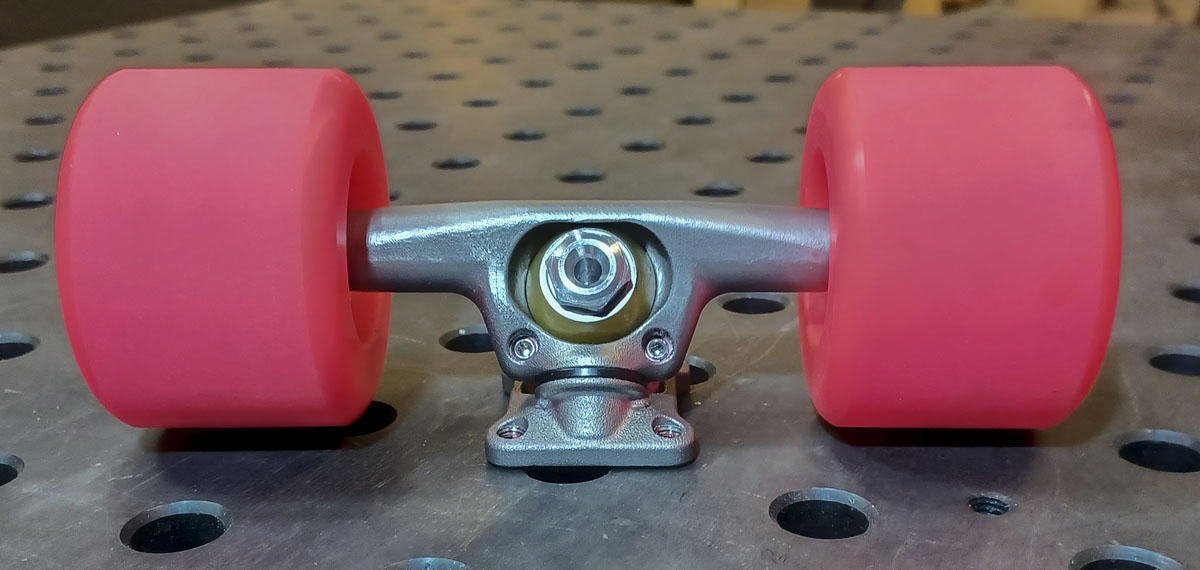

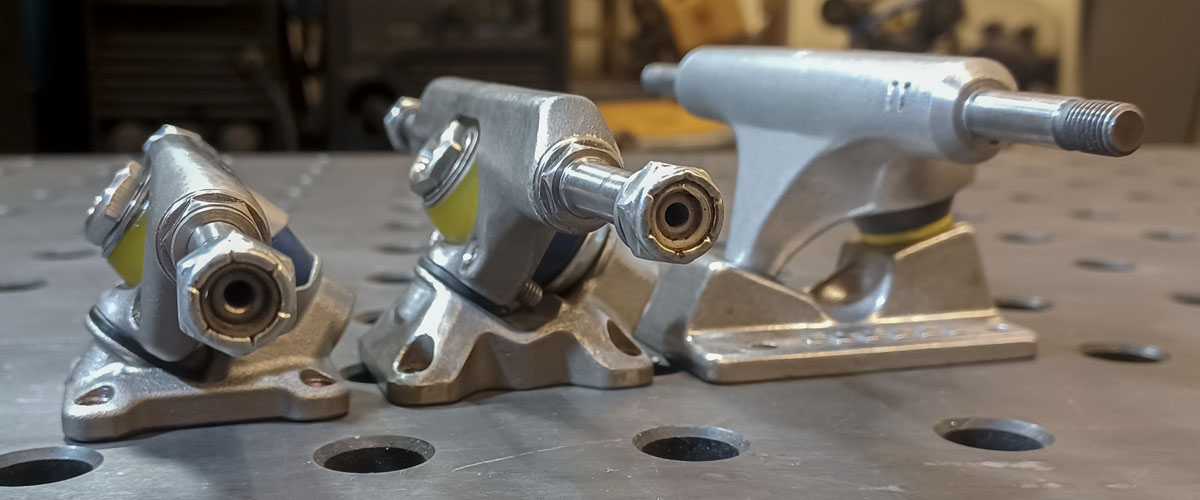

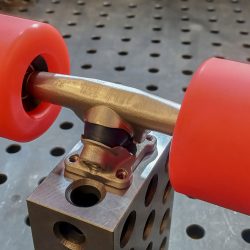

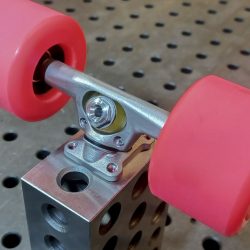

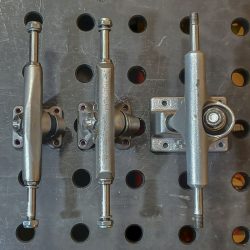

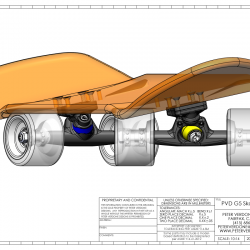

Here we are again. Another draft of the skate truck. They are getting pretty.

The G4 trucks were working very well and there had been enough time on them to figure out what needed to change next. Functionally, they were pretty good but there was still room for improvement.

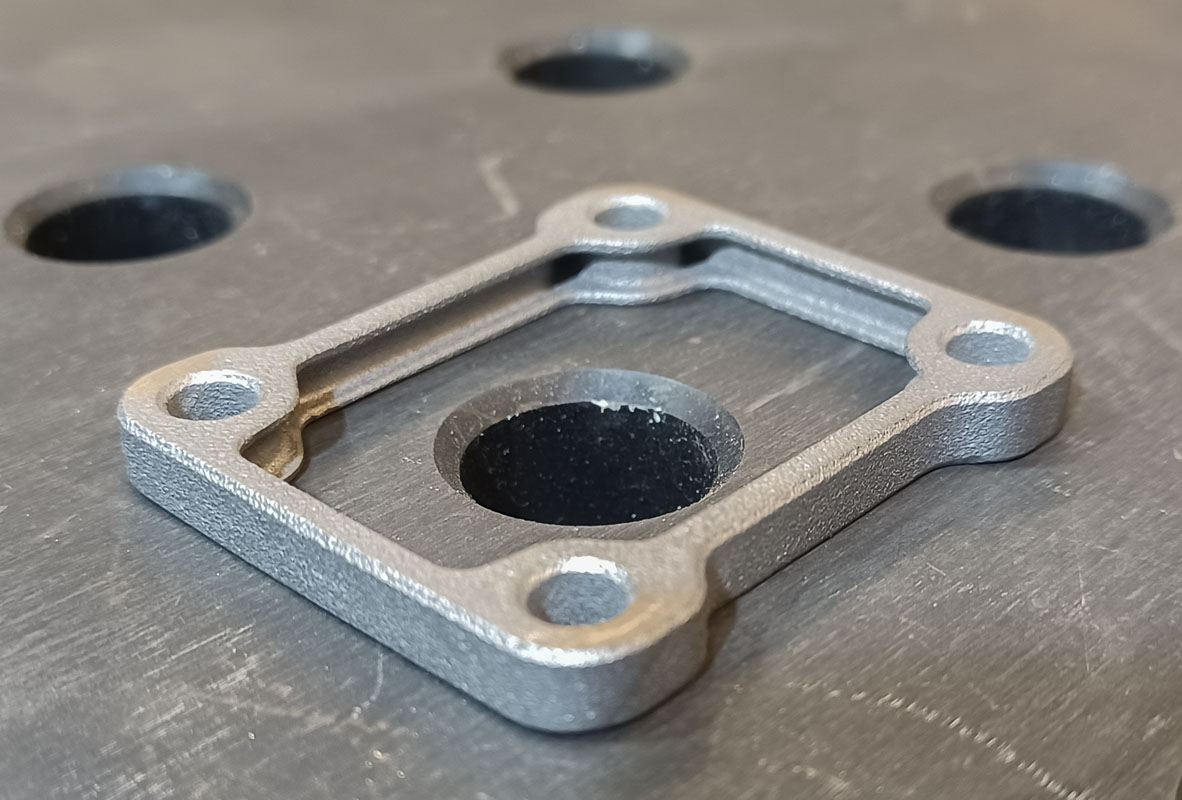

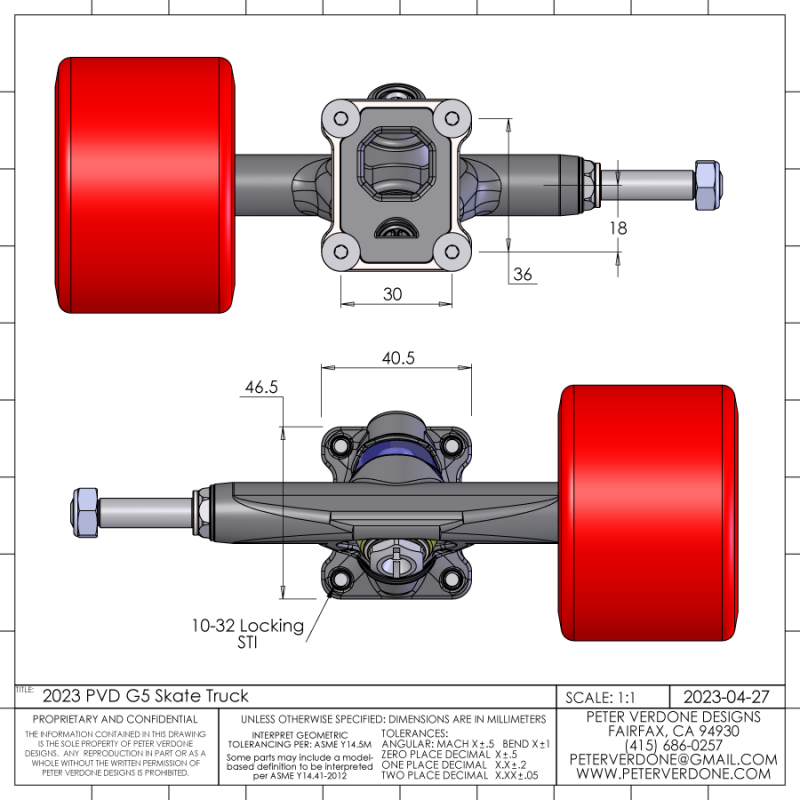

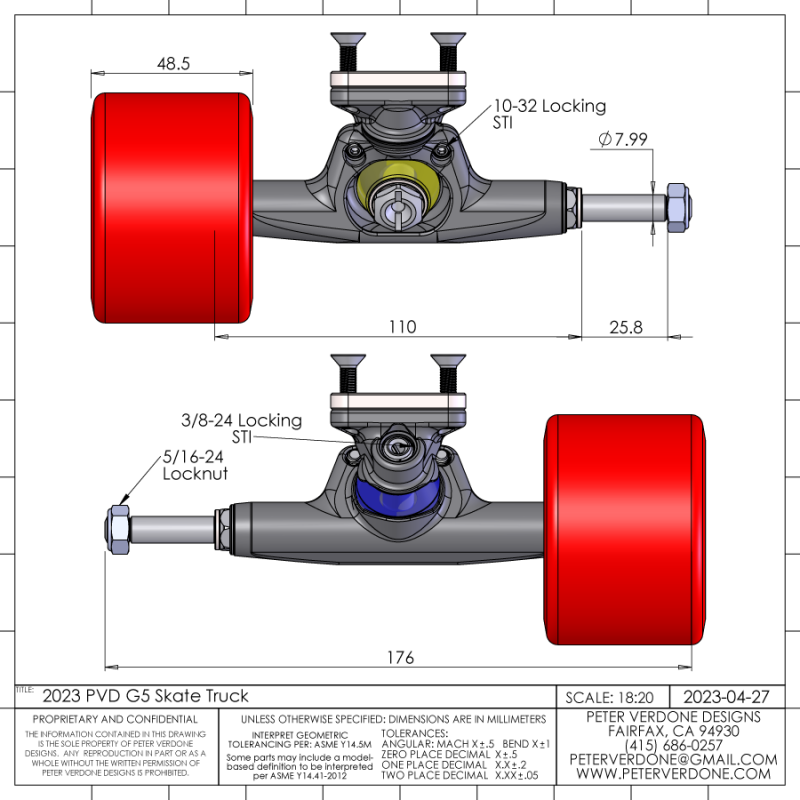

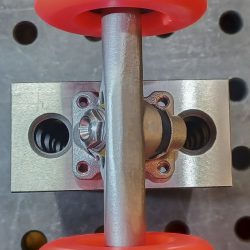

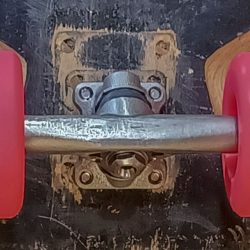

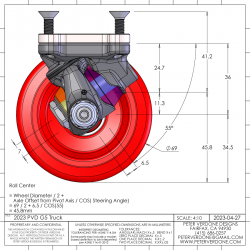

I had some changes to add to the pivot bearing. I increased the size of the thrust flange for improved precision in the action. These are now at near precision truck levels of action. It’s amazing how much the pivoting action stays true.

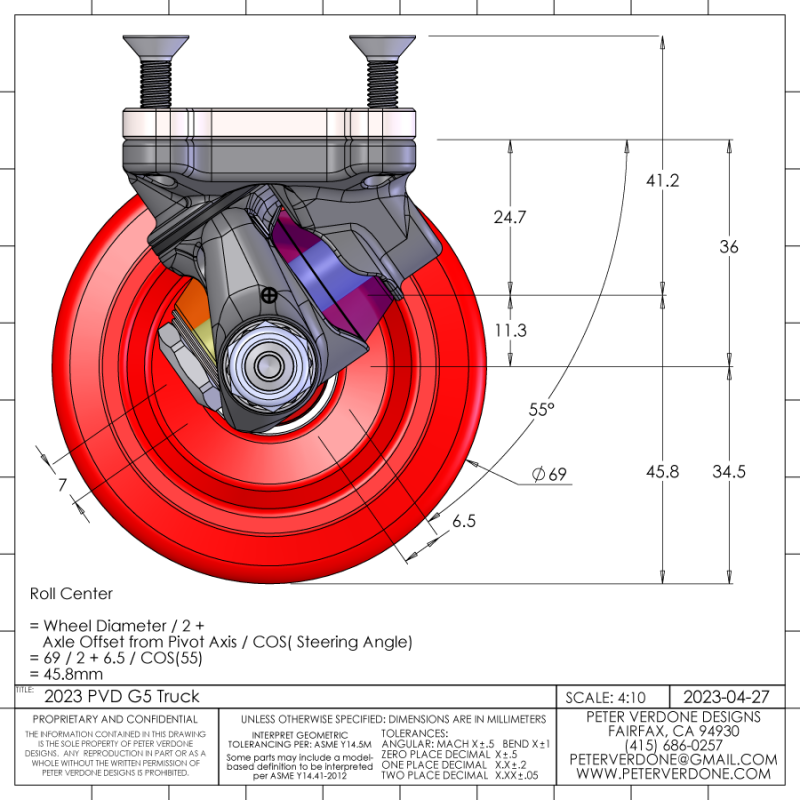

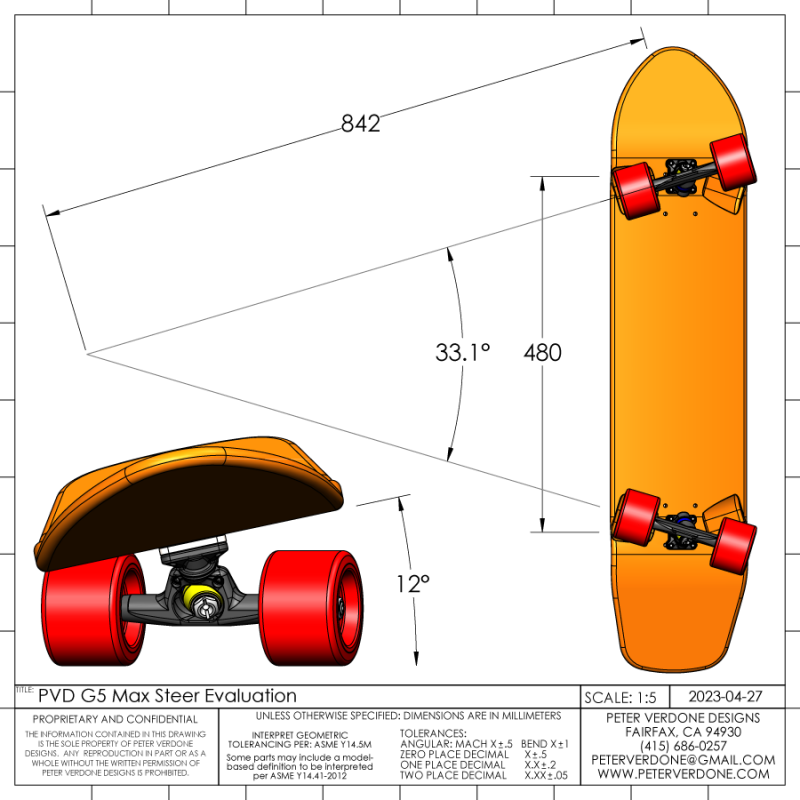

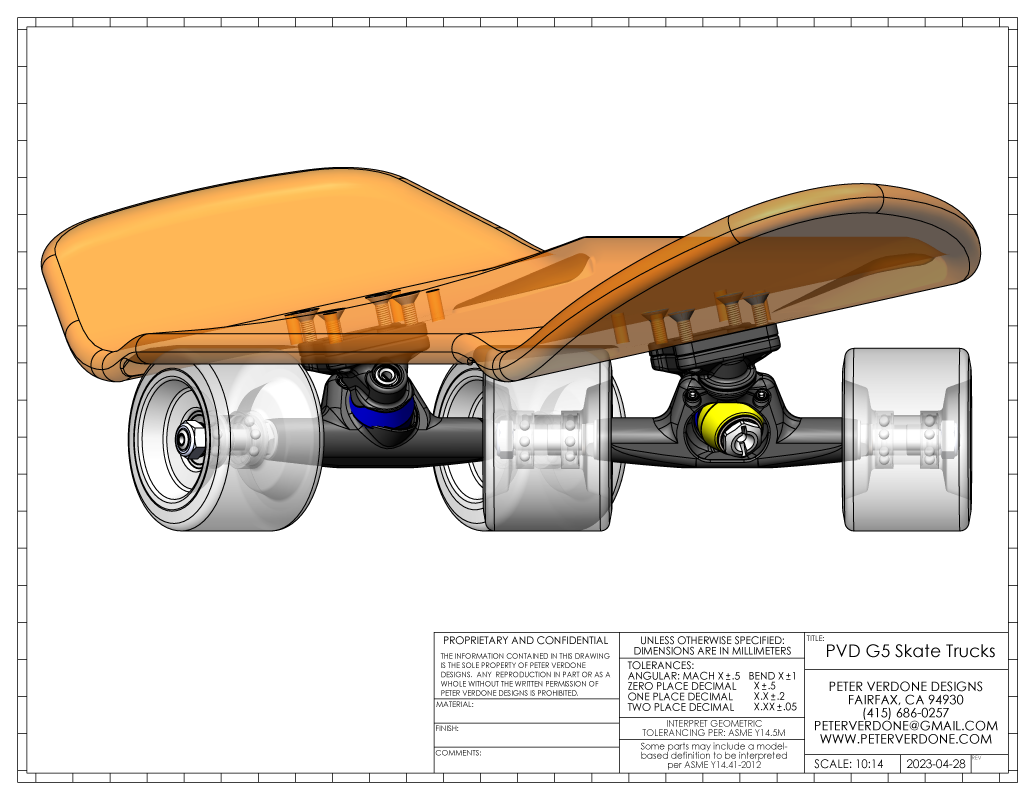

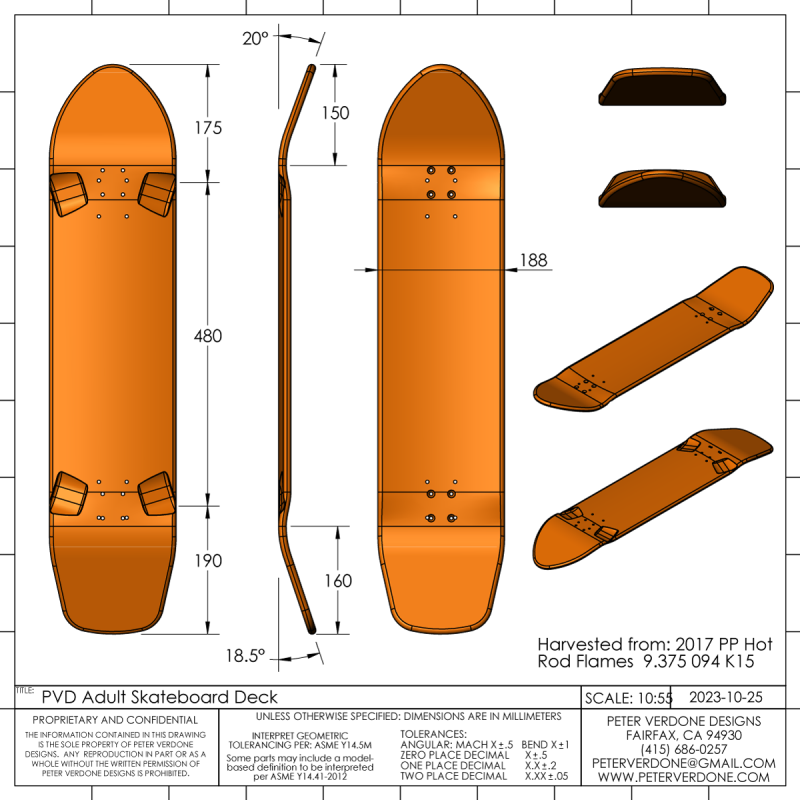

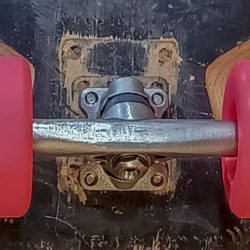

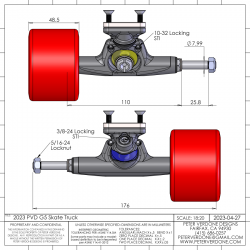

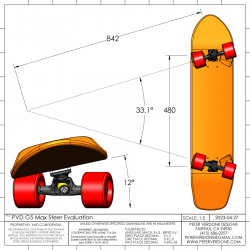

I wanted to move to a larger diameter wheel. Now 69mm. That inspired a change in geometry to keep the roll center in approximately the same height above the ground from what I had for the G4 trucks. This would keep the traction and carve feel with a bit more swing for the deck.

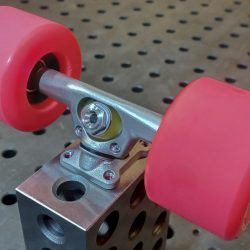

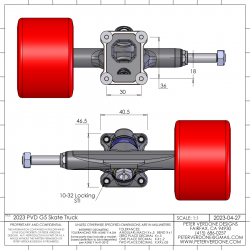

Otherwise, the truck was ultra-minuratureized. I tried to reduce the mounting height of the truck to the absolute mechanical minimum. Eliminating the use of risers was a mistake and prevented some tuning opportunities. Almost everything shrank in some way. As usual, the models were improved and new methods were learned. Shrinking the truck made them much better from a design perspective.

Even the mouning pattern shrank, now 30x36mm from 34x40mm. This is a tiny setup!

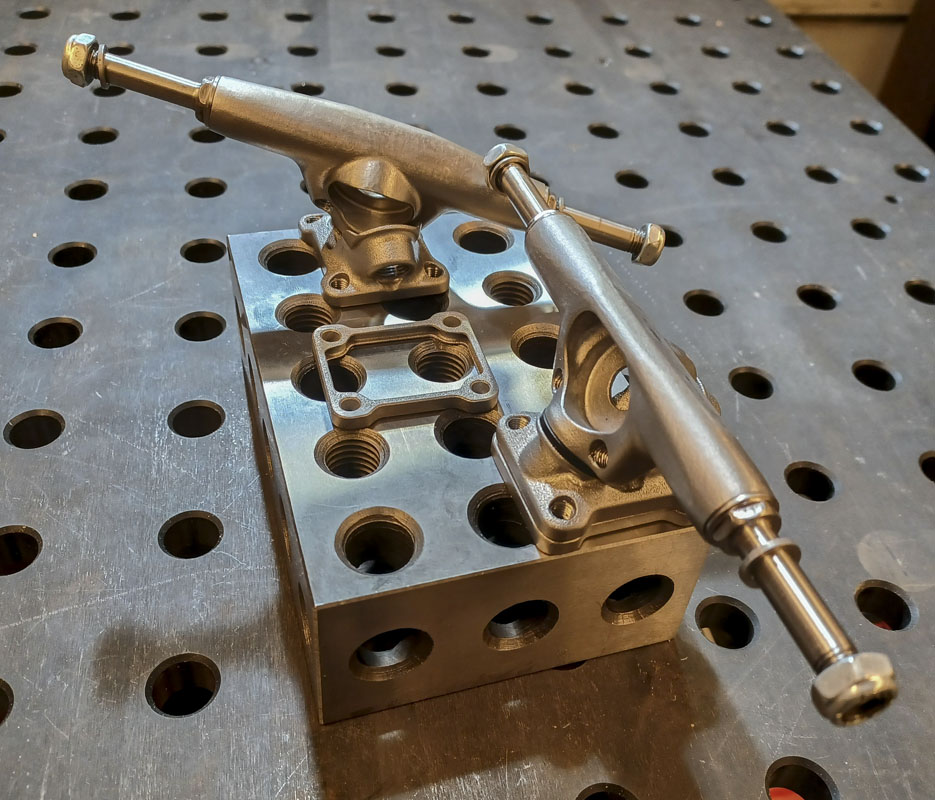

I did a few other new things in this round. I printed some nice risers for the trucks and a tool that would help hold the hanger while machining the axle threads. I also specified a glass bead blasted finish on the parts. I’d highly recomend that for parts that are expected to be left bare. It looks a lot better than sand blasted.

I am still contending with finish quality and distortion in the parts. These trucks look ‘ok’ but I’m still expecting that better should be possible. Is it my vendor? My models? My expectations? I would love to find out what others know that are getting higher quality prints.

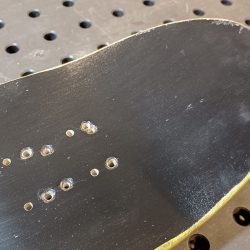

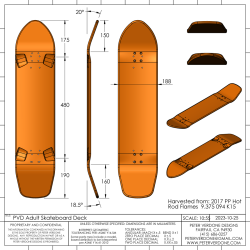

The change in mounting pattern forced me to finally get around to filling in all of the holes in the test deck. This should have been done long ago. I sourced some maple rod from McMaster and glued them in place with a tight hammered in fit. Then I was able to do the new drilling with my fancy tool.

One final step before mounting the trucks was to modify the wheel wells on the deck to account for the geometry and wheel size changes. This was just done with a die grinder for expediency. I was suprised by how well this turned out when cutting by hand.

I got the previous versions of the trucks together to take photos. Now that I’m 5 rounds into this project, it’s interesting to see the progression. I’d say that the trucks really started getting good in the 3rd round. I’m hoping that this (5th) round is a leap in getting to a much more highly refined state. I especially focused on the difference between the original ACE truck that I was using and the G4 and G5 truck.

Setup and shakedown:

It took some time to get the trucks set up. The big wheels and low height mean that there is very little room for error. I should have made the riser about another 0.75mm taller. Maybe a full millimeter. Still, eventually I was getting close to the right feel.

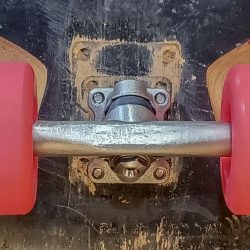

The problem is the wheels. These wheels really feel like crap in this setup. They weigh a brick ton so pushing feels heavy as hell. The amount of friction they create really slows things down when the truck is pivoting. It’s obvious that the only significant next step in the development is to fix the wheel problem.

The good side, in my quick evaluation, is the pivot. That is very nice. It feels VERY precise. I feel like this is as far as this part of the design needs to go for now. It’s great. It also looks amazing.

The compactness of the trucks is exciting. They look light. The modeling is so space age. Smooth edges and a bulbous yet delicate look. Yes. The choices made here were all good. It may be time for a bit of textural flair on the big flanks of the hanger.

I’m thinking of trying a grind of some wheels and ordering some wider hangers and another riser size when I place another print order for my next mountain bike design. That means seeing parts in a month or so. Not sure what I should do in the meantime other than just ride it.