The skate truck project continues to move forward in the background of the other big projects and developments. Nothing ever stops. Movement is important.

Initial designs for the G6 started almost as the G5 trucks got finished. I had a lot of ideas that I wanted to get ‘on paper’ when I was setting them up. I put a week or so into that but then everything was tabled for a half dozen months while I worked on a bunch of bike stuff. I finally got back into this a month or so ago.

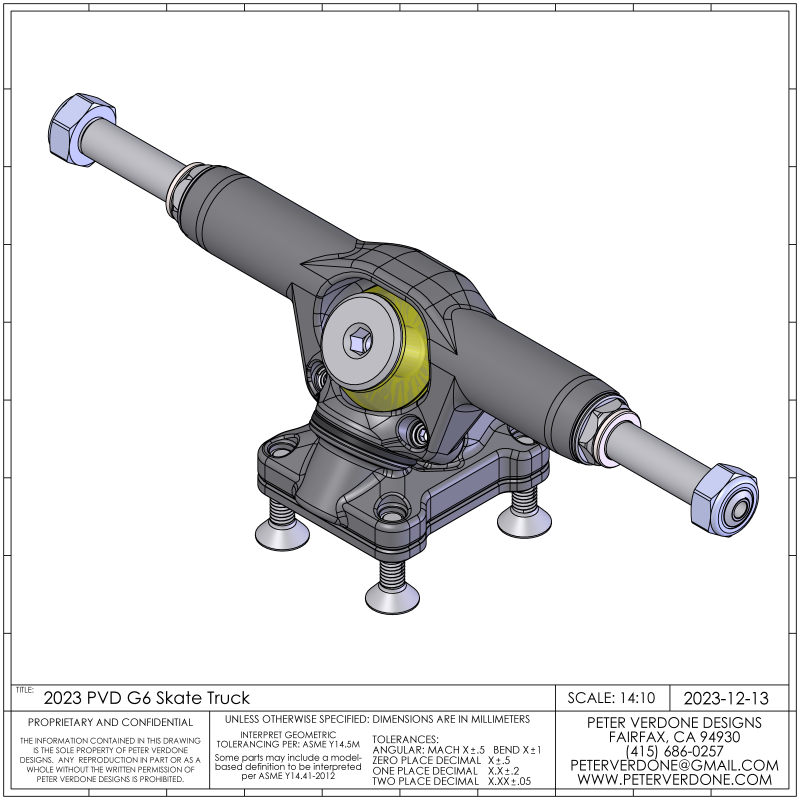

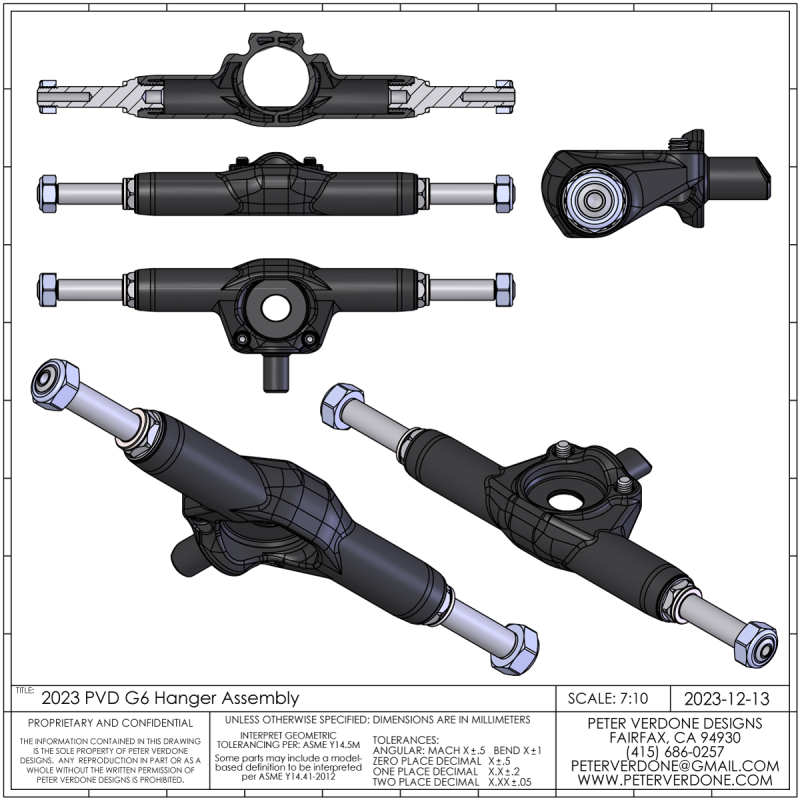

That time off was helpful. Even as I had done considerable work on the G5 design, I saw things very differently. I put a few more weeks into the new trucks. As usual, there was a big dig into the modeling architecture and methods. The shape of both the baseplate and hanger are extremely refined over even the G5 truck.

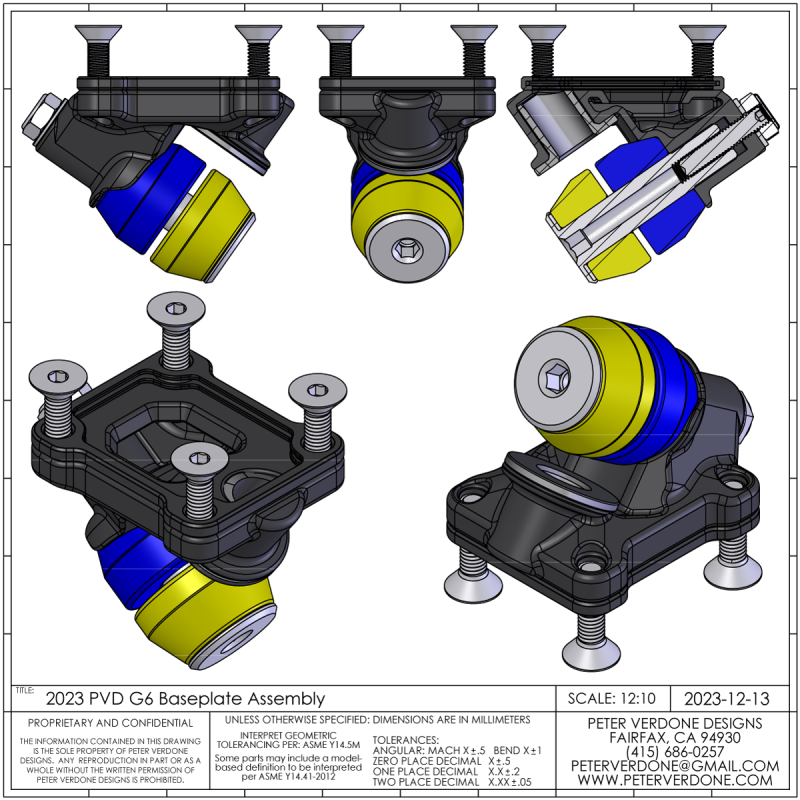

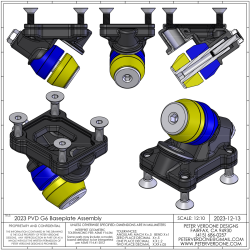

I wanted to keep as much clearance under the truck as possible. This is important when cruising messy streets that have trash and junk on them. That meant a bulb is formed around the bushing mechanism. This gives space to support the loads on the hanger but raises space every where else. I don’t like the looks but there is meaning for it.

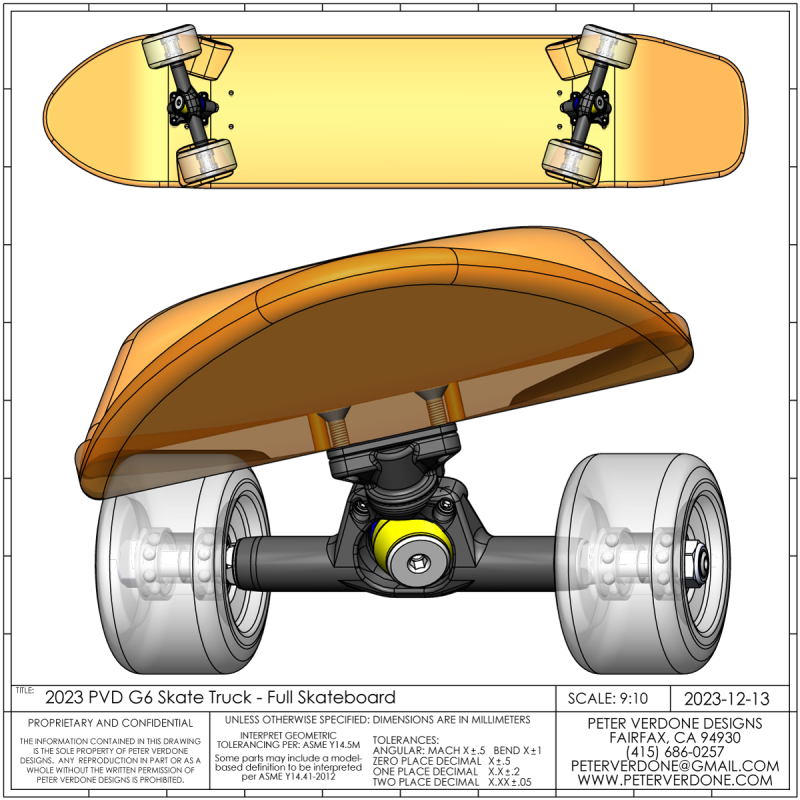

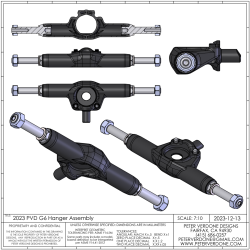

I shaved a few millimeters from the footprint of the baseplate while keeping the 36x30mm drilling. These trucks seem tiny, but the width of the hanger is still 118mm.

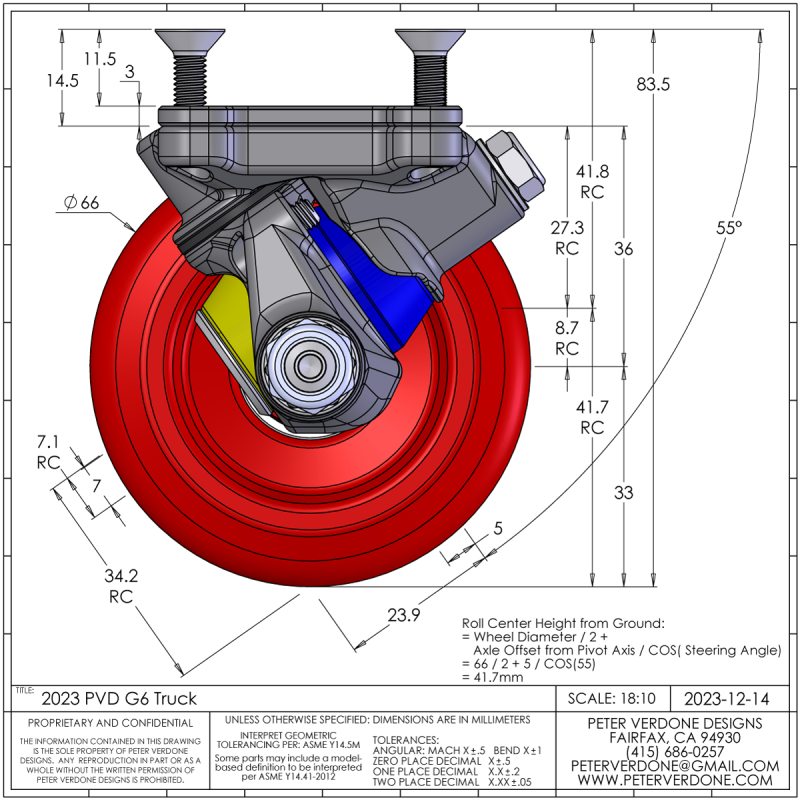

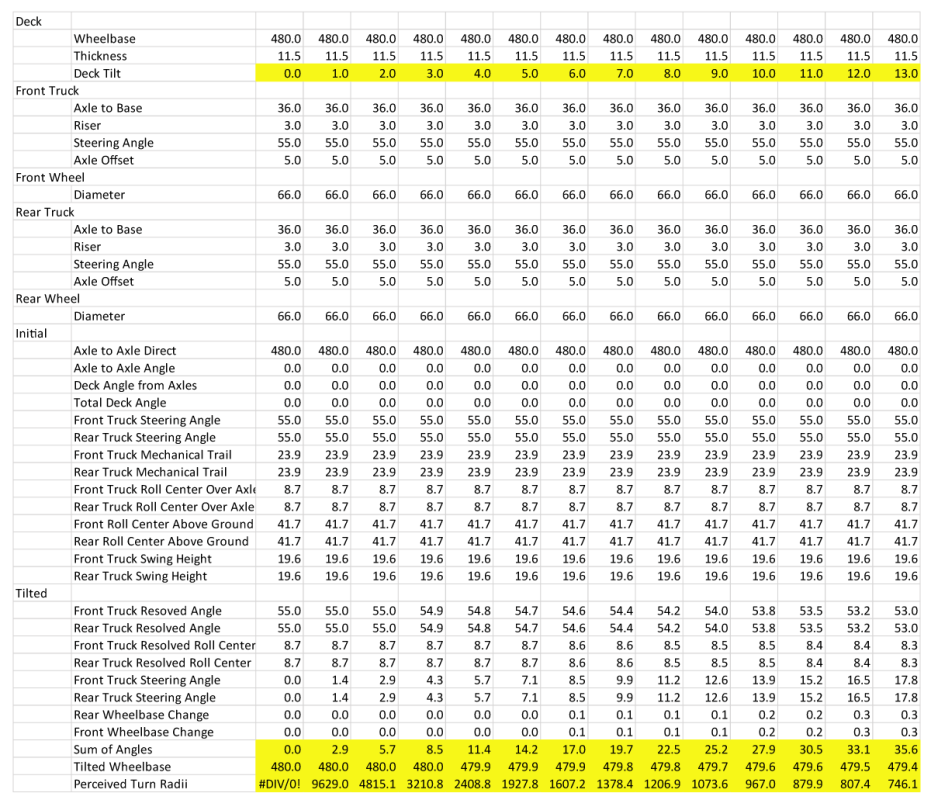

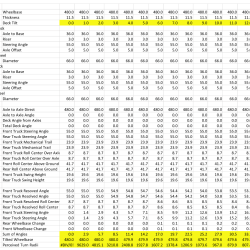

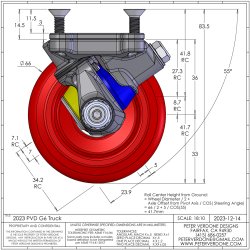

The steering geometry changed slightly. I wanted to lower the roll center some so the axle is offset from the pivot 5mm instead of 6.5mm. Now, the roll center is 41.7mm from the ground. This will give a lot more traction and hopefully a nicer feel.

The G5 trucks had an issue with the kingpin. Holding the kingpin by the threads and with a locking heli-coil produced so much movement over time that most of the precision feel that could have been was lost. I needed to fix that. This is a tricky problem as the pin has to be removed to change the bushings and to do that without removing the trucks from the deck means that everything has to be done from the top or exposed.

The new kingpin arraignment is much nicer. I moved to a fully machined pin that is cut precisely to 0.375″ diameter. This is larger than what your average 3/8″ bolt would have, increasing the stiffness and fitting tighter on the bushings. It fits into a deep bore in the baseplate with a set screw and nyloc nut passing to the outside. This fixes the pin and allows for adjustment. There is very little play. I’m keeping my eye on this as the truck is used.

The limit screw system was revised. Now, the trucks allow for a 21 degree internal hinge in either direction. This translates to about 12.4 degrees of deck tilt and a minimum turning radius of about 782mm given the 480mm wheelbase.

I also folded into the project is a master model method into the architecture of the file structure. I did this with the M2-F2 bike modeling and now I’ve brought it to the skate stuff. I’m really liking that I have a single file that contains all of the geometry and construction detail for the entire project that can be instantly passed on to any individual component, even the most mundane. Using this method, complex models generate far faster and changes propagate among all of the parts regardless of being contained in an assembly. It’s nice.

I will say that even though I’m using a dated version of SolidWorks, the program really needs to do more to make this method more intuitive and easier to navigate. Generally, any work with configurations, equations, master models, and sub-assemblies is difficult and challenging. Be careful as you trod into these regions.

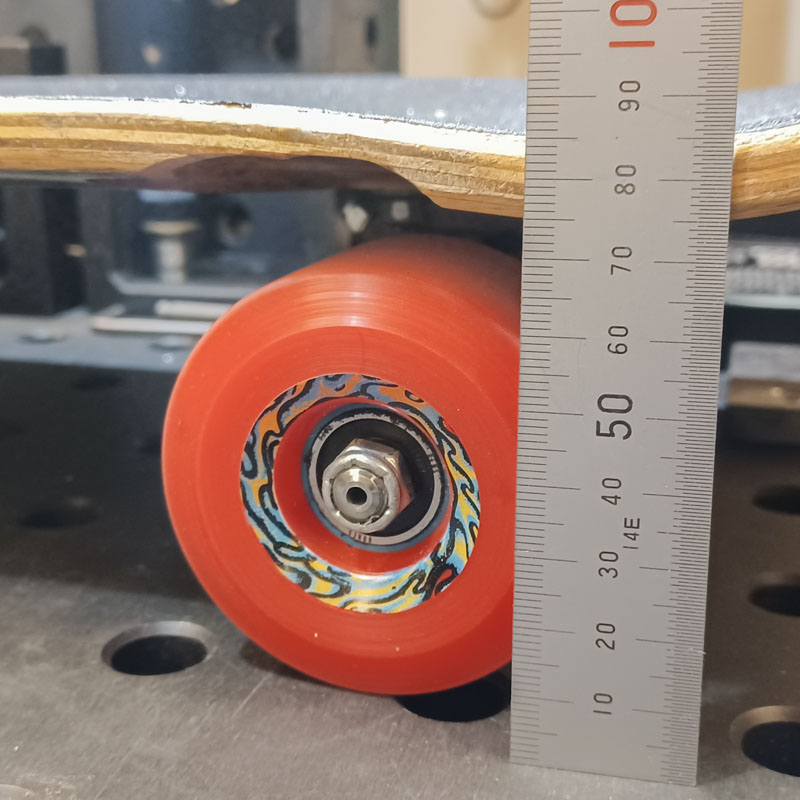

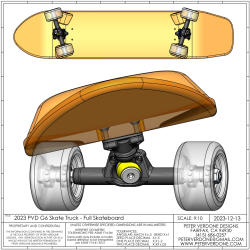

I liked using the 69mm wheels with the G5 trucks but I really couldn’t stand the height that was required for that. I decided that I’d move back to 66mm wheels to get back the low feel that I love. The difference between the two is staggering. This is a real value proposition in my work. The reduced weight and inertia of the smaller wheels is nice as well.

The baseplate assembly. This is a very cool part. So much is packed into this area.

The hanger is wild as well. Smaller and stronger. I want it to be so tiny!!

The feel of the trucks is pretty awesome. The precision feel is working in the way I’ve been searching for. The swoop is nice. I’m feeling very connected to the ground in a nice way. I’ve still got some more setup to do around the bushing tension setting but I’m excited to put some miles on these trucks.

Setup and testing of the trucks went as expected. The limit screws are adjusted while the trucks have very little preload on them. Then the preload is set. The action is very crisp. They really have a precision feel to them. It takes very little motion to initiate a turn. It seems that any amount of tilt results in the axles changing angle.

Going with the lower setup was the right choice. The height advantage is noticed far more than the loss of a few mm in wheel diameter…at least for what I’m doing with this deck. Those that haven’t ridden on a skateboard with a very low deck height are really missing out. Especially for those of us that are just pushing around and cruising, it’s the only way to fly.

I realized that the addition of a fiber washer between the preload nut and the baseplate may help isolate the two parts that may be moving relative to each other. It’s been added to the next McMaster order.

On another iteration, I expect to add more of the kingpin fit preload shaping that I added to the bushing pockets. This is good. More may help. It could be accomplished by increasing the diameter of the kingpin, but I feel that keeping that pin at a nominal 0.375″ has value.

It might be time to do some work on de-tuning the rear truck. A 50°F/50°R setup even with this 580mm wheelbase kicks a little hard at maximum steer. I call this ‘car steering’. 5-10° less angle in the rear truck may help with that high side feel. Another good thing having to do with this change is that it’s far easier to take angle away from the truck and keep the primary geometries similar than it is to add more angle.

Softening the fillets on the outside shape of the limit screw boss area would help the aesthetics and touch of the trucks. The G5 was nice like that. It may take some work to get that to happen while keeping the overall size down.