Better. Stronger. Faster.

I had two heroes when I was very young child. Mohamed Ali and Steve Austin. Ali was amazing. Steve ‘was’ an astronaut and more.

It’s been quite a while since I’ve been able to put serious development time into the all-road platform. It was mid-2021 when the majority of the work on the 2021 PVD TIE Advanced X1 was completed. Even at the start of that assembly the TIE, I felt like there was a lot more bike left on the table that hadn’t gotten into the final product. I’ve been riding that bike since and thinking of what it is missing and where it needed to go. I’ve been waiting patiently for the chance to do an update. I’m not whining, I got to ride an amazing (far nicer than anyone I know) bike for the last two years.

Special about the TIE is that it was the first of my bikes to use additive metal construction. Significant learning and methods have developed in those two years as several generations of mountain bikes have been produced. I know more now. Not just in what could be needed for a bike but in how solid modeling changes can improve the shape of the prints and bike. Solutions that were previously extremely difficult have become quite deployable. Taking all of this to the new all-road bike was going to really be a change in how this platform presents.

The namesake for this bike, the Northrop M2-F2 was a special development ‘lifting body‘ and was part of NASA’s Hypersonic Research Program. This for flight through an atmosphere at speeds in excess of Mach 5 with tests conducted in the 1960s. These test laid the groundwork for what became the NASA space shuttle program.

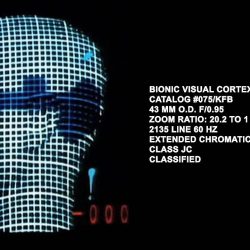

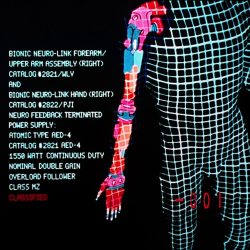

The 16th and final test flight of the M2-F2 crashed (1967) with the pilot, Bruce Peterson, surviving but suffering significant injury. This crash and Petersons injuries were used in the intro for the movie and television program (1973), The Six Million Dollar Man. That movie and show was based on the 1972 novel Cyborg.

In those, Steve Austin, is the pilot and in that crash. He is saved (and cursed) by making him the ‘worlds first bionic man’. It was compelling stuff in the early 1970s. It was pretty awesome stuff and kept the imagination at work. This was all a huge influence on my childhood. It’s now becoming more of a reality.

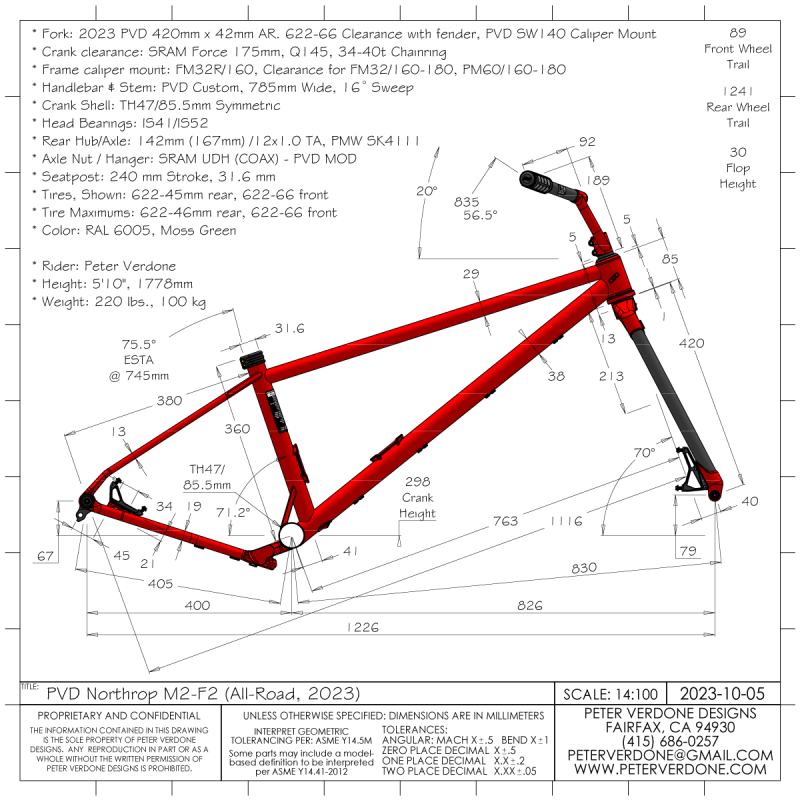

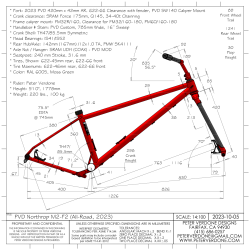

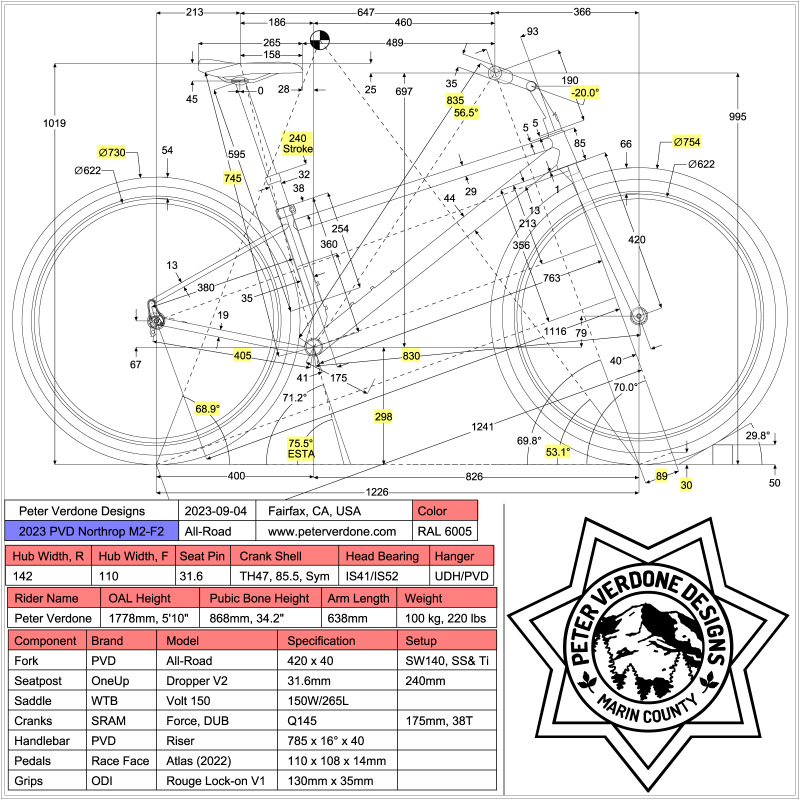

Now, I’m reworking the all-road platform. I had a few goals to build from the TIE right from the outset:

- Reduce flop by steepening head angle and decreasing fork offset keeping FWT similar

- Increase front center significantly

- Shorten the rear center

- Lower the top tube

- Steepen the effective seat tube angle very slightly

- Very slightly more upright riding position.

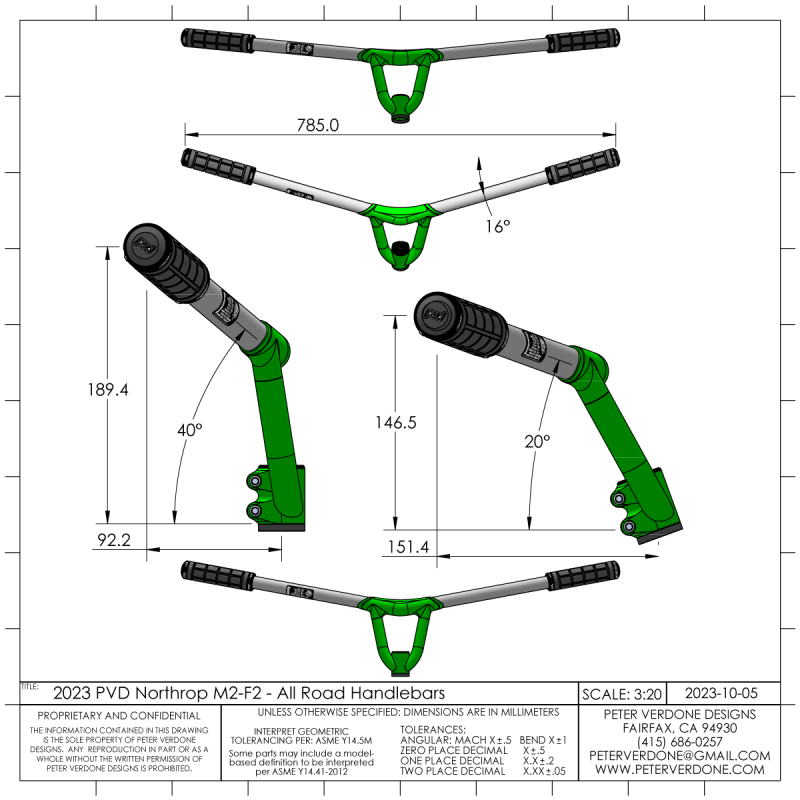

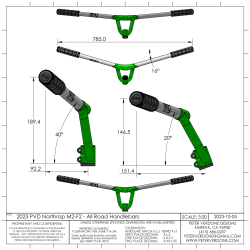

- Increase bar sweep from 14 degrees to 16 degrees.

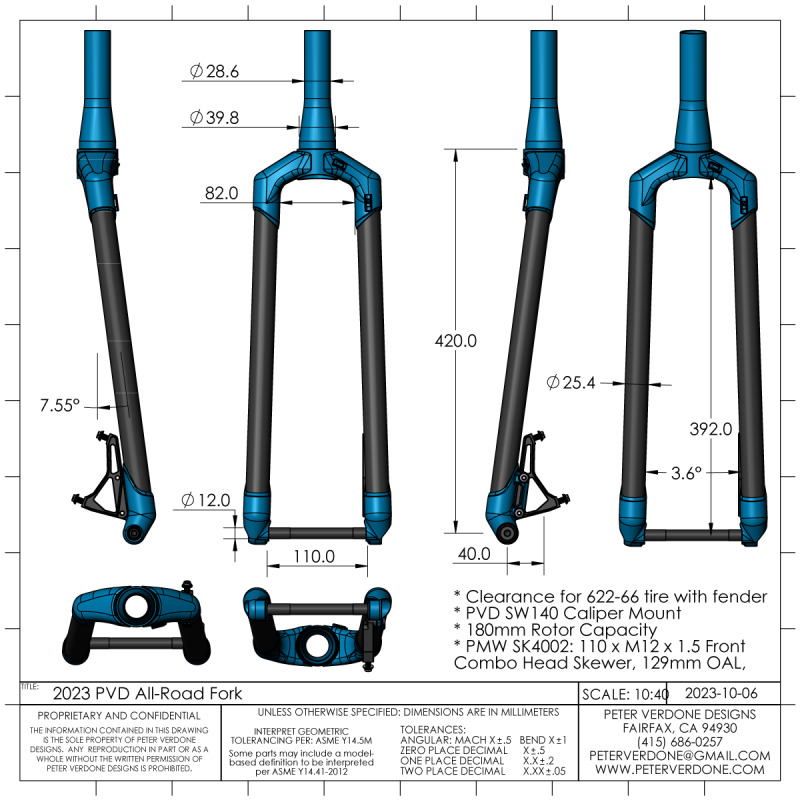

- Improve fender clearance for the fork

- Increase tire clearance in the rear.

- Improve rigidity of brake caliper mounting

- Improve heel clearance at the dropouts and stays for use with flat pedals.

- Modernize prints and methods from previous two years of development

A few special developments were needed for this build:

- A new crank spider that would work with SRAM 8-bolt cranks and hold the ring with full stay clearance.

- Another try at additive handlebar weldments.

- A new stem facing arbor for axis interrupting bars.

- A new water bottle/bag strap braze-on that would improve carrying and modular components like pumps while de-cluttering the frame.

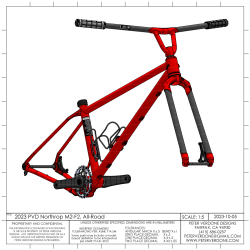

- Titanium spec for fork blades

There are many reasons why I like the all-road bike. It’s lean and mean. It simply covers ground fast. Wherever you want to get to, you can on the all-road bike. It feels good beneath you. Your knees are happy. If you see a trail, you can take it. If you have to ride on pavement, it’s not so bad. I just like getting on one and discovering where I want to go. That’s the magic. Just go. Figure it out on the way.

An issue that I struggled with in the defining of the geometry was dealing with the discrepancy in tire sizes. While I’ve been doing this for a while, I wondered if a base geometry should be constructed with more consistent tires of a specific size and deviations shown as an auxiliary geometry. I ended up just keeping the current system but I am thinking about if that was correct or not.

The low flop geometry has come to this design. 30mm of flop with 89mm of front wheel trail. This produced the steepest head angles of any bike I’ve done in years at 70 degrees. Every time I go steeper, bikes get better. Few are talking about this.

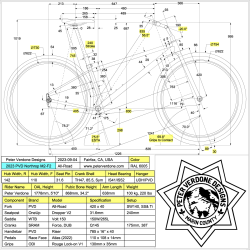

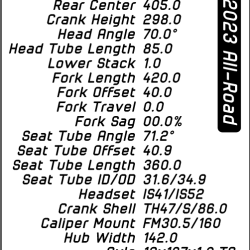

The setup print for the whole bike. Those are some sweet front end numbers! I’m still working on this ‘Instagram’ template and what’s being shown. I think it does a pretty good job communicating the intentions of the bike straight from BikeCAD.

The new bottle cage/strap/aux mounts are pretty cool. Notice that no holes were needed to be cut in the down tube, keeping it very strong. I was worried that they would look like clutter on the frame but once everything is strapped in place, it look like normal…just with more options. The pump is super solid even without a security tie. The large waterproof cylinder is a test of another concept for tool stash.

Of course, one of the features that puts this bike right into the middle of the all-road category are the Q145 SRAM Force (00.6118.661.004, FC-FRC-ASSY-D2) 175mm cranks. This narrow profile makes pedaling especially over long periods of time feel so much nicer than a wider position. To accomplish this, a custom spider was (again) needed. This gives me a 49mm chainline with any 110mm BCD chainring. Not an easy task with anything higher than 36t. The spider also designed to be set up with an even narrower chainline as the frame allows. The bike is shown with a 40t chainring, the max that the frame is designed to accommodate, again, all-road gearing.

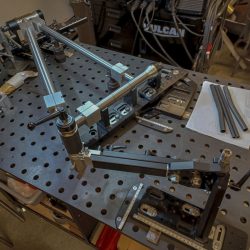

This was my first chance to use my new tooling while constructing this frame. It was just another level of seeing the locations of tubes in the rear end. Learning some of the tricks to it took some time but it’s a big advance.

The color for this bike is RAL 6005, Moss Green. It’s getting onto the darker side of green and the hope was that it would look cool against the titanium fork blades and handlebar ends. I was also interested in something that was a little less flashy for poaching. Don’t miss the previous post that describes a disaster that took place at the powder coating!

The rear of the bike got a FM160-30.5 caliper mount. Stoked on the cool new adapters for that. I stayed with the PVD SW140 caliper mounting for the fork. I had adapters on hand and it’s what the situation called for. If I do more of this I would like to develop the system more.

I would loved to have less of a squared off arch inside the crown of the fork but it was needed to help the big winter fender to fit. I really need to start doing some custom carbon fiber fenders so that I can have more control of this shape in the future.

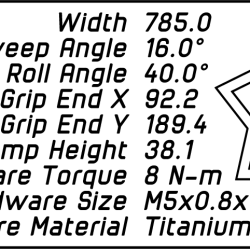

The cool 16 degree sweep high rise bars get’s the riding position just to the comfortable side of aggressive for the use case described. Cover ground. Cover it quick. Ride sick trail.

I’m trying the Maxxis Pace 622-53 tire in the rear, hoping to get a little more roll than I was from the Maxxis Crossmark II 622-53. I may move up to a 622-57 tire after this. We’ll see what the mood strikes. Wet winter riding may push me back to the Crossmark.

The wheels were fitted with Cushcore XC inserts front and rear. In actual off road environments, this makes a big difference. They also do a bit to support the very thin light tires, giving them the handling performance feel of a heavier tire. This seems to be a good mix.

Ride #1 – 2023/10/07 – Tamo to Pine Mountain to Lake Lagunitas.

HOT! A nice little test loop with singletrack, fire road, and pavement. It was surprising how well the bike felt on the pavement descent to the golf course, even with the tires as shown. This thing screams.

I ended up adding 2mm under the stem. Old man stuff. This makes up for the material that was trimmed on the lathe from the ‘as supplied’ PMW binder. Basically, bringing the bars back to blueprint.

I was wondering if the titanium fork blades were stiffer than the carbon blades on the TIE. They seem very similar just pushing the bike against the brakes but I couldn’t tell if as much was being absorbed on the trial. I need to do a proper test of the two. Still, the fork was fine during the ride and it was just a couple of spiky hits that had me thinking.

The Maxxis Pace tire seemed to fit the mode of the bike nicely. It definitely rolled nicer than the CrossMark. It seemed like the traction was fine in todays dry conditions.

Ride #2 – 2023-10-08 – Deer Park, Eldridge, Northside, 999esses, Junction.

Hot again but not as bad. What was bad was me. I felt like crap. Unmotivated, exhausted, shitty.

A funny thing happened, while resting near the top of 999esses, I hear a rider coming down the rock garden. Odd for such a place. I wait, getting ready to give the rider shit. Turns out to be Matt McKibben on some epic ebike poach. It was hilarious.

I really do think that the fork is stiffer than before. Going to test for sure. I’m going to look at what diameters and wall thicknesses will give me the flex and durability that I’m looking for.

The bike worked great. Most of the ride I was just looking at parts that needed some re-shaping but otherwise the mechanics were perfect.

Ride #3 – 2023-10-10 – Fern’s Gravel Goon Ride, Deer Park, Eldridge, down Rock Springs FR.

Your basic group ride. Climb to the top and bomb down. Aside from just more saddle time and feeling the bike out on the climb, I was able to do a hot run down a very fast fire road. This was important as I got to feel the front end in a specific and important condition. The bike handled with ease and confidence. It’s just so comfortable and easy even when running close to crash conditions. I’ll give it an A+.

The stiffer fork actually felt very good going down the fast fire road. This is a condition that would make a floppy fork feel very bad. The fork felt utterly composed and predictable. I just felt so good with this entire front end.

At the top of the hill, I got on one of the other folks bikes. It was a fairly common type of gravel bike and was approximately my size, 56cm. Even on pavement that bike felt terrifying and sketchy. I wouldn’t want to ride a thing like this on the road, forget about in the dirt. These experiences really back up my own impressions of my work. I’m convinced that I’m working in the right direction.