain (Bicycle)]] | ||

| + | [[category:Frame Building]] | ||

Latest revision as of 14:19, 18 July 2010

Recently, I put together a 17" 2006 Zion 660EBB Singlespeed frame.

It has an eccentric bottom bracket with dual locking set screws.

Contents

The Problem

One huge problem with this system is that the eccentric doesn't even come close to fitting the shell snug. It has room to rock around like they were two unsuited parts. Which in fact they are.

The shell measures 2.141" to 2.150" (54.5mm)(slightly distorted due to welding) - Obviously a shell for a Phil Wood eccentric

The eccentric measures 2.126" (54mm) - Obviously an eccentric for a generic shell.

Cam - 2.126" (54mm)

Shell - 2.146" (54.5mm)

Shell OD- 2.375" (60.3mm)

Shell Width - 2.677" (68mm)

Lock Screw Spacing - 1.417" (36mm)

Why would they do this? Simple, I love the Tawanese, A large shell will accomodate either solid eccentric without the need for expensive machining or finish work. Is this the best way to do it? Not at all, but it is profitable and that is what is most important to them.

This will lead to problems in the future if not soon.

By having a well greased snug fit, the bottom bracket will have much less room to rock around and creek. Also, it will require much less clamping force with the screws to keep it in place. This is nice for long term service, as well as keeping the eccentric from spinning when hitting rocks.

The Standard

Generic sizes most comonly available measure generic 54mm (2.126").

Bushnell Eccentrics (one of the finest made) is and expanding eccentric that is very light. It is also very expensive. It's initial diameter is 2.118" and is designed to expand from 2.120" to 2.125". A very close margin to generic 54mm (2.126").

Phil Wood NFES814 Eccentric and NFBSE8 Shell are designed around a 2.142" size, althought custom versions of this are available.

Easton Sports has another standard used in their shells. Their eccentric measures 2.155"

So the proper ream size of a tandem bottom bracket shell is in question. This would help explain the array of problems that people are having with these.

Reaming the Shell Round

For the best possible fit, I will be reaming the bottom bracket shell round.

I will use an adjustable hand reamer (MSC # 02239135) Industrial size M. This will eliminate the distorted shape and make the shell easier to shim.

The reamer is huge. OAL 410mm.

A 12 point socket helps drive the reamer. It may take about 50 rotations, so don't use a rickety setup.

The reamer requires the use of a cutting oil as well. Motor oil is fine in a pinch.

After a light cutting pass, the distortion in the shell is obvious. The shell shows that matirial was being removed from some parts of the shell and not at others. This shows where the shell is not in round. When finished, the reamer will 'just' cut the entire surface of the shell.

Shiming the Eccentric

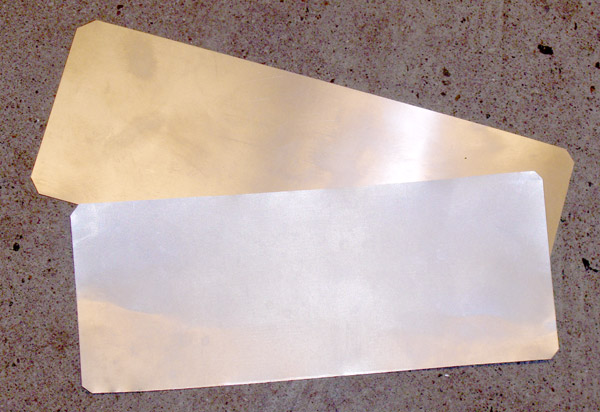

I will fill the gap using some stainess steel shim stock. It is best to use a single shim so that it is as thick as it can be for durability sake. I prefer stainless shims over brass for the same reason.

A 0.010" shim and a 0.0015" shim. In the end, just the 0.010" shim was used and it was a very snug fit.

The greased shim with a bend to help installation

Hardware Replacement

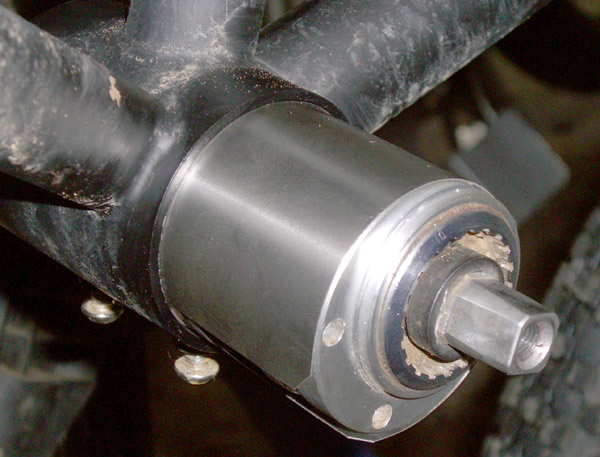

The two round head cap screws were replaced with Stainless Steel Cap screws for use with a larger wrench and matirial to grab in a worst-case situation. Now a 5mm allen wrench can be used.

The bolts will have a rough end. This needs to be smoothed out to prevent too much scarring to the cam. This scarring will make it hard to properly adjust the cam as time goes by.

Beltsand the ends to flatten them and champher the edge.

Greasing and Installing

Marine Grease. Use marine grease.

Test fitting. No grease yet. Grease up when you know it will go together right.

I also need to find a way to rust proof the edges.