Difference between revisions of "Special Fork Cap Sockets"

From Pvdwiki

| Line 12: | Line 12: | ||

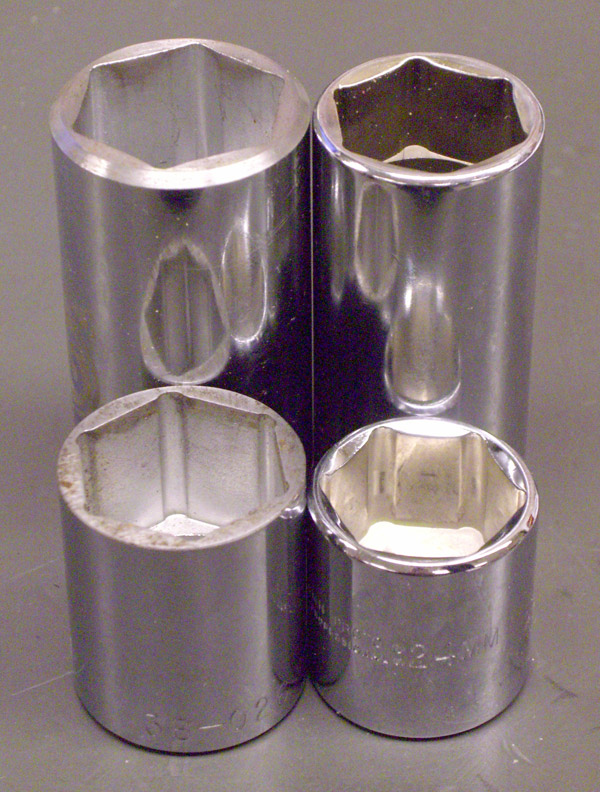

A standard 6 point socket. | A standard 6 point socket. | ||

| − | <br>[Image:Forkcaptool1.jpg]<br> | + | <br>[[Image:Forkcaptool1.jpg]]<br> |

This is what we are shooting for. | This is what we are shooting for. | ||

| − | <br>[Image:Forkcaptool2.jpg]<br> | + | <br>[[Image:Forkcaptool2.jpg]]<br> |

Turning it flat. | Turning it flat. | ||

| − | <br>[Image:Forkcaptool3.jpg]<br> | + | <br>[[Image:Forkcaptool3.jpg]]<br> |

A full set of 3 sizes. | A full set of 3 sizes. | ||

| − | <br>[Image:Forkcaptool4.jpg]<br> | + | <br>[[Image:Forkcaptool4.jpg]]<br> |

Revision as of 18:46, 29 November 2006

Fork caps on bicycle supsension forks are notoriously difficult to work with. They are usually a low profile with a hex and a very thin wall. Any damage to this cap will cause problems.

Common sockets and wrences will have champhers on the ends that often exceed the hight available to lever against. This champher needs to be removed.

The trick for doing it right is to machine or grind a 6 point socket flat. A lathe works best, but a belt sander will do the trick.

24mm - Rock Shocks 32mm Forks. 26mm - Fox 32mm Forks. 32mm - Fox 36mm Forks.

Any cheap socket will work for this. I like to get Proto sockets from MSC. Great product for the lowest price.