Difference between revisions of "Stem Preparation"

(→How) |

|||

| (2 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

===Why=== | ===Why=== | ||

| − | Threadless headset systems require a nice sqare face to push against for proper function. | + | Threadless headset systems require a nice sqare face to push against for proper function. This is important for well engineered systems that use the Dia-Compe patent, but absolutely critical if using a poorly designed Chris King headset. |

| − | ===How===A simple madrel is made to fit a 1" collet and the 1.125" stem. I prefre to do all work with a collet if I can.<br> | + | Rarely is a cast or fabricated stem faced with any usable precision. The price point just doesn't justify it. You must do this yourself. Machined stems rarely require this treatement. |

| + | |||

| + | ===How=== | ||

| + | A simple madrel is made to fit a 1" collet and the 1.125" stem. Steel is a good material since when spinning on the lathe the stem will create an unbalanced load. | ||

| + | |||

| + | I prefre to do all work with a collet if I can. I prefer the speed of set-up and the precision.<br> | ||

[[Image:Stem face 1.jpg]]<br><br> | [[Image:Stem face 1.jpg]]<br><br> | ||

[[Image:Stem face 2.jpg]]<br><br> | [[Image:Stem face 2.jpg]]<br><br> | ||

Latest revision as of 02:11, 5 May 2007

Why

Threadless headset systems require a nice sqare face to push against for proper function. This is important for well engineered systems that use the Dia-Compe patent, but absolutely critical if using a poorly designed Chris King headset.

Rarely is a cast or fabricated stem faced with any usable precision. The price point just doesn't justify it. You must do this yourself. Machined stems rarely require this treatement.

How

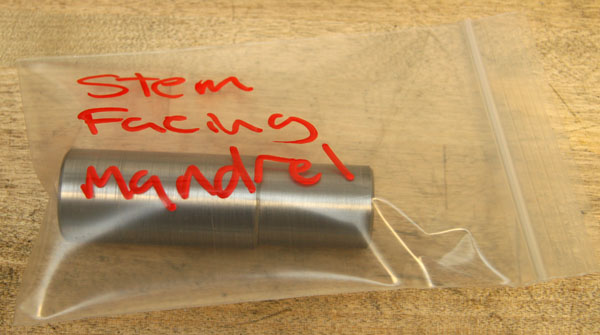

A simple madrel is made to fit a 1" collet and the 1.125" stem. Steel is a good material since when spinning on the lathe the stem will create an unbalanced load.

I prefre to do all work with a collet if I can. I prefer the speed of set-up and the precision.

Very carefully spin the stem on the lathe. Take as little metal off as needed to get a nice face.

Always bag and lable specially made tools. Years later the tool will be clean, in good shape, and clearly marked.