A couple weeks ago, I was at an event mingling with many notable California bicycle frame builders and part designers in the custom frame building community. It was a great event where we did a lot of talking about the work of one man. He will be missed.

One of these conversations was with a well-known builder that I happen to adore; talking about handlebars and the T47 Airspeeder setup that I had brought. The bike was currently configured for trail use, with larger knobby tires, wide flat bars, and a relatively small 36 tooth chainring. I had been out testing the bike on Mt. Tam the day before. Feeling how well it handled the nearly one thousand ess turns on a trail that goes from the top of the mountain pretty much straight down to the bottom. It’s a legitimate singletrack trail with all the fixins: DH segments, loose shale swaths, deep rut corners, and steep grip-less chutes. It was hard work to ride the bike there, some sections were just frustrating, other terrifying. My arms became jelly.

Just a week before, the bike was set up with custom fabricated bi-plane drop bars, 30mm tires, and a 42 tooth chainring. Those bars were making a buzz online. I was talking with this builder about the several transformations that the bike could take, and where it worked well and where it didn’t. I was stoked to be back on the flat bars after testing the drop bars, commenting that “drop bars are terrible in pretty much every situation EXCEPT when improving aerodynamics”. He took exception to the statement, saying it was really about the rider’s preference. I took exception to his exception. “No. It’s not. When was the last time that you tested flat bars on a road bike, in real anger?” I asked. “Uh, never,” was the response.

Never. He’s never tested it. I had tested the hypothesis and he had not. That’s a kind of knowledge.

I’m certainly not trying to make an argument against the use of drop handlebars here. I am saying that it’s important to understand clearly what we are choosing against when we go with tradition. What parameters are we maximizing and what are we minimizing? We can determine that with testing.

Want some sage words? Here’s something that Dan Kyle (two time AMA tuner of the year) told me – back while I was in his shop learning suspension and tuning tricks – that burned into my brain the second I heard it:

“All the math and science in the world won’t tell you what will work at the racetrack, but it will tell you what won’t.”

Fuck wow! So often, when arguing about performance equipment, the discussion devolves into empiricism vs theory. Some folks say, “It just works, so we do it”. The other side says “This is why it works so we do it” Do we know what we know from experience, or from science? Really, it’s most often both. Dan’s expression seems to bridge the dilemma between the two factions of argument. I thank Dan so much for that as it has guided me in many endeavors.

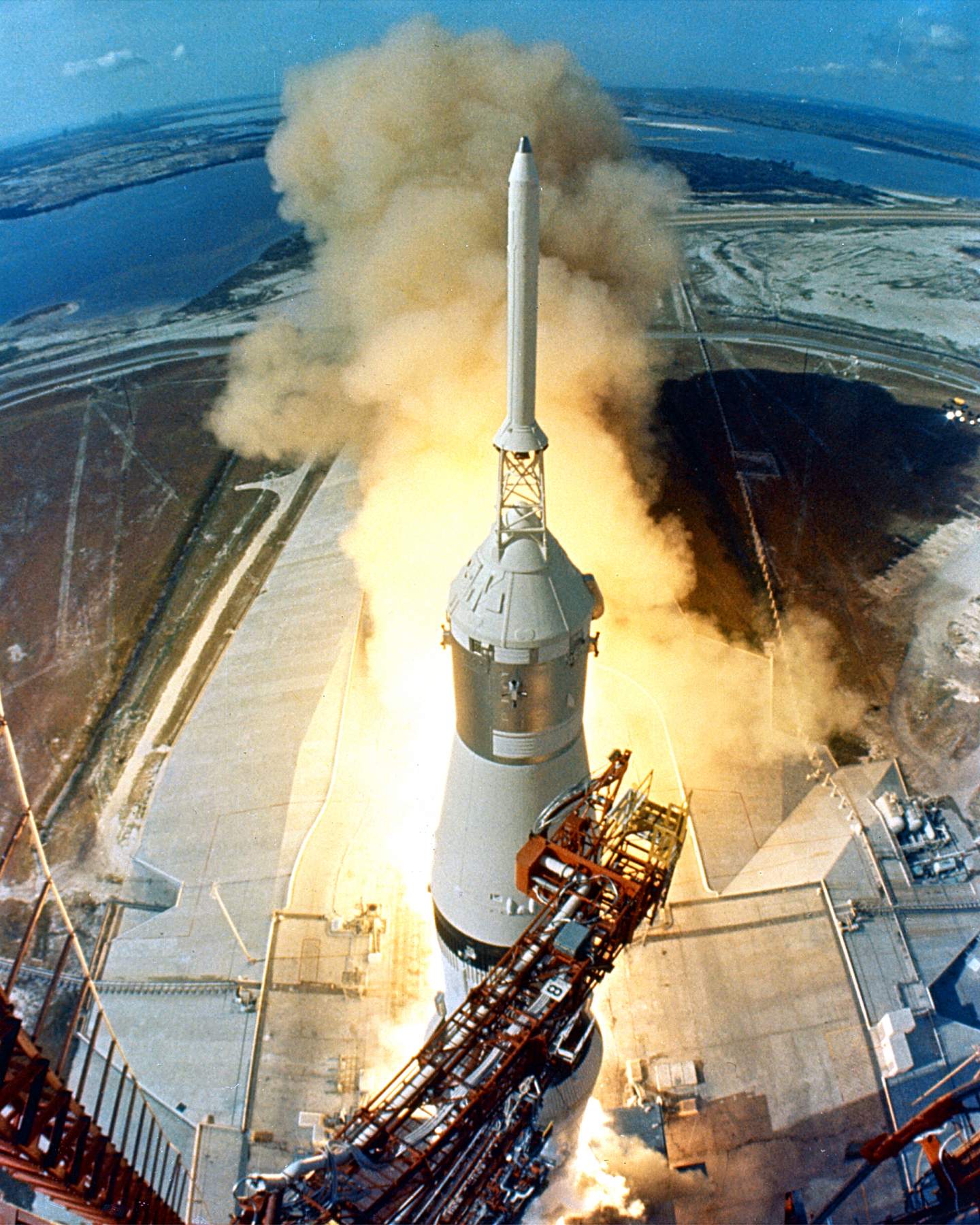

I do a lot of math, calculations and research to ascertain what I want to try. I study hard and think hard. Then, with an idea of where I’m going and wary of errant paths ruled out by the physics, I start testing and building. Only then I can figure out the answer. It helps to not have to test 10 or 20 ideas that (in theory) can’t work. I want to test plausible answers, not all answers. Like Wernher von Braun said, “One test launch is worth a thousand expert opinions.” Wernher (not a stupid guy) brought real potential to the launch pad, not imaginary concepts.

So I repeat: “All the math and science in the world won’t tell you what will work at the racetrack, but it will tell you what won’t.”

Thus, I spend a lot of time testing my bikes and designs. In recent months, I’ve done more riding on my klunker and gravel bike than my mountain bike. I’ve taken both of these bikes down that craggy turn filled chute on Mt. Tam and a lot of other rides. I’m looking for the bike’s limits. Where does it break down? What are its weak links? What has to change? What’s good enough (for now)?

I like to use test bracketing. This is something similar to exposure bracketing in photography or artillery calibration for a fire area. Logically, it’s most like a binary search algorithm or a bisection root finding method. Because it is so hard to establish what is or isn’t working well in a particular design when we are using it well centered on its given design mode, we instead use it in ways well to the edge of that. We push the use hard: taking a gravel bike on a downhill trail or racing it in a criterium-type situation. The bike wasn’t intended to be used in either of these places but by using it there, we can most clearly experience how its design breaks down.

As an example: using the Airspeeder as a mountain bike. It’s readily apparent when riding this bike hard off-road that the real weak links are the brakes and the tires. The riding position, gearing, even that it’s fully rigid aren’t big issues. The bike’s geometry feels very good and it’s composed. Climbing is very solid so the rear center could move 5 or 10 millimeters shorter to help the loft of the bike. The brakes are under-powered and they over-heat. The heating issue here is the use of road calipers instead of off-road calipers, a problem that will be solved when SRAM Level TLM ‘flat mount’ calipers are introduced to the consumer market. The underpowering issue is related to the lousy tires. Too much power and the tires will loose traction in the slippery dirt when the narrow, low knob, high pressure tires skip off. So I’ve increased the rotor diameter in the rear slightly (the worst offender and least dangerous to change), so that the rotors are 160f/160r instead of 160f/140r. That’s a help. Swapping out the 170mm RockShox Reverb seatpost for the 185mm BY Revive seatpost proved what a dramatic improvement a seatpost can make. Effortlessly smooth. The tires are the trickiest part of the puzzle. Their width is restricted by both the form given by the narrow road cranks and the designed use of the bike. It’s not intended to be a mountain bike. It’s intended to be somewhere between a mountain bike and a road bike. Dare I say: a hybrid. The tires really suck off-road. They really suck on pavement. Do they bridge between the two at the right bias? That’s what we look to be the greatest change on the bike.

Then we move to the other side of the bracket. I set the bike up with 30mm tires, a 42 tooth chainring, with both flat and drop bars. I do most of my pavement testing during my Marin to San Francisco bike commute where I can run flat sections of the Great Highway, steep climbs up Twin Peaks and in the Presidio, and gentle dirt sections through Golden Gate Park. I ride urban like the Boston skateboard hooligan that I once was, trying creative lines and cuts at speed and on pavement. Here is where we hit the wind wall. Is it more important to hide from the wind or to be in superior control of the bike? The flat bars are really better everywhere but in the wind. The narrow slick tires get a bit loose when railing downhill dirt sections in the park. The geometry feels good but could be a little steeper in the front to quicken it and reduce the wheel flop, possibly adding a degree or degree and a half to the head angle while keeping the bars and front wheel fixed. Generally, very good results that break down at the tire problem which is built into the design and purpose of the bike.

So, in testing this bike like this, we learn that the rear center can be reduced and the head angle steepened, we can buy improved calipers when they arrive, and keep testing tires. That’s a nice and concise assessment of the bike. It works great now. It can be made better the next time. Knowledge.

While I’m looking at this process to work on improved design, any rider can use this method to produce improved fit and position on a bike. A typical studio fit service helps place a rider in a position that helps when riding an indoor exercise bike. In a performance setting, we look to move the saddle and handlebars as forward as the rider’s physiology will allow for a given use. This improves climbing and sprinting – where the action takes place – out of the saddle. Since this position relies on the rider’s flexibility, core strength, arm strength, among other factors, we can’t arrive at them in a static position. We go out riding, swapping stems, sliding saddles, and changing spacers. Eventually, we find that point where we get something that is nice for general flat surface riding but also nice for climbing and sprinting. This process is all about testing and checking. The more notes and drawings that are produced the better.

Am I the world’s greatest test rider? No. I have pretty a realistic understanding of my skills and abilities on a bike. I kinda suck, but I’ve been riding aggressively for about 30 years. I’ve ridden mountain, road, cross, fixies, and bike commuted. I’ve been paid to ride my bike (as a bike messenger in Boston) for a year in 1990. I’m terrible at jumping. I can’t climb for shit. I’m pretty solid in roots and rocks. I’m willing to fight to not suck dust and to stay in a paceline. I will talk shit and fight for the front going down almost any hill. The key to all this is that while I am not the best in the world at riding my bike I’m still able to focus in on test variables and feel differences in how they work. Racers are rarely good test riders. Going fast and understanding how are different things. Better…is usually better regardless of skill level. I also have enough knowledge of what others on doing on bikes that I can infer a bit as well. Certainly, I know that I don’t have to worry about what total outliers like Sam Hill are using for something to be true for the other 99% of riders.

Big companies can buy the best talent available to ride their bikes. They can buy world champion racers. They can keep a support staff on hand to make changes. Still, their end goal is always to sell more bikes and building the most fun or fastest bike isn’t really the goal. My difference is that I’m not trying to sell bikes. I’m trying to make the best bikes I can. So, I ride stupid bikes down scary trails. Bikes that really aren’t intended to be used this way. What do I learn? I learn about limits. I see what can becomes a big problem quick. Can the bike be loaded onto a bus? How is it the stretch of Great Highway with a headwind? Can it handle this next drop?

We learn unexpected things testing. We discover things that are working better and details that are suddenly important.

Why is any of this important? For a guy like me who has spent all of my life trying to figure out ways of making better mousetraps, the answer is obvious: we want better. We want to go faster, higher, longer. We want to feel better, smile more, get more thrills. When we test well, we discover or prove the ways to deliberately get there. We improve how well we can predict the results of changes we make. Most people are content with copying the work of others, hoping it works, and giving it a fancy paint job. That’s about 90% of the builders out there. Others, like me, are trying to get from here to there. Real testing is the way we know we are on the road.

Testing doesn’t always go well. Sometimes you learn that you aren’t as smart as you think you are. Other times, you push things past the reasonable. This weekend I was testing the Airspeeder at China Camp. Of course, I wanted to see just how fast I could ride the hard line at the bottom of Hitler. It was as dry and slippery as it can be at the height of summer. I was doing well enough considering the bike I was on. Then, right near the bottom, when I thought that the worst was behind me, the tire shot out and I was pummeled into the ground. I broke my left control for the dropper….and possibly my right thumb. Not sure yet, could be a tendon. I’m really not happy with the Wolftooth lever mounting or it’s breakaway feature. Another lever would have survived this crash for sure.

We don’t know where the line really is until we cross it. I found out. I tested it.

Part of building better carbon rims is making evil destruction machines. This drop tester in New York measures rim strength and radial compliance, like the 10mm deflection you see here, but it can also measure how well a given rim shape prevents tire pinch flats and other tire damage. There's no such thing as too much testing.https://www.notubes.com/news/cb7-riact/?utm_source=CB7-RiACT-Blogpost-Social&utm_content=CB7-RiACT-Blogpost-Social

Posted by Stans NoTubes on Wednesday, March 28, 2018