Let’s look at the buffer for my new AR-15.

It’s key to understand the gas system of the rifle when talking about the buffer. The gas system of the AR-15 is dependent on several variables for proper function. A bullet is fired, powder is transformed rapidly from a solid to a gas. A massive pressure is created between the spent case and the back of the bullet. These pressures increase as the powder burns and the bullet passes through the barrel. If the powder, charge, barrel, and bullet are well suited, the bullet will continue to accelerate until it leaves the muzzle at the maximum possible velocity. As the bullet passes the gas port and gas at some pressure is allowed to pass through the port. The net pressure during the ‘dwell time’ (time between gas port and muzzle) and port diameter provide energy to charge the BCG (bolt carrier group) piston to unlock the bolt and push the BCG back in it’s track. The energy going into the BCG need only be sufficient to slide it’s mass and buffer mass back slightly past the open bolt lock while resisting the buffer spring tension. Now, the BCG and buffer can begin moving forward to the breach. The stored energy needs to be enough to overcome friction, load another round into the breach, and lock the bolt closed. Obviously, a lot of factors that produce a properly gassed rifle.

Too small a port and the buffer needs to be lighter, too large a port and the buffer needs to be heavier. Too short of a dwell time and the port size needs to increase. A light BCG and the buffer needs to be heavier or the gas needs chocking.

My barrel has got a 16″ barrel. Mid-length drilling with 0.082″ gas port on a 0.750″ lug, standard carbine spring (11.75″) and buffer.

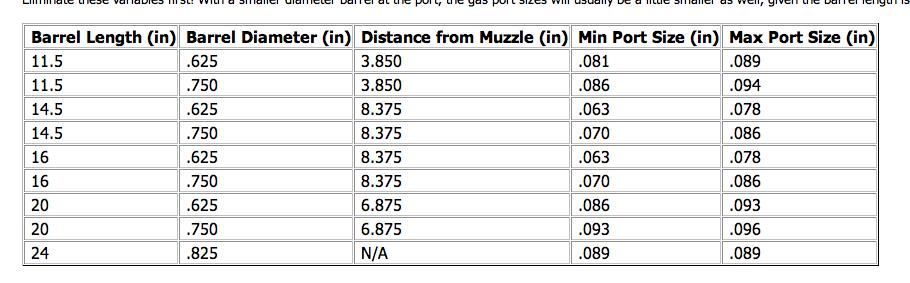

This chart I found online seems like a well sorted guide for the port sizes given the several variables. It is very difficult to find proper details.

My gas port falls right in the 0.70-0.086″ range for the barrel but on the higher side.

A rule of thumb is to use the heaviest buffer that will still lock the bolt back after the last round is fired from the magazine. This can be turned around with an adjustable gas block, trimming the port down until the bolt just locks.

I’m going to play with buffer mass rather than an adjustable gas block.

Consistent values for the weights of buffers are hard to find. Sources vary. Mil-spec isn’t available.

STD CAR: 2.96 oz.

H1: 3.9 oz.

H2: 4.67 oz.

H3: 5.4 oz.

Rifle: 5.18 oz.

DPMS 308/AR-10/SR-25 Rifle: 5.41 oz.

DPMS 308 CAR (short buffer): 3.80 oz.

AR-10/SR-25 CAR:

9mm: 5.6 oz.

45 Cal: 7 oz.

I’ve been told that the designed weight of the 3 types of buffer weight materials are as follows, but I’m looking for real confirmation:

- Aluminum weight: 6.33g (0.223 oz)

- Steel weight: 18.49g (0.652 oz)

- Tungsten weight: 41.74g (1.473 oz)

I had a standard buffer from a CAR in hand. The cheapest of buffers due to lack of tungsten weights.

Generic CAR:

3x Steel weights: ∅ 0.544″, L 0.613″ Weight 18.1 g. ea.

3x Rubber discs: ∅ 0.525″, 0.072″ thick Weight 0.3 g. ea.

1x Roll pin: ∅ 0.125″x 11/16″ Weight 0.7 g. ea.

1x Plastic bumper: Weight 4.6 g. ea.

1x Buffer case: Weight 23.2 g. ea.

Total: 83.7 g. (2.95 oz.)

Sourcing tungsten weights is not easy. They can be expensive and may not be the correct size. The best I’ve found was from KAK @ $6.35 each. Other sources get up to $16 each.

KAK Tungsten weights:

∅ 0.555″, L 0.600″ Weight 42.5 g. ea.

KAK Industries Tungsten Weight

I put a custom buffer together from what I had.

PVD H2 CAR:

2x KAK Tungsten weights: ∅ 0.555″, L 0.600″ Weight 42.5 g. ea.

1x Steel weights: ∅ 0.544″, L 0.613″ Weight 18.1 g. ea.

3x Rubber discs: ∅ 0.525″, 0.072″ thick Weight 0.3 g. ea.

1x Roll pin: ∅ 0.125″x 11/16″ Weight 0.7 g. ea.

1x Plastic bumper: Weight 4.6 g. ea.

1x Buffer case: Weight 23.2 g. ea.

Total: 132.5 g. (4.67 oz.)

I’ll put together an H1 or H3 buffer to have on hand for next time I shoot so I can swap out until I find just the right mix.

There are lot’s of people online that advise to use weights for pinewood derby cars and tungsten powder. Derby car weights are 3/8″ diameter thus unsuitable for use. Powders may work but they do change how the dead blow functions in the buffer.

One cool thing that I found while looking for tungsten weights was a supplier of weights for balancing crankshafts. Although they don’t come in the right diameter, they are really cool to know about. ABS Products has an amazing selection of tungsten weights at decent prices. MiTech Metals has a less expansive selection but slightly cheaper prices. Definitely where I’m going the next time I need ballast.