The KS LEV 27.2 Integra post is a great problem solver for older fashioned and light bikes that use 27.2mm seatposts. I certainly wouldn’t design a bike with one of these in mind but they do solve problems. These days, 150mm of drop is considered average. 100mm is simply minuscule.

The big problem with these posts is return speed. I solve that issue.

Speeding up a KS LEV 27.2mm post:

Stiction:

Make sure your post is properly lubricated with Slick Honey. Stiction is the biggest enemy of the LEV posts.

Full stroke lever:

Make sure to use a control lever that provides the maximum cable pull possible. A KS Southpaw or similar lever is the strong preference. A short pull won’t open the valve very much.

Pushrod length:

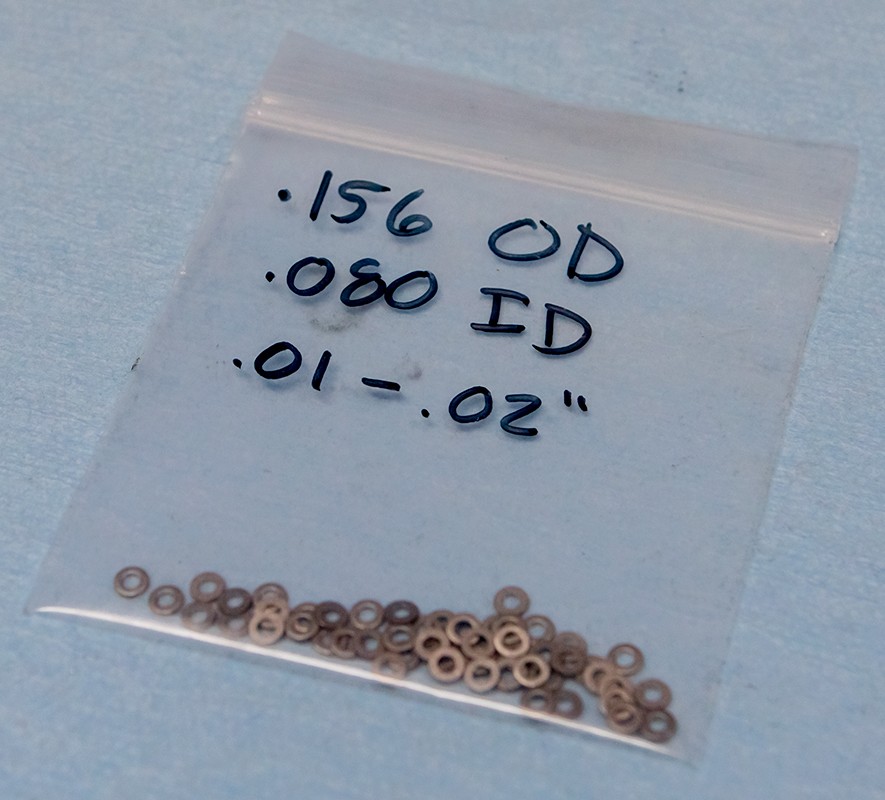

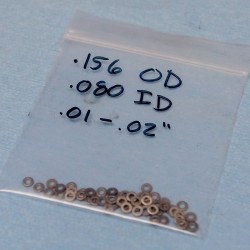

The quickest and most effective way to help increase speed of the 27.2mm post is by tuning the push rod shaft length. You can cut special rods or just shim it with some tiny washers. My unit was shimmed up from 198.80mm to 199.75mm. It helps open the valve sooner and more than if left un-tuned.

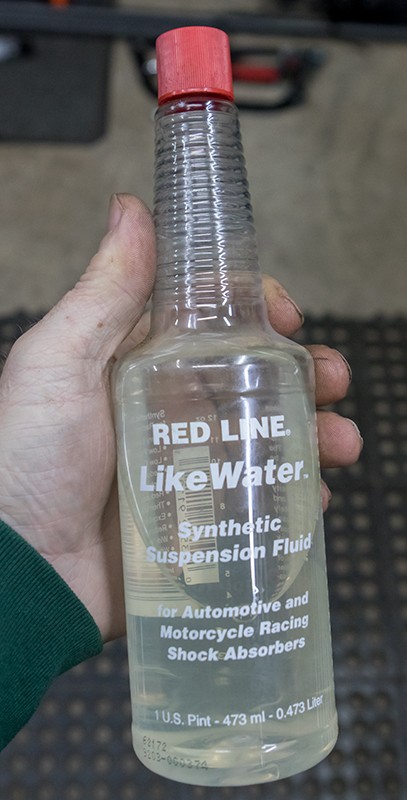

Damping fluid:

For this post, you want the lightest fluid you can use; Red Line LikeWater! It will help with some internal friction and speed up the damping. This is the good stuff.

Air Pressure:

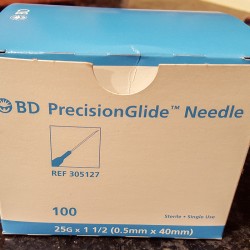

Air pressure needs to be boosted up to 250 psi to get some real life from this post. It’s set fairly low at the factory. The air seal really doesn’t have to be broken for the damper tune but here it does. Begin by removing the epoxy that covers the access hole. The seals in the head will act in one direction so you just have to get up to pressure behind this hole. For this I construct a sealed beam with the needle projecting into the hole. It works great. You don’t need to dismantle everything unless you want to. I tried a few different techniques before figuring the last one. A 25g x 1 1/2″ needle works well. The hole is very small, 0.025″.

Notes:

The bearing over the threaded section connecting the air chamber and the damper will be pushed out once you start screwing them apart. You don’t need to put the bearing back in place (in fact, it will be an issue). Just forget about it. The hole it exposes is very handy when assembling the damper with an assembly bleed.

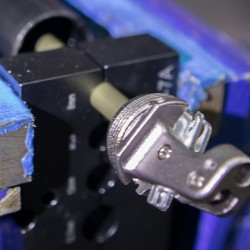

You can open the air can using a right angle snap ring tool against the 15mm hex. The large Allen was just used my first time disassembling the unit. The torque required for all of these connections is very low. If you feel it’s good enough, it is.

A quality set of shaft clamps and the right snap ring pliers will make life come together for this.

Damper assembly bullets really make a difference when putting these together. More so than the larger posts.