This is a post long overdue.

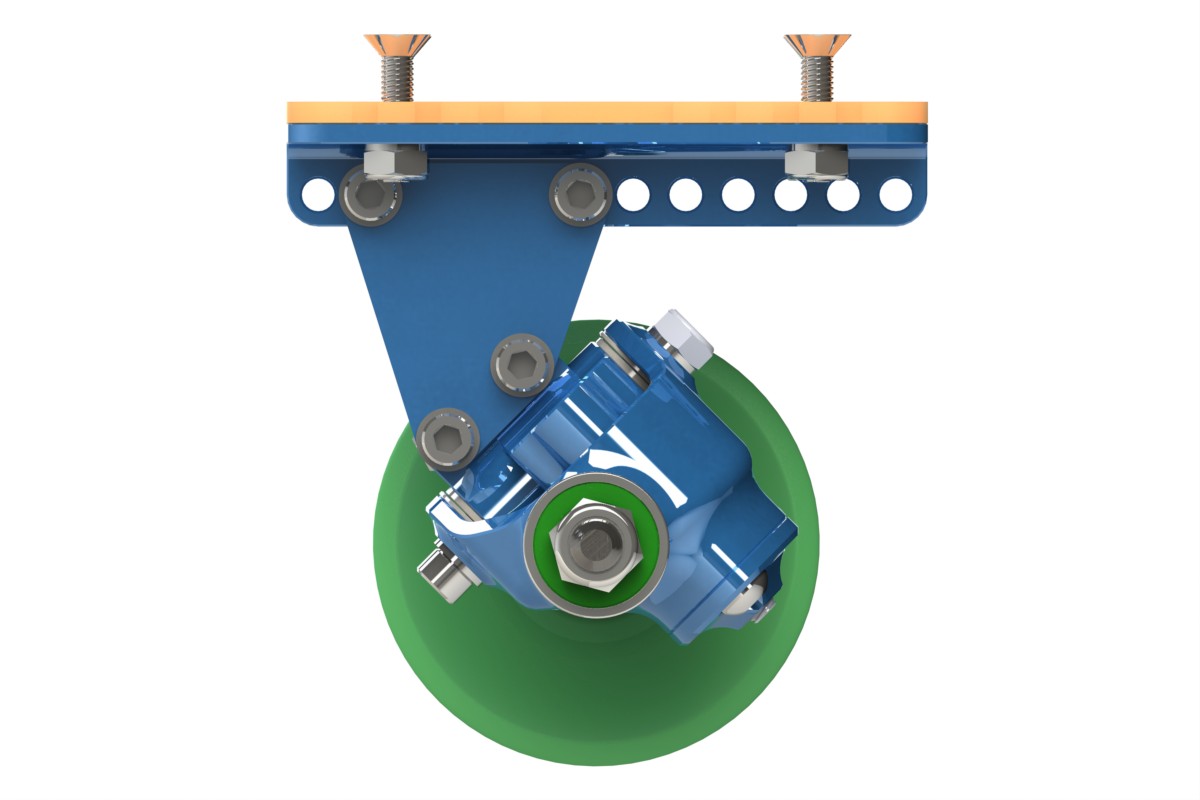

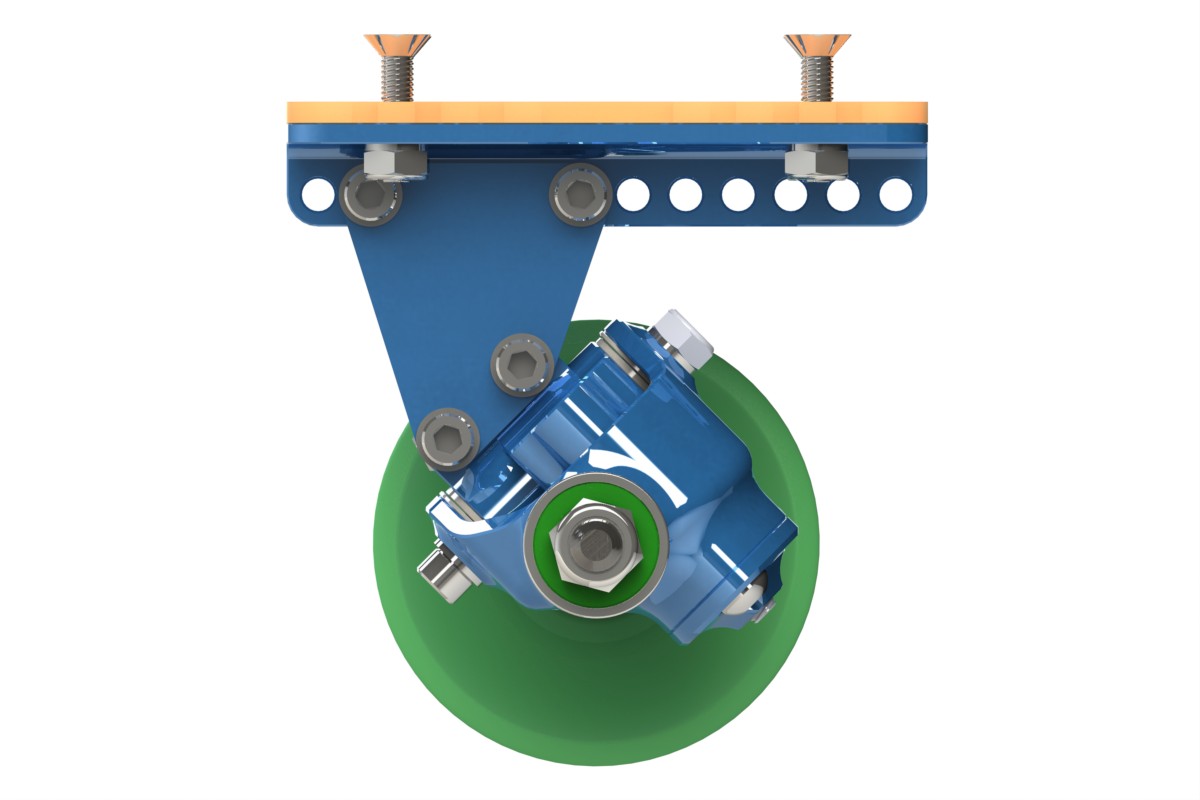

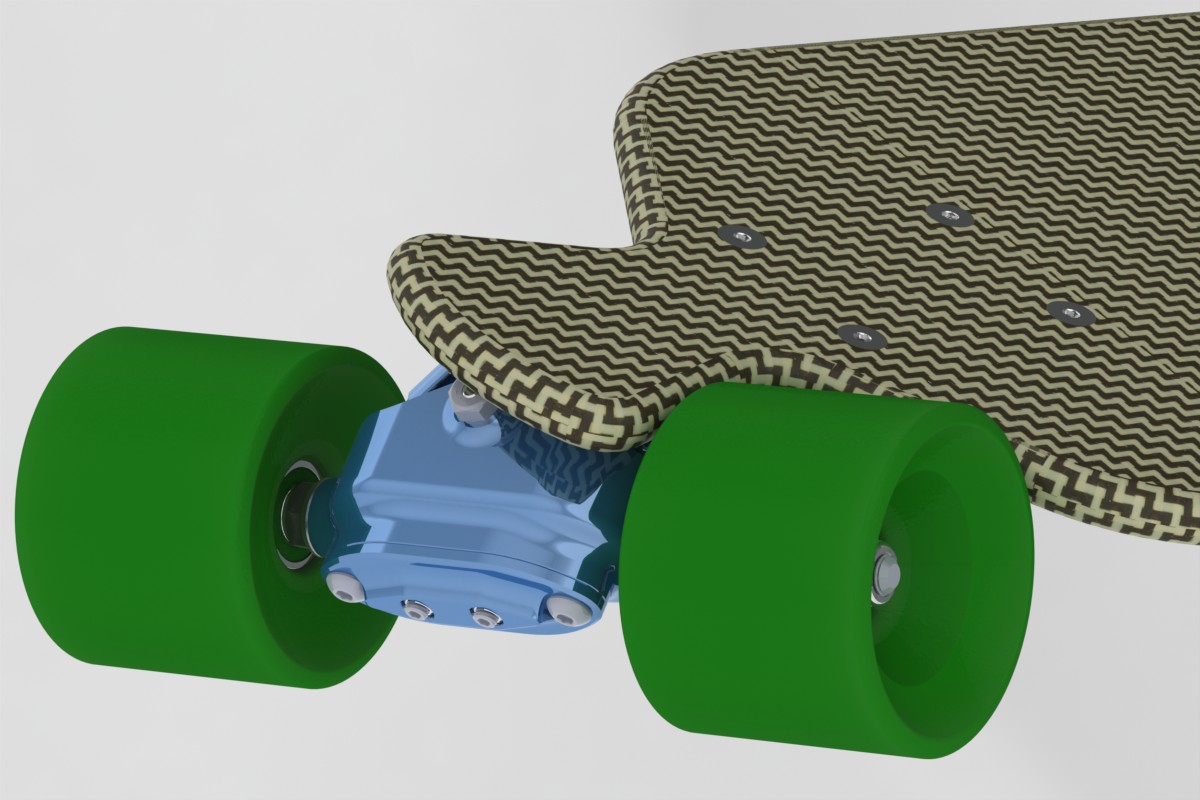

A side view of the truck. Showing the additional ground clearance in the final version.

Way back in 2001, I was in San Francisco and Oakland visiting for a west coast marriage reception for my new wife and I (a long since dissolved affair). I had needed to move back to Massachusetts to pick up the pieces of the family business after my father retired forcing me there even though my life was in the Bay Area.

While with an old friend, Gary Mathis, we ventured over to Comet Skateboards where some pretty stunning wood and fiber were being formed into skate decks. Comet specialized in longboard and slalom racing decks as well as contract work for flipper start-ups. Chris Sullivan (another friend) was working getting the CNC router online and production smoothed out. The setup was very impressive.

Gary and I found ourselves with some time to kill as the shop was still going hard in production early in the afternoon. We borrowed a couple slalom boards to play with in the streets outside to kill some time. Give a skater a board and time will be killed. Ha.

I was utterly discusted with the state of affairs in skateboarding racing hardware. While these guys were busting balls to make amazing decks and others were molding super urethanes and wheel shapes, trucks were stone age. Ancient Independent castings were held precariously in position above stacks of nuts and washers to get them to turn. Funky bushings were sliced and smashed into place that looked like junk shop parts more than race parts. I had spent years in various forms of racing and high tech production and this stuff was barely recognizable to me as performance hardware.

That discust planted a seed in me. Nobody was making anything really close to race trucks in skateboarding. The ones that said they did obviously had no idea how a truck worked or how to do good engineering. It was a cruel joke really. It took a few months but I started on making something better. Soon I had some results.

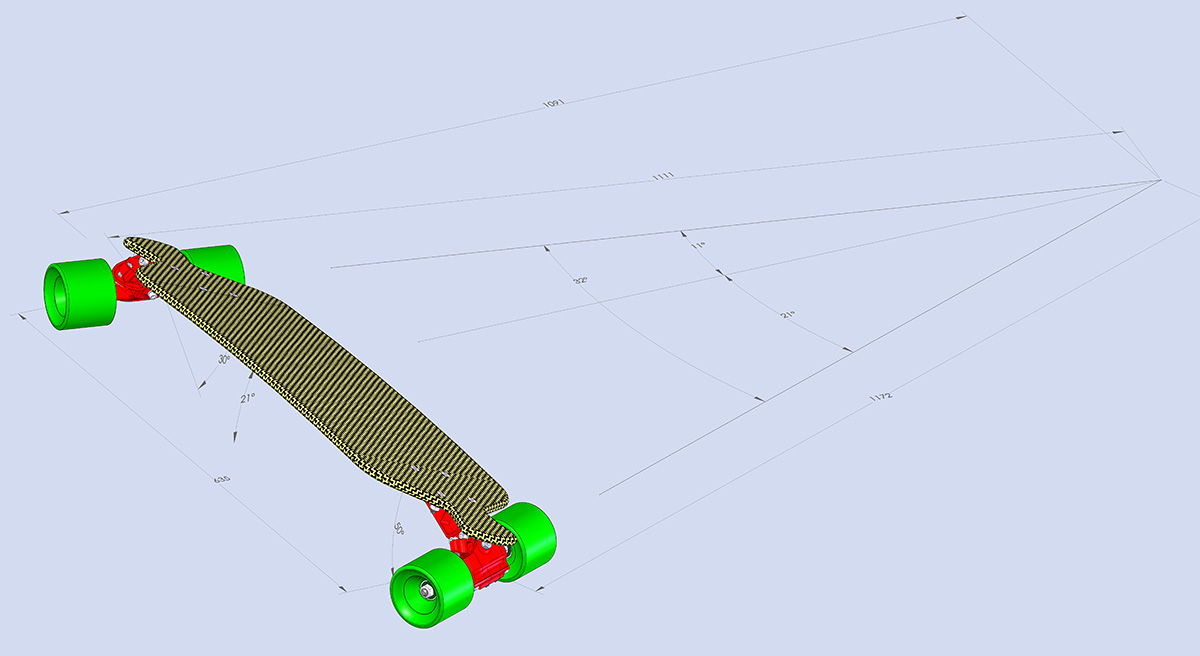

I sat down with a copy of AutoCAD (this was 2001 mind you) and drew up some plans. I then took the files to a great machinist in town (Pelga Engineering) to cut the parts. Other pieces and parts were sourced and obtained. A prototype version was produced (R1). The trucks were tested and design improvements were made during the 2001-2 racing seasons with the help of professional riders, Terrence Kirby & John Gilmore. Then a production version (R2). Finally, an improved final version (R3). The design was essentially complete although an R4 may one day be produced that will take these trucks over the top with a speed version being incorporated for downhill (70+ mph).

The R3 – The finest skateboard racing truck ever made.

Key Features:

* Exchangeable plates to adjust steering angle (0 to 60 degrees) and ride height (1.5 to 2.5″). Angle adjustment keeps axle at exactly the same position relative to deck.

* 3 position base plate allows for 0.750″ of wheelbase adjustment using just one of either “new” or “old” deck drillings

* Rail mount base plate allows for 2.250″ of wheelbase adjustment using just one of either “new” or “old” deck drillings

* Precise bearing mounted pivot allows for exact steering, even without bushings installed.

* 5 high rebound elastomer hardness’s available for any condition or need

* Elastomers can be exchanged without changing any other parameter

* Heal or toe side bushing preload adjustment

* Offset elastomer bay increased ground clearance from R2.

* Proprietary turn limit screws to prevent any possibility of ‘wheel bite’ or for ‘deck loading’ techniques. Can be set differently on heal or toe sides.

* 8mm precision cut titanium axles with custom washers and spacers for perfect wheel mount. Large end chamfers for super quick wheel changes.

* Optional wide axles for 0.500″ increase in overall width.

* 30 degrees of hanger swing in either direction. Over twice the freedom than any other design

* Custom shock pads for perfect support between truck and deck.

* Stainless steel hardware throughout with locking helicoils on every thread (except axle).

* Extremely light weight and beautiful finish

* Revolutionary design allows for improved deck shape and radical wheel clearance.

![r3[1]](http://www.peterverdone.com/wp-content/uploads/2013/05/r31.jpg)

The real thing in all their glory.

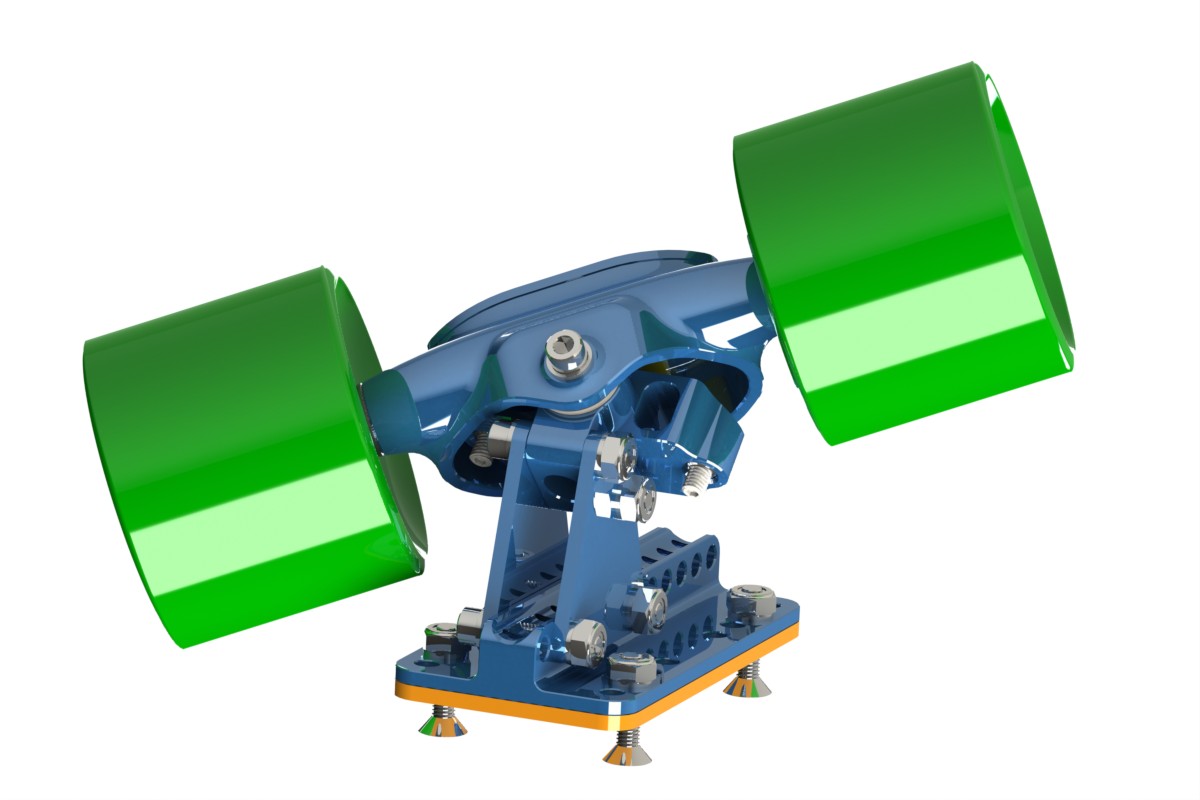

This is is a fantastic shot of the trucks mounted to one of Gareth Roe’s incredible foam core carbon fibre slalom decks and Chris Chaput’s ABEC 11 Wheels. Still one of the nicest skateboards anyone could own.

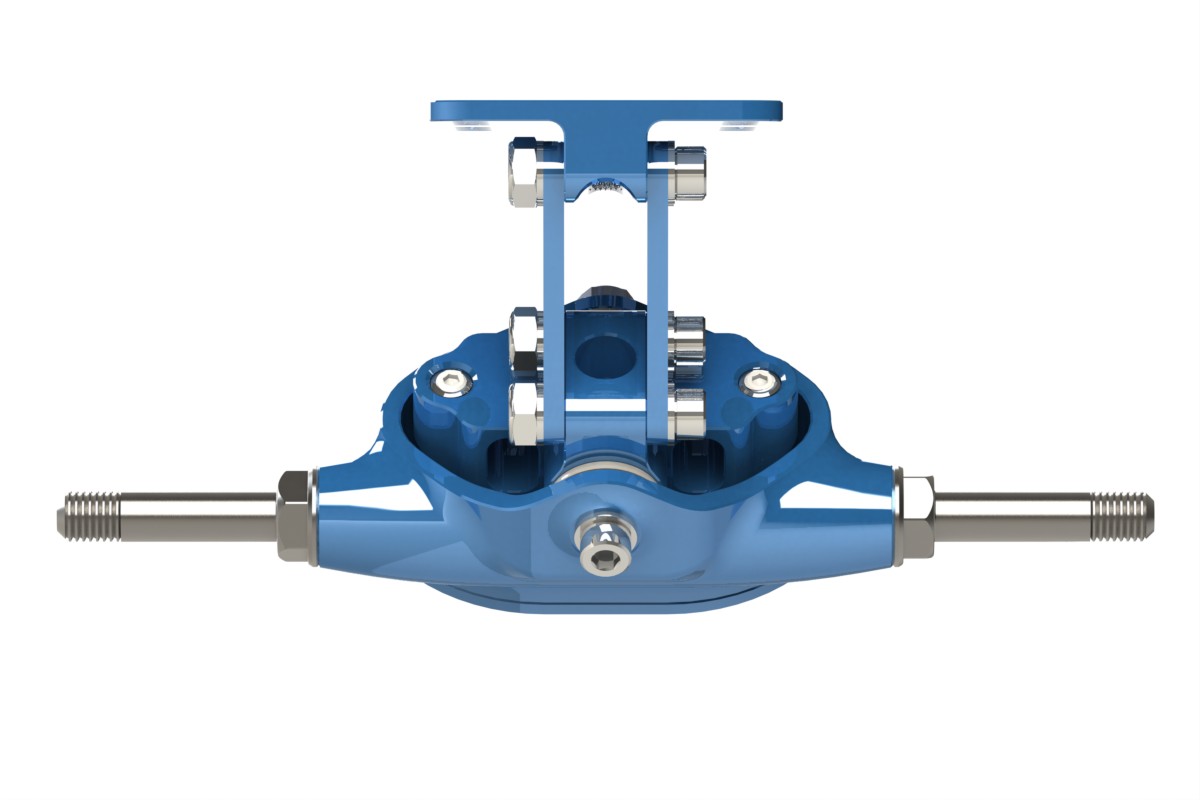

Head on front view showing the curves.

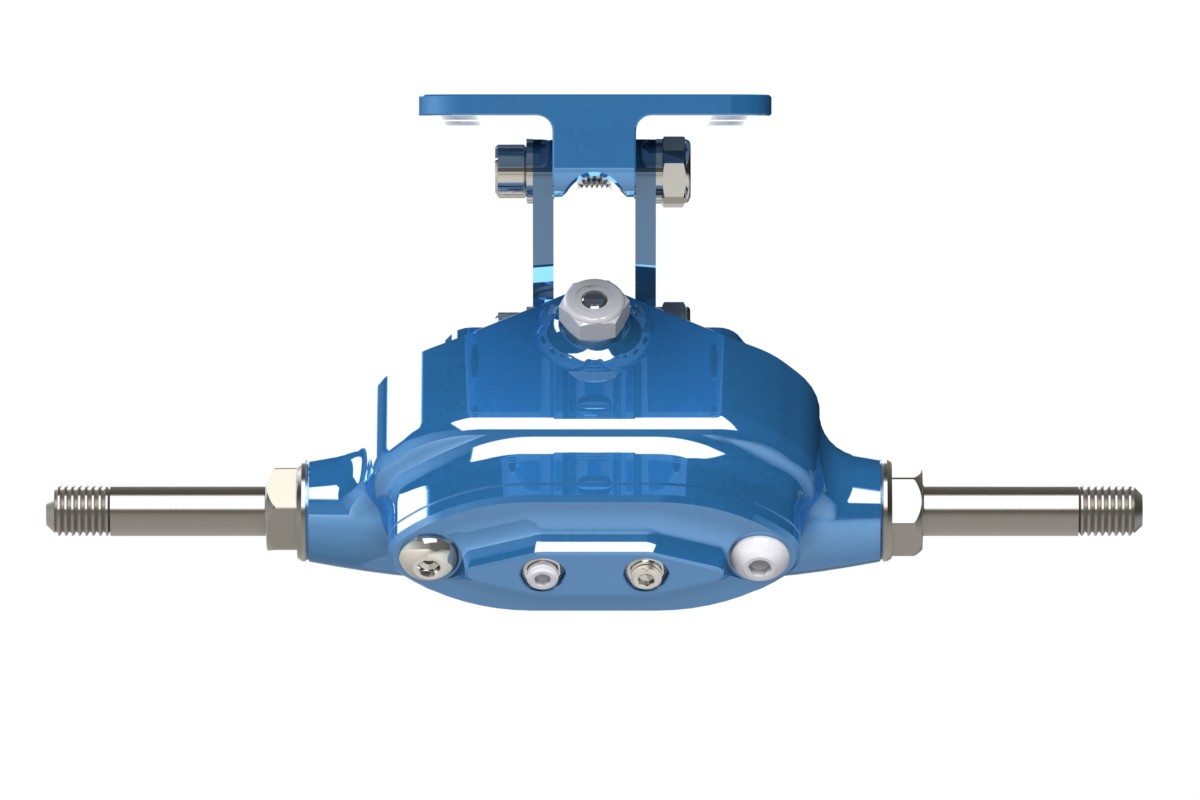

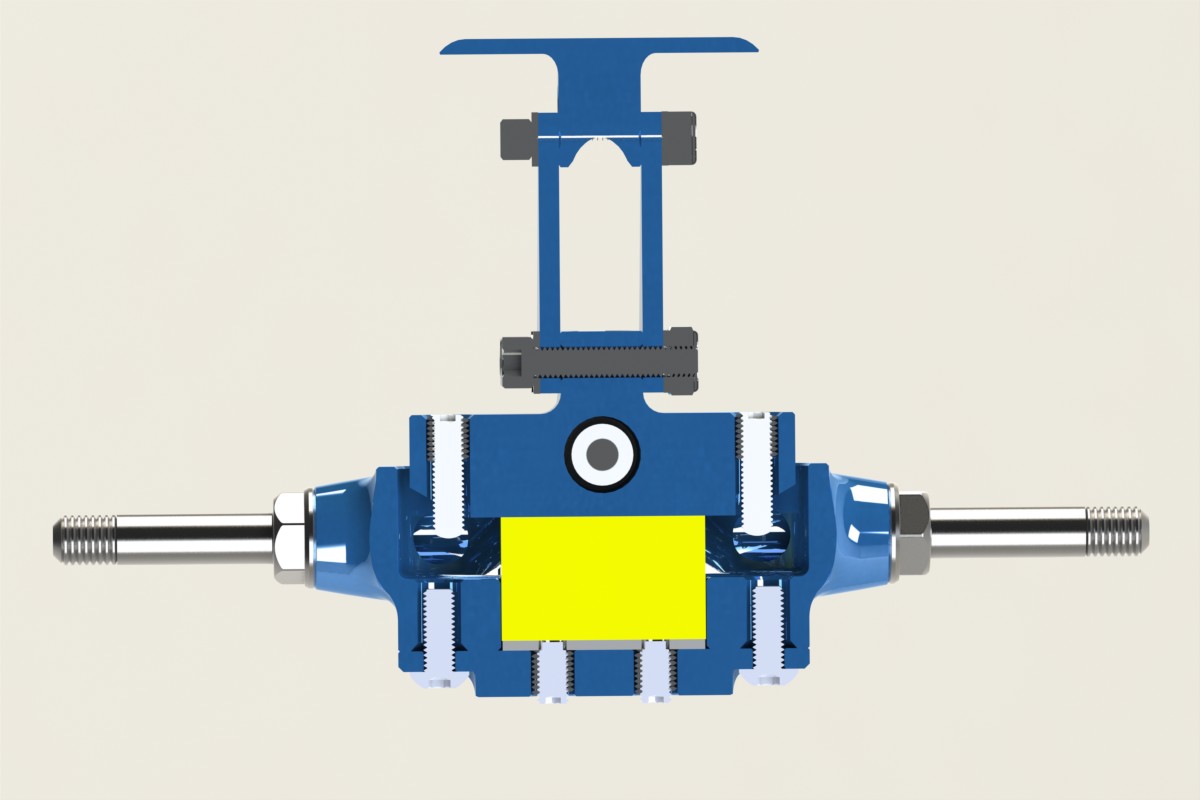

Profile showing the geometry of the truck.

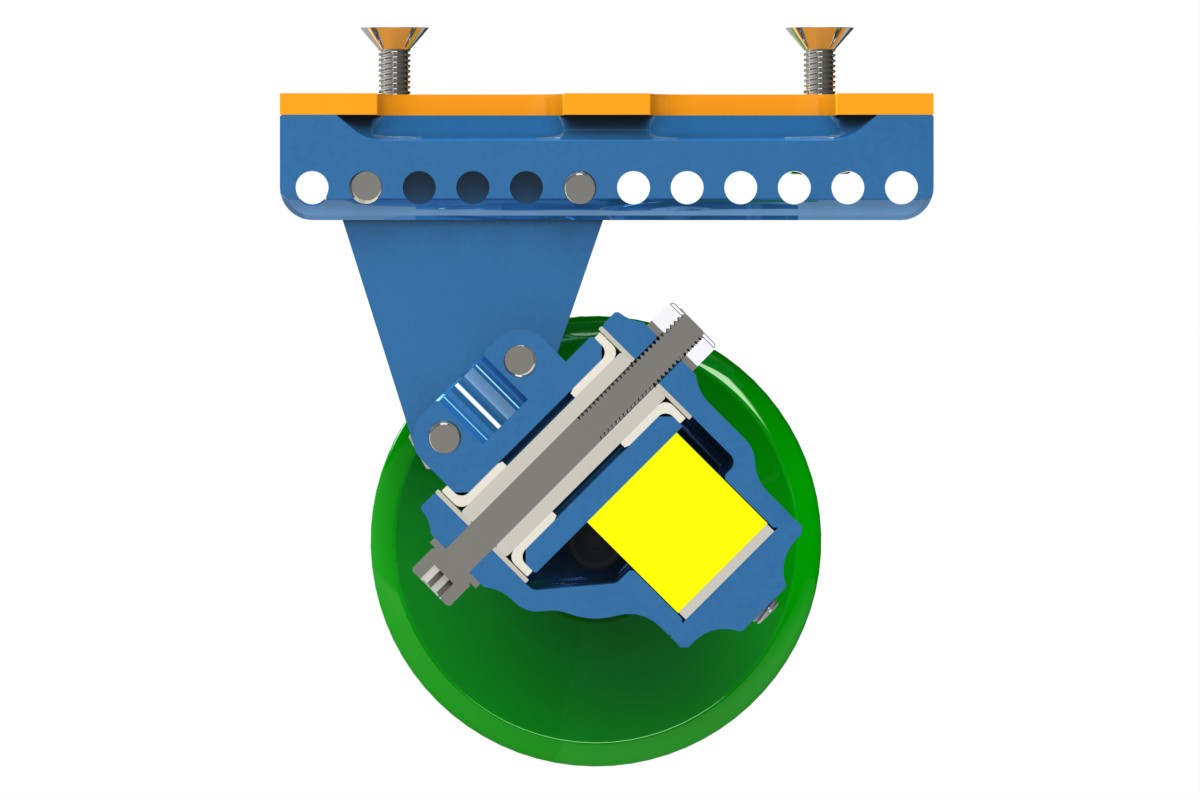

This cut away gives you an idea of the dense packaging that allows these trucks to work so well. There’s not much wasted real estate here.

The limit screws and preload mechanism cut away.

At 30 degrees of hanger swing with large slalom wheels, there is still plenty of mechanical room. No other truck can get even close to this.

Full forward position with standard parts. There’s 3.00″ of wheelbase range for a single truck drilling. That’s important with foamcore boards.

Understanding the effects of the geometry is important. At maximum lean and 30 & 50 degree angle plates this is what we can produce. Incredible.

This shows an incredible configuration. A prototype baseplate moves the truck considerably forward and an astoundingly low 1.50″ axle to plate height. No need for a drop through. Also, the structure of the deck remains intact at crazy leans.

The R2 – The production run. This was a new direction from the prototype with some of the same good features but a lot more flexibility in setup. Using SolidWorks made a huge difference. Parametric modeling is the only way to work. Wide versions were tested on speedboards up over 60mph. Not bad considering these were optimized for slalom. I could do an insane dedicated speed setup.

Key Features:

* Exchangeable plates to adjust steering angle (0 to 60 degrees) and ride height (1.5 to 2.5″). Angle adjustment keeps axle at exactly the same position relative to deck.

* 3 position base plate allows for 0.750″ of wheelbase adjustment using just one of either “new” or “old” deck drillings

* Rail mount base plate allows for 2.250″ of wheelbase adjustment using just one of either “new” or “old” deck drillings

* Precise bearing mounted pivot allows for exact steering, even without bushings installed.

* 5 high rebound elastomer hardness’s available for any condition or need

* Elastomers can be exchanged without changing any other parameter

* Heal or toe side bushing preload adjustment

* Proprietary turn limit screws to prevent any possibility of ‘wheel bite’ or for ‘deck loading’ techniques. Can be set differently on heal or toe sides.

* 8mm precision cut steel axles with custom washers and spacers for perfect wheel mount.

* Optional wide axles for 0.500″ increase in overall width.

* 30 degrees of hanger swing in either direction. Over twice the freedom than any other design

* Custom shock pads for perfect support between truck and deck.

* Stainless steel hardware throughout with locking helicoils on most threads (except axle).

* Revolutionary design allows for improved deck shape and radical wheel clearance.

Problems:

* Heavy. Way too heavy for me, but similar to what others were doing in terms of weight.

* Not all threads were helicoiled. Helicoils are good.

* 8mm axle threading was a bad idea as hardware is hard to find

* Axles didn’t really require LHT on one side and made trucks hard to work with.

* Width change axles were not well designed

The R2 truck.

Moving to a real solid modeling package allowed me to do things virtually that I couldn’t prior, either in the computer or outside. For example, a graphical map of the steering components that took into account every bit of geometry in the system. Before that I was restricted to spreadsheet calculations and some very complex trigonometry and calculations. ![turning-geometry[1]](http://www.peterverdone.com/wp-content/uploads/2013/05/turning-geometry1.gif)

![skateboard-turning-calculat[1]](http://www.peterverdone.com/wp-content/uploads/2013/05/skateboard-turning-calculat1.jpg)

The R1 – Essentially a prototype. 5 pair were made I think. Using AutoCAD as a solid modeler was a mistake I refused to make again and this ensured my purchase of SolidWorks for the next round. The design was crude and not very user friendly. A simple vernier bolt patter made angle adjustment possible for every 5 degrees from ### to ###.Still, they were essentially prototypes and proofs of concept that showed some good was there but also that software was an issue as were some assumptions.

Key Features:

* Vernier bolt pattern to adjust steering angle (? to ?? degrees). Angle adjustment keeps axle at exactly the same position relative to deck.

* 3 position base plate allows for 0.750″ of wheelbase adjustment using “old style” deck drillings

* Precise bearing mounted pivot allows for exact steering, even without bushings installed.

* 3 elastomer hardness’s available

* Heal or toe side bushing preload adjustment

* Proprietary turn limit screws to prevent any possibility of ‘wheel bite’ or for ‘deck loading’ techniques. Can be set differently on heal or toe sides.

* 8mm precision cut steel axles with custom washers and spacers for perfect wheel mount.

* 30 degrees of hanger swing in either direction. Over twice the freedom than any other design

* Custom shock pads for perfect support between truck and deck.

Problems:

* Vernier system didn’t allow for full range of angle, ride height, or wheelbase adjustments.

* Prototype elastomers had much too low rebound

* Elastomer swap required releasing preload and dismanteling pivot