Warning! Some of the information below has been superseded by new information.

I’ve been doing a ton of work with disc brake standards lately. For my own new bike and because recent proposed “standards” needed correction.

This post is intended to pass on what I’ve come up with and communicate to the industry a path that can get us through a difficult time.

I needed to do this now, and I’m actually rushing, to get good information out to the market and industry before a flood of new and bad specifications emerge for FM160 and FM180. Hopefully, I can get some help spreading this information (or correcting it) from higher level industry folks. At the very least, I’m hoping to ensure that the small tooling, frame parts, and framebuilders make parts that work with what has been rolled out.

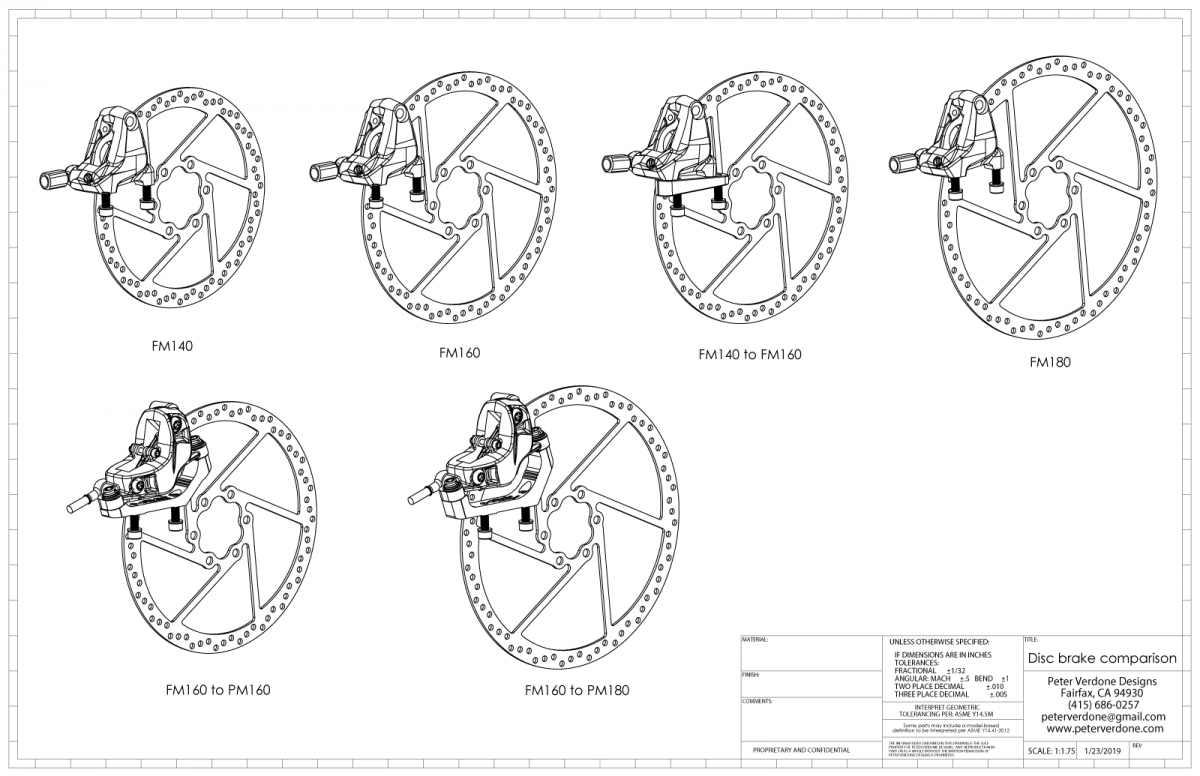

There are many ways to mount a caliper to a chassis. Sadly, we can’t just use a radial type caliper configuration as is used on high performance motorsport as the weight and structure of such a mount is out of line with the bicycle’s parameters. It’s a shame. Radially mounted calipers are one of the simplest ways of mounting calipers and the easiest to fit to changing rotor diameters. Instead, we use a few other systems depending on the situation.

Below, find published specifications from manufacturers and new (improved) specifications for Post Mount, Flat Mount, and International Standard mounting of calipers for the front and rear of a bicycle.

One important, and obvious, fact in all this is that the 203mm rotor needs to be abandoned in favor of the 200mm rotor and IS160/PM200 adapters be generated. This small change will allow so much more to be done with these systems.

We are all in this together and we will all benefit from bikes designed as well as possible. I can’t push this change ahead alone in any meaningful way but maybe others will see here why this move can be so valuable…and possible.

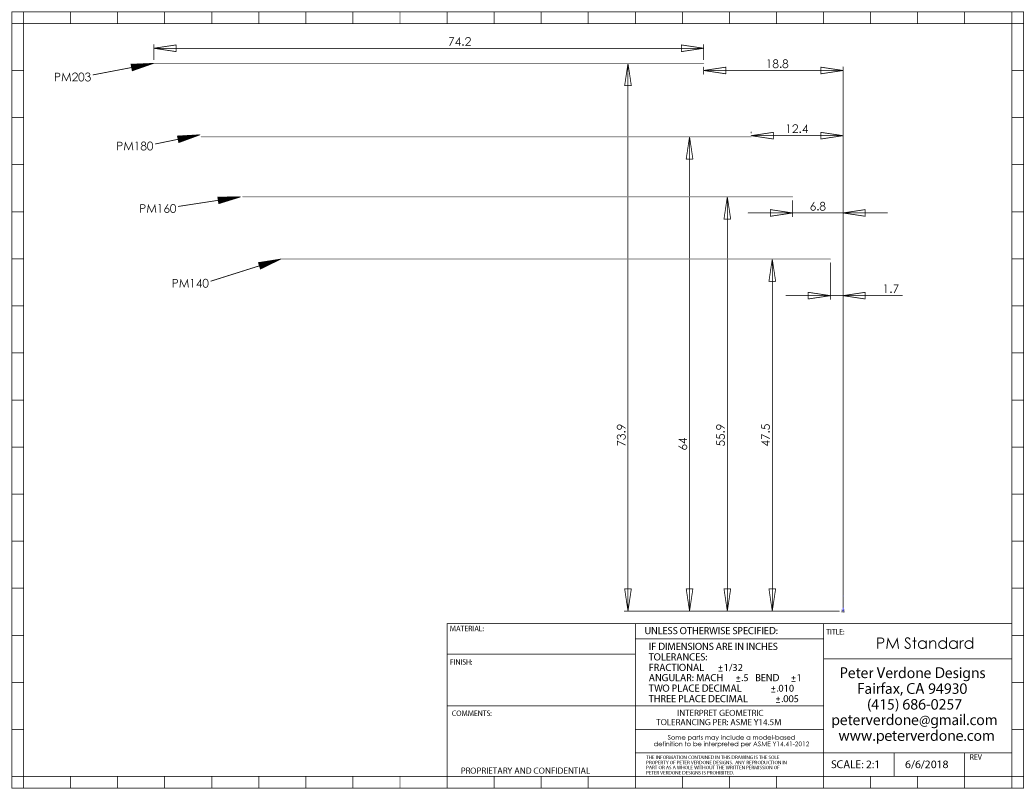

Post Mount:

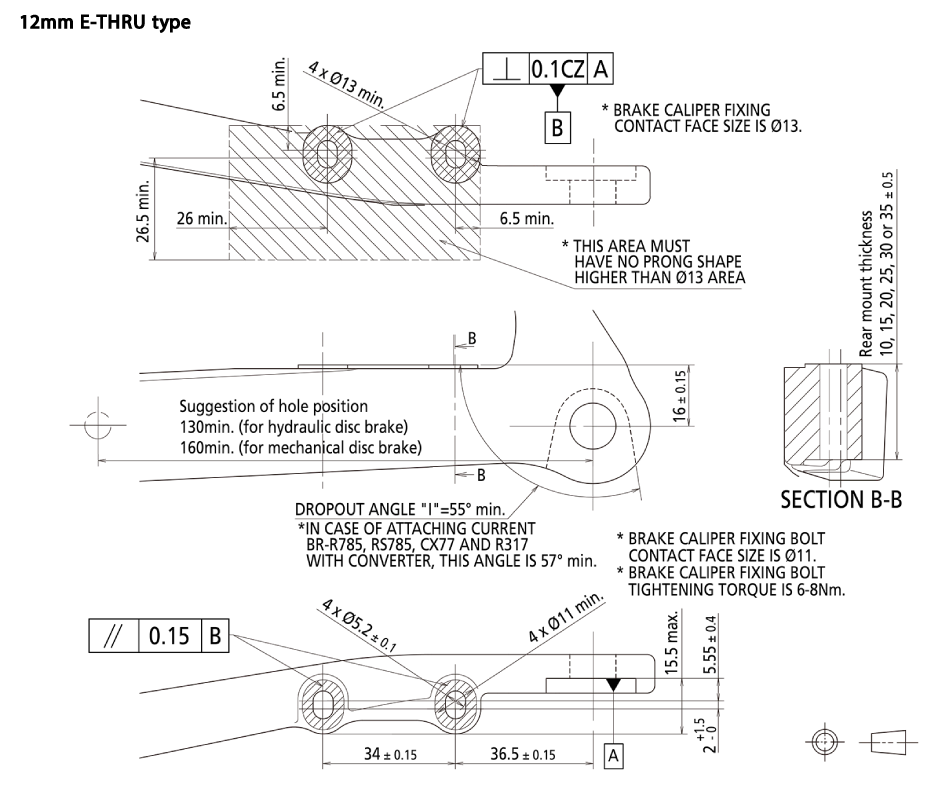

The Shimano Specification, as published:

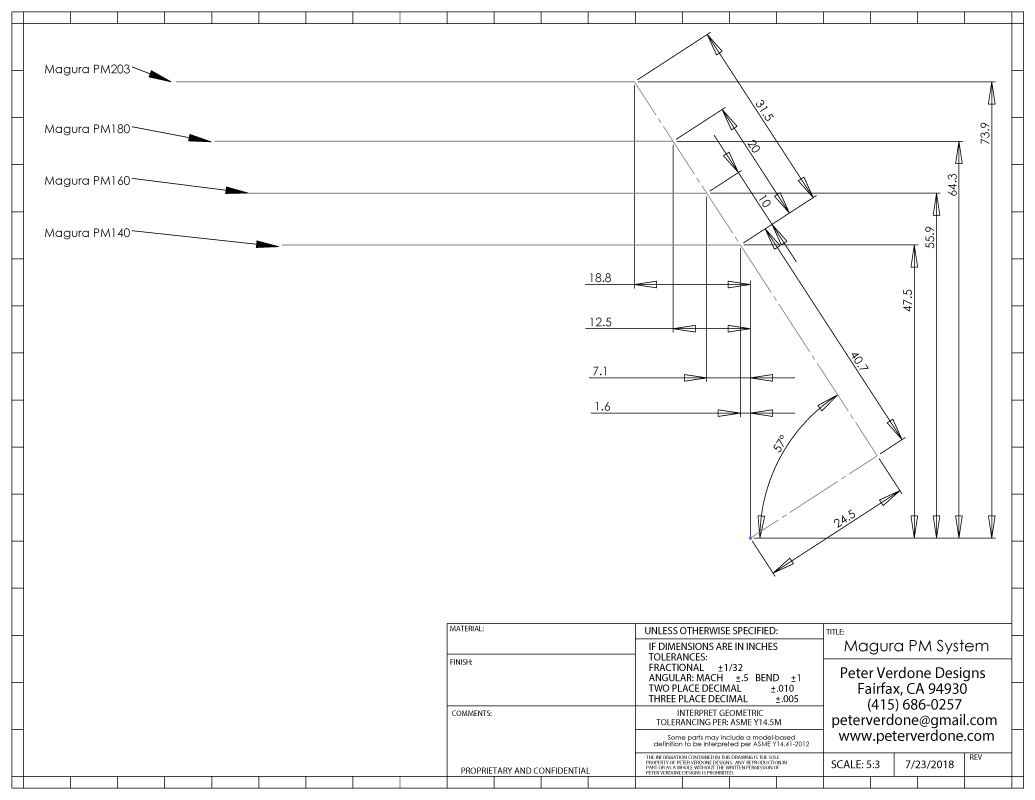

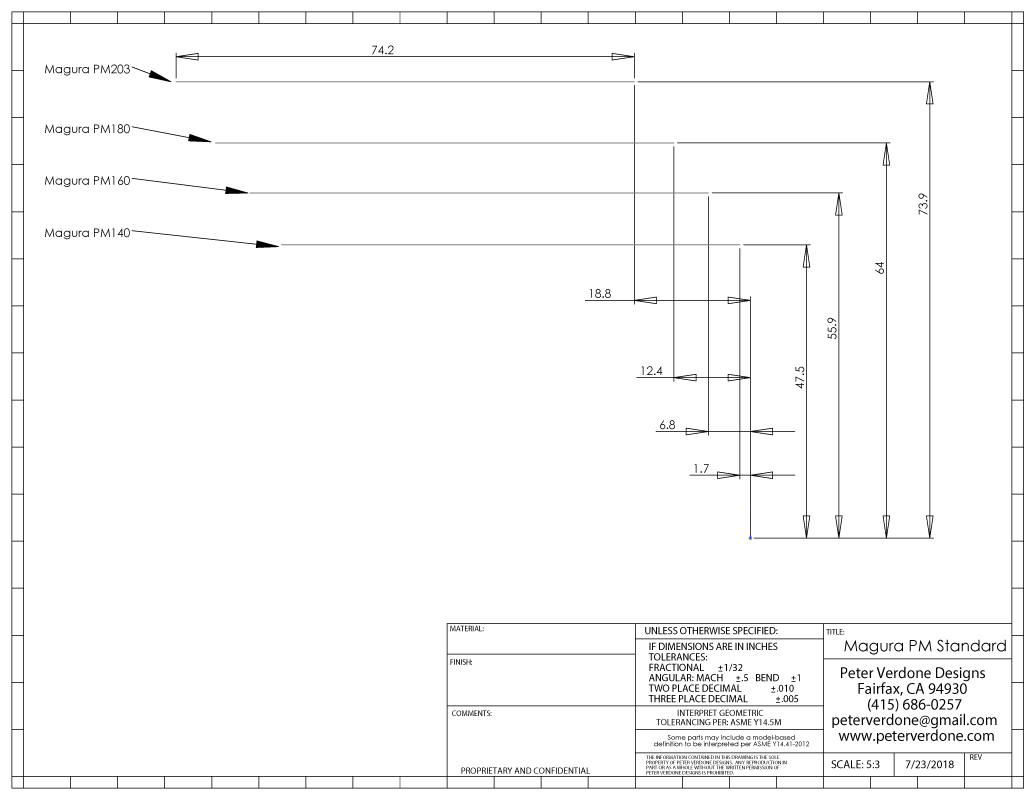

The Magura specification, as published: Remarkably close to the Shimano numbers.

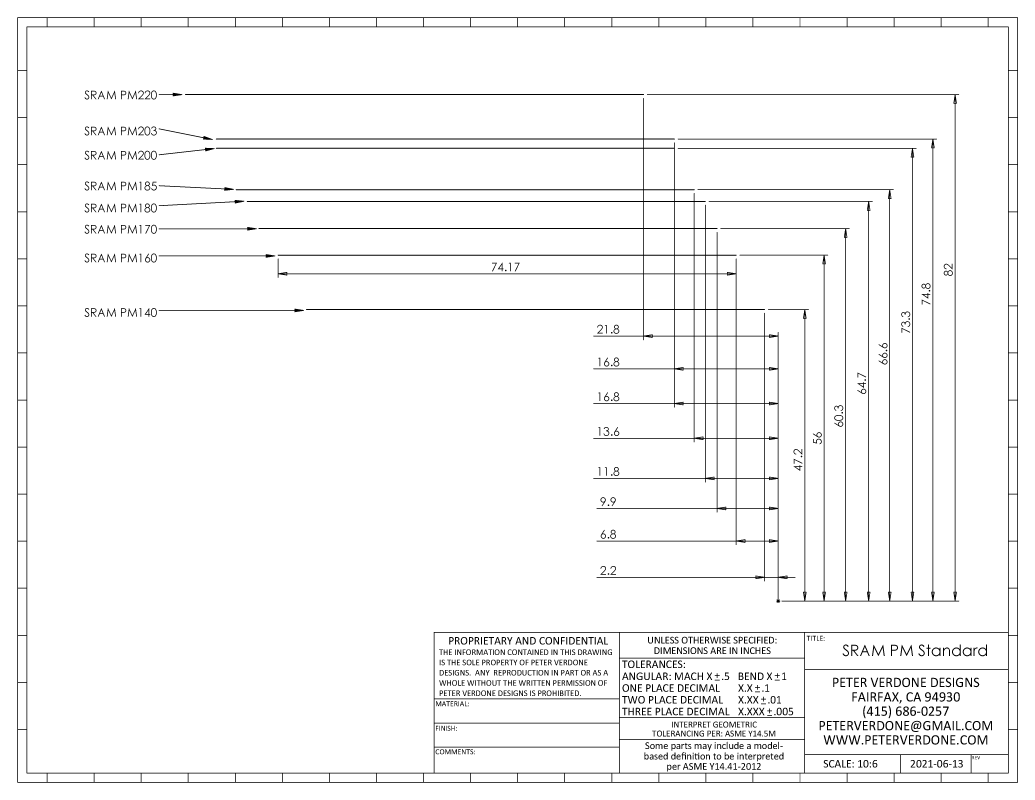

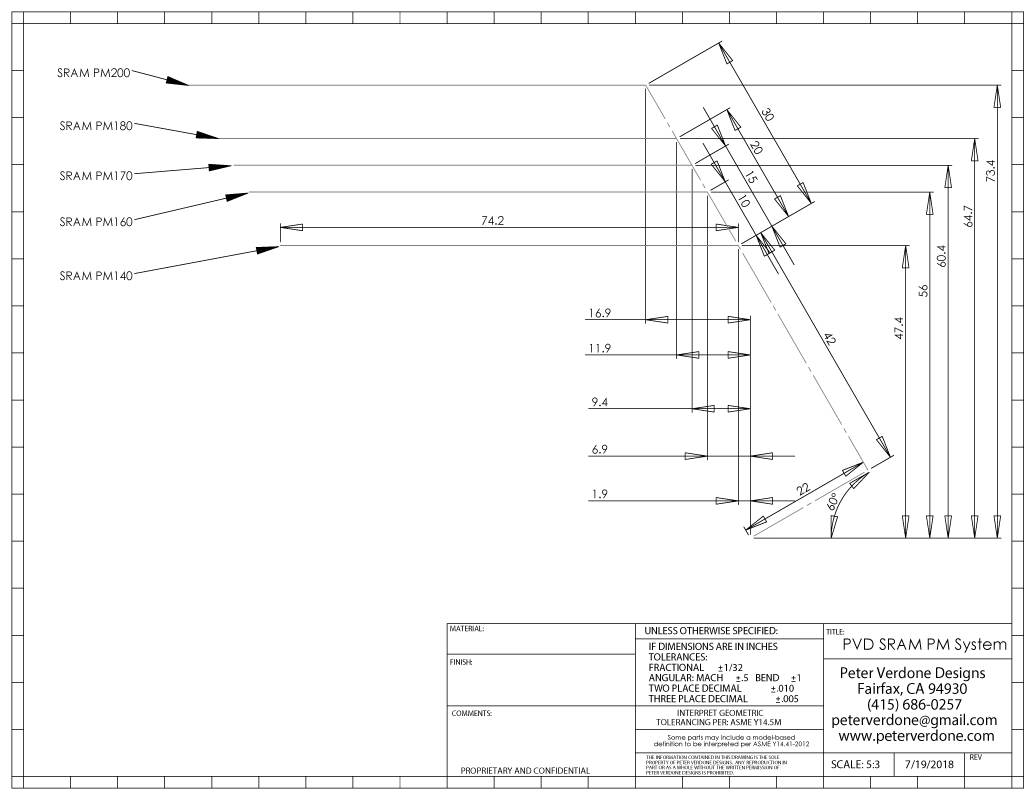

The SRAM specification, as published (2021): A bit different and more rotor sizes than Shimano provides.

Using these published numbers, a fairly accurate systematization can be arrived at that make engineering sense. By systematizing them, they can be more easily interchanged among different caliper and adapter types, offering the end user the most options and the builder far more options than previously specified. The radial distance from one location to another reflecting the difference in rotor diameter. The mount angle and axis offset can be consistent for each location. Attention was paid to the original intent of these systems, where they broke down, and rebuilding them to work for the future and custom configurations while not destroying the past. Many of the dimensions here are very close to (but not equal) those specified by OEM.

There is often a larger deviation from the official PM160 specification in the systematization. Further investigation will reveal that the PM160 specification has been the big problem for any brake standards moving forward since Manitou came up with it years ago. This problem should have been fixed 20 years ago as Manitou or the initial specification are now largely irrelevant.

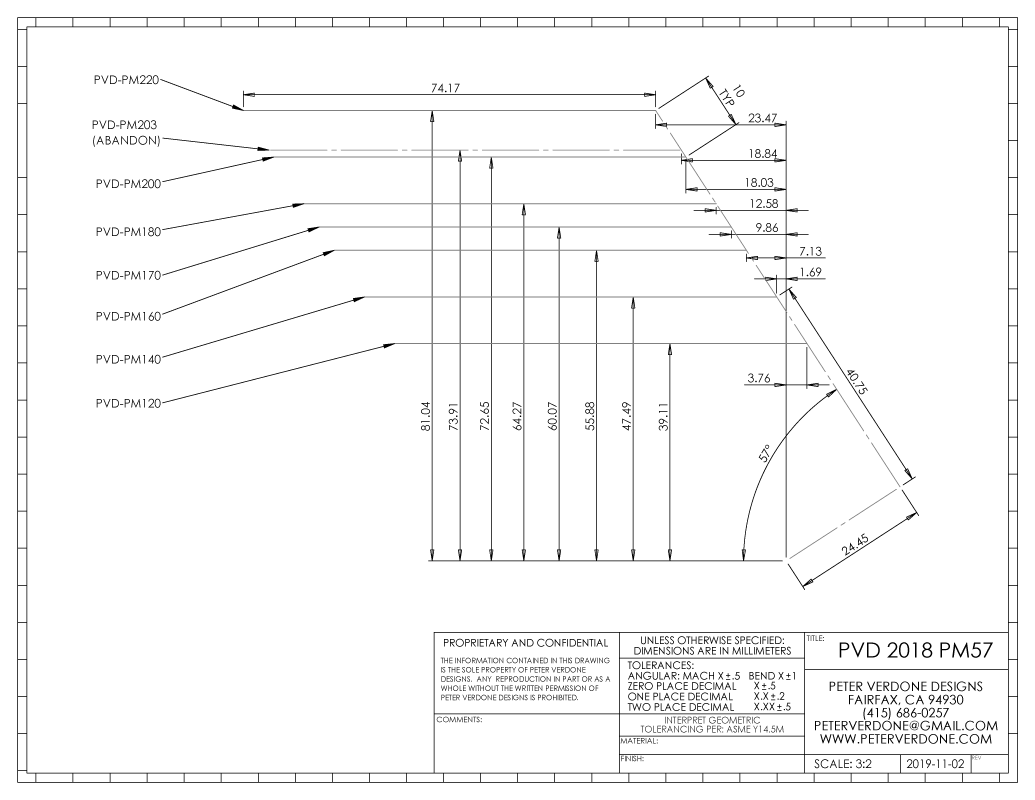

The system I devise here are based on the Shimano specifications as most of the industry will eventually reference Shimano for frame fit. The basis of this systematization is the 57 degree path and 24.5 & 40.8 mm offset, and radii of the rotors built over the Shimano definition. This is formed by the 140, 180, and 203mm positions (the 160 slightly off and needing of correction). From there, each system interconnects to the flat mount by way of adapter angles. It’s remarkably simple and has been applied by both Shimano and TRP consistently and Magura roughly.

Comparing the locations, you can see that the maximum deviation of my proposal from the Shimano published defined position is about 1/3 of a millimeter. It’s not really much and shouldn’t cause much issue as the industry has been using this as a system even though it isn’t defined that way, causing increased misalignment to already compromised pad positioning. I fix that shift.

The Shimano specification, PVD Systemization: Note the 57 degree and 24.5 & 40.8 mm offsets. This is the master system that we build the others around.

The Magura specification, PVD Systemization: Note the 57 degree and 24.5 & 40.7 mm offsets, almost exactly how Shimano systematizes. We don’t use this version.

I systematize the SRAM system below. The offsets of the system are off from Shimano system; kicked up three additional degrees from 57 to 60. This, I believe, as SRAM has based more closely around a system that matches the Manitou 160mm position.

The SRAM specification, PVD Systemization; Note the 60 degree and 22 & 42 mm offsets. The SRAM numbers can be ignored (This comment revised later).

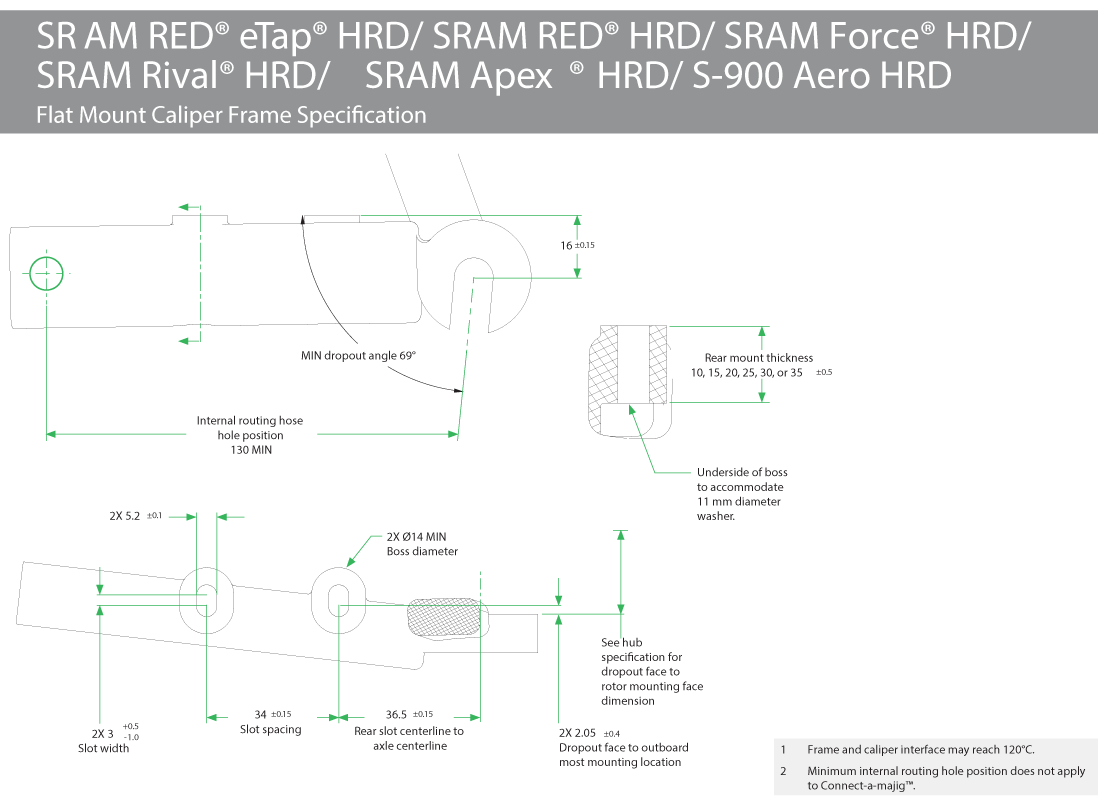

Flat Mount:

Flat mount is the flavor of the week and getting all the attention. Because the pad angles of post mount are steeper than it’s sizing scheme represents and the pad angle of flat mount is shallower than the translation angle produces, not much correction is possible to make up for pad twist at extremes. This is something for caliper manufacturers to address at a later date.

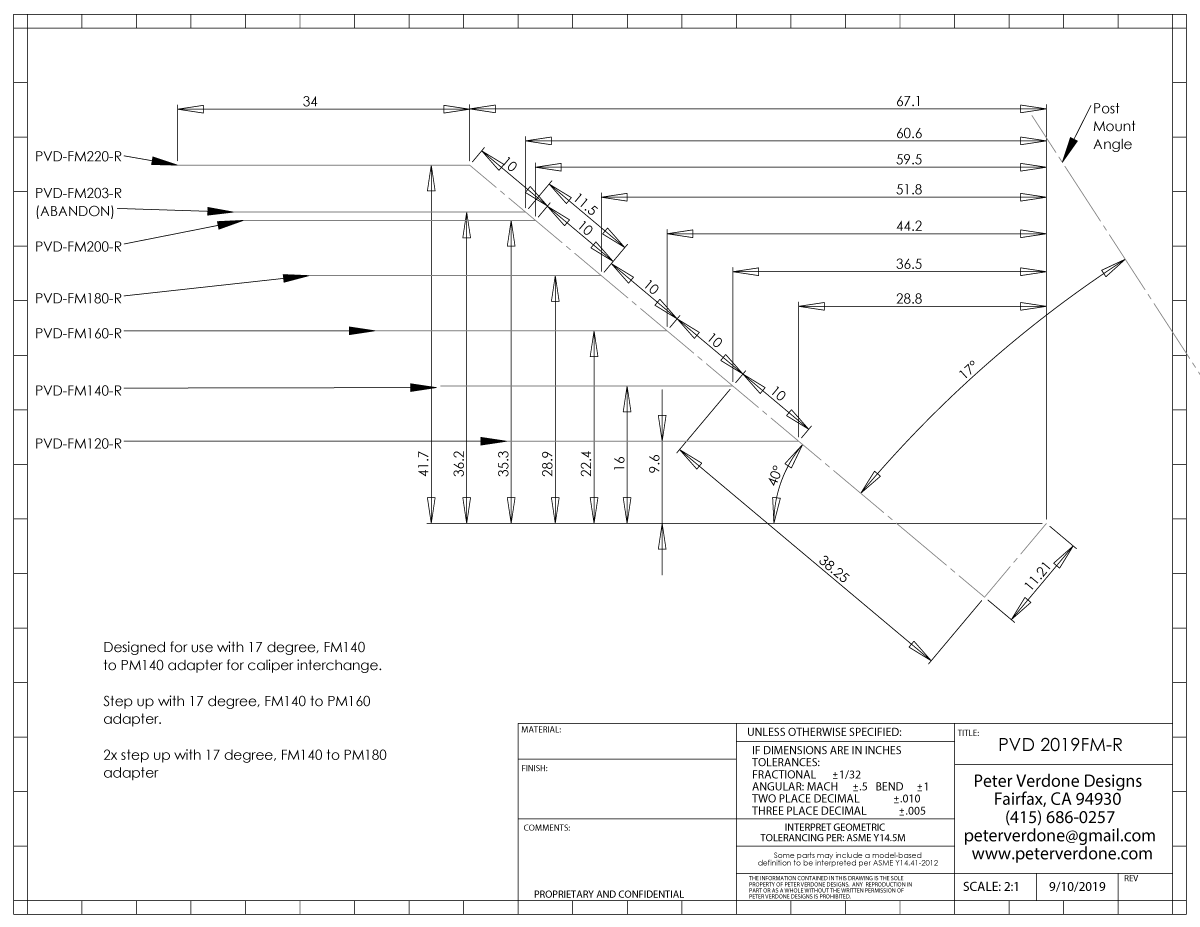

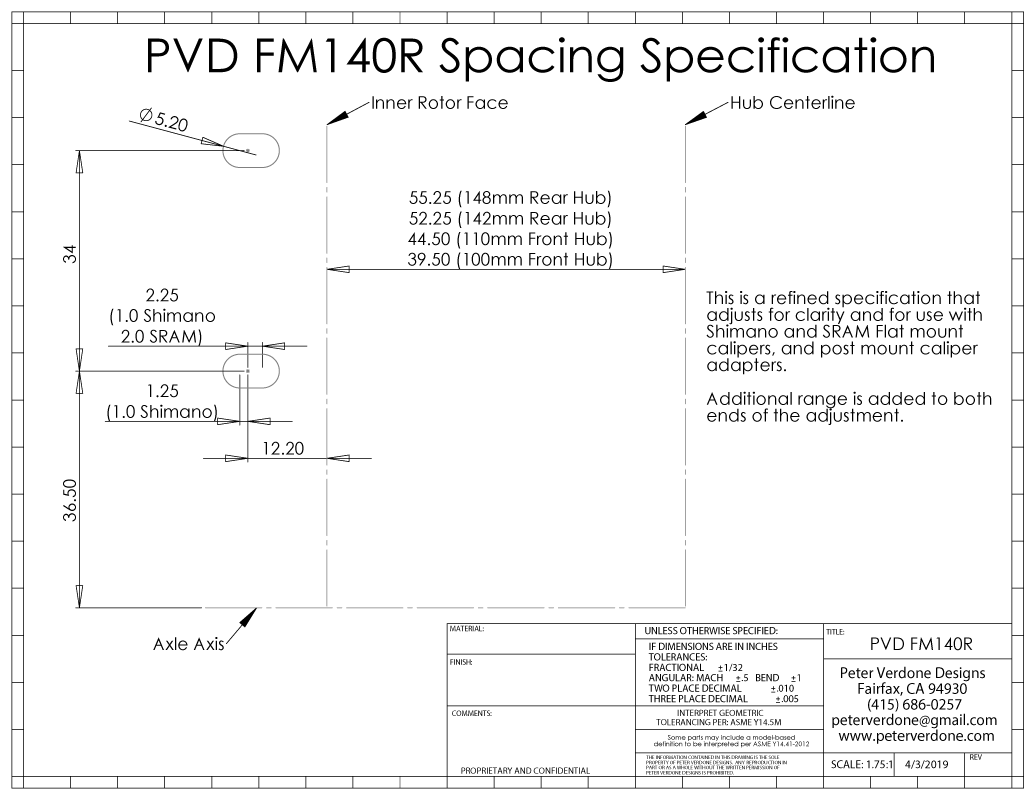

Both Shimano and TRP follow the 17 degree system for their adapters from FM140 frame to PM140, PM160, and PM180. SRAM doesn’t have adapters from flat mount to post mount so we’ll use the PVD Shimano PM System for the transfer. Thus, Flat Mount system must (at this time) connect to Post Mount by a 17 degree translation. It sits at 40 degrees.

The Flat Mount Rear system at 40 degrees with 17 degree translation from Post Mount:

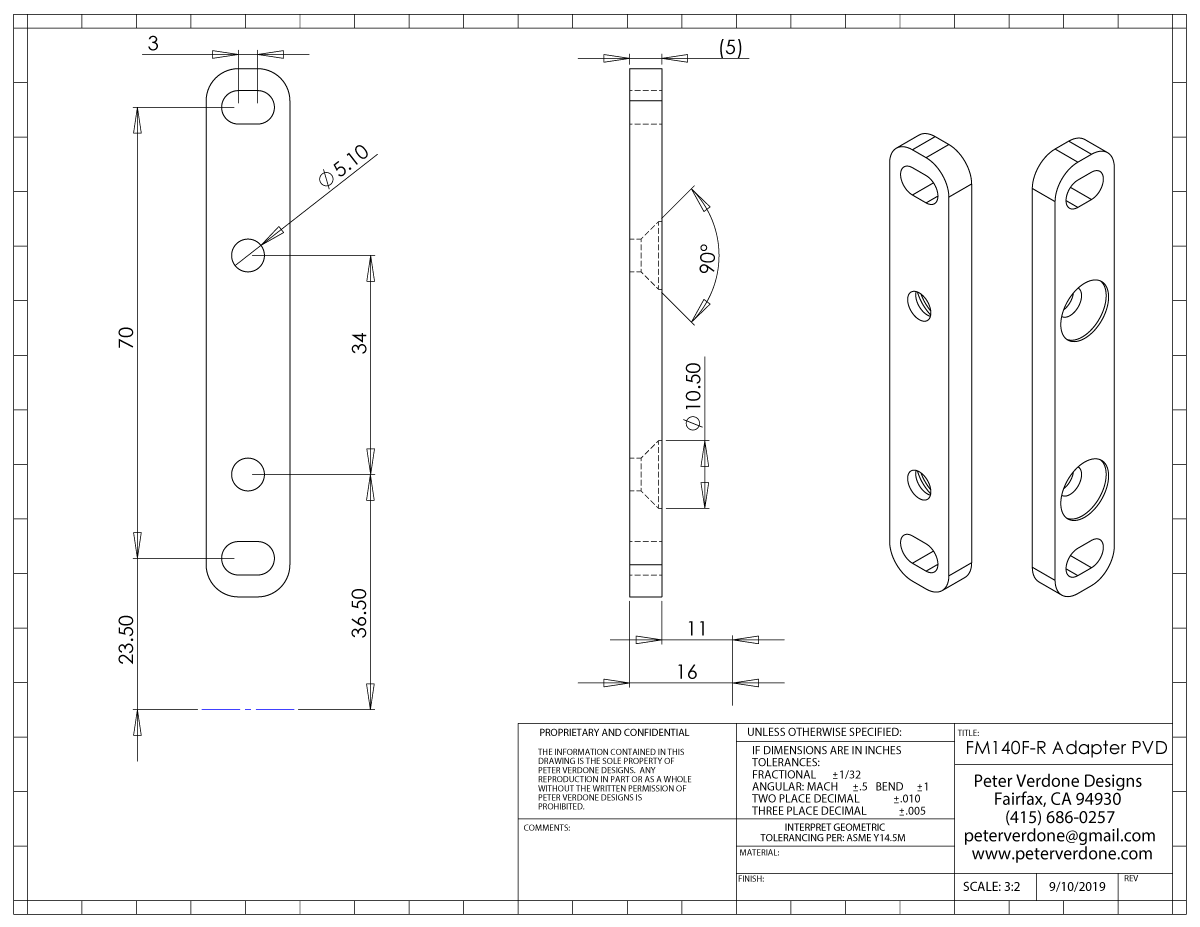

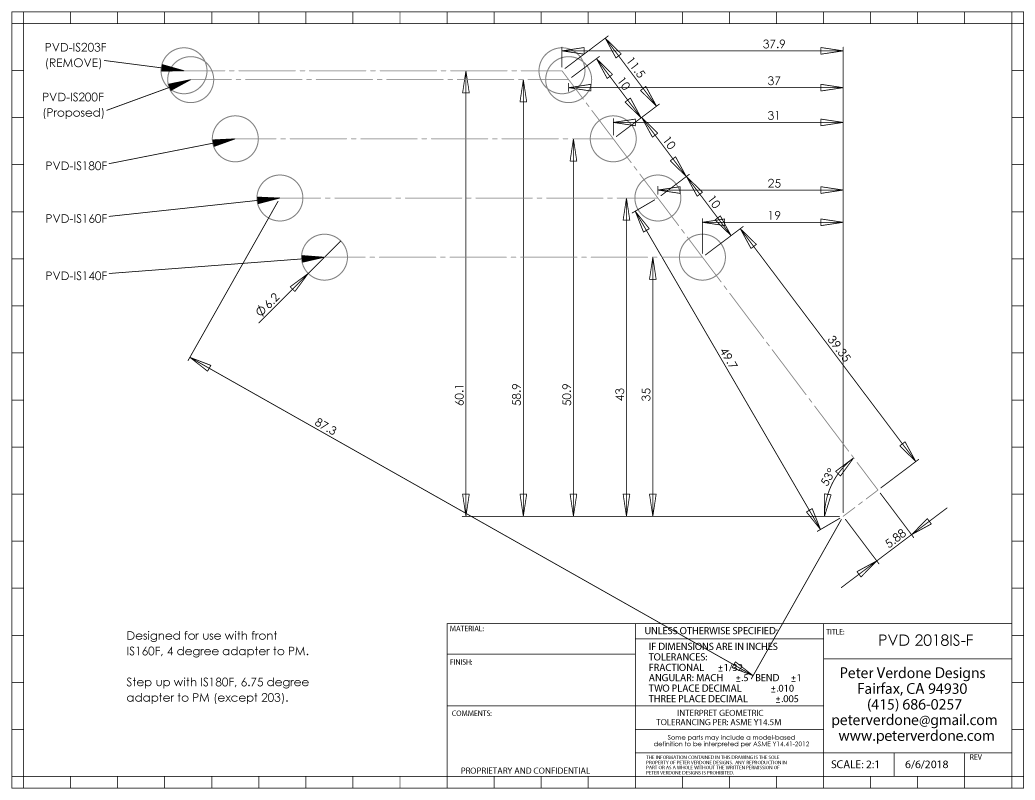

For front Flat Mount, things are a little less pretty. There is a bit of interference with bolt locations as things change with the adapters. In addition to that, the ascetics of the larger adapter solutions kinda suck. Thus, just one adapter will be preferred for crossover, the FM140F to PM140, 16 degree adapter. To step up, the FM140F to PM160, 2 degree adapter is used. This doesn’t look good though. Both Shimano and TRP follow these angles.

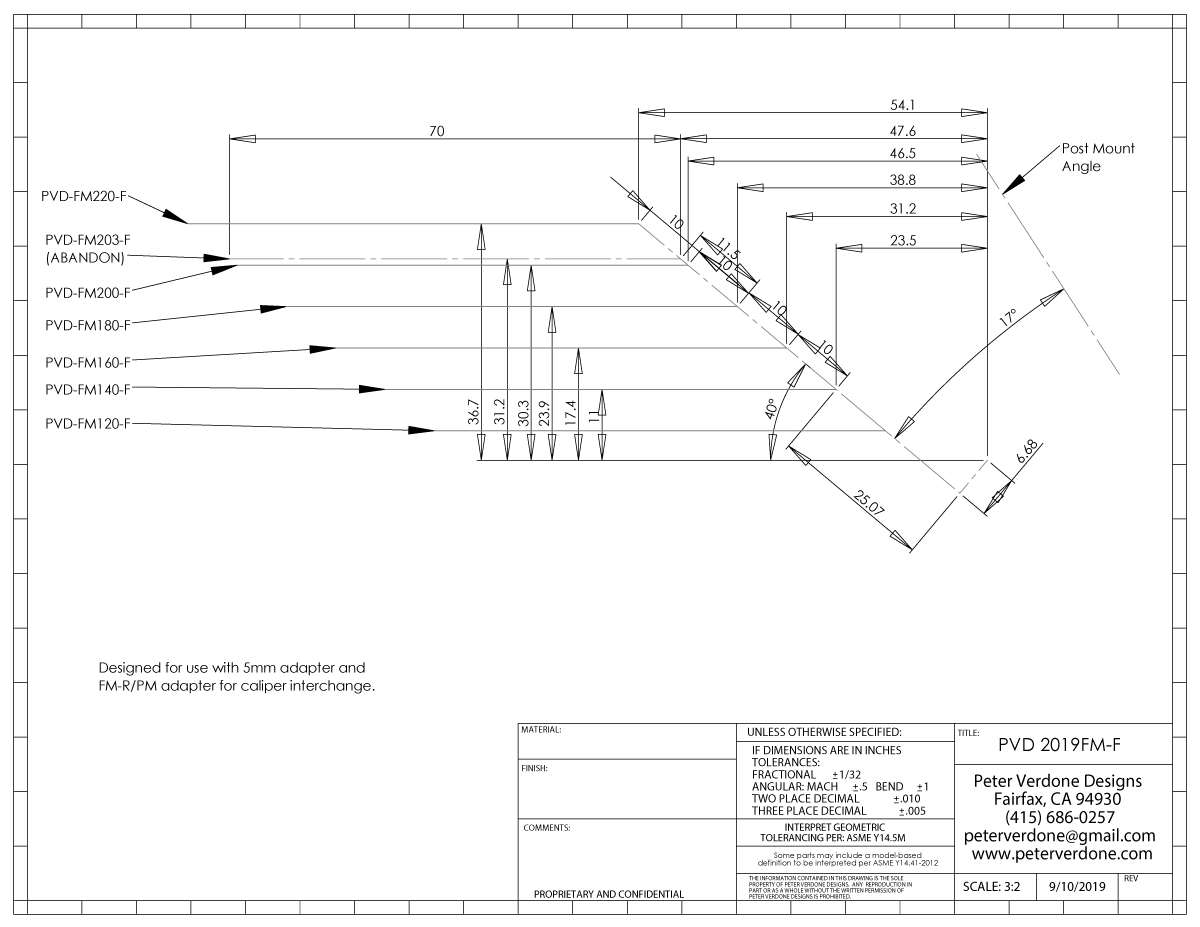

The solution, is a 5mm adapter from Flat Mount Front to Flat mount Rear. Then we just mount Rear adapters to that. This is the only current workable solution and it allows for simpler tooling and understanding of the system.

Flat mount front at 40 degrees with 17 degree translation from Post Mount:

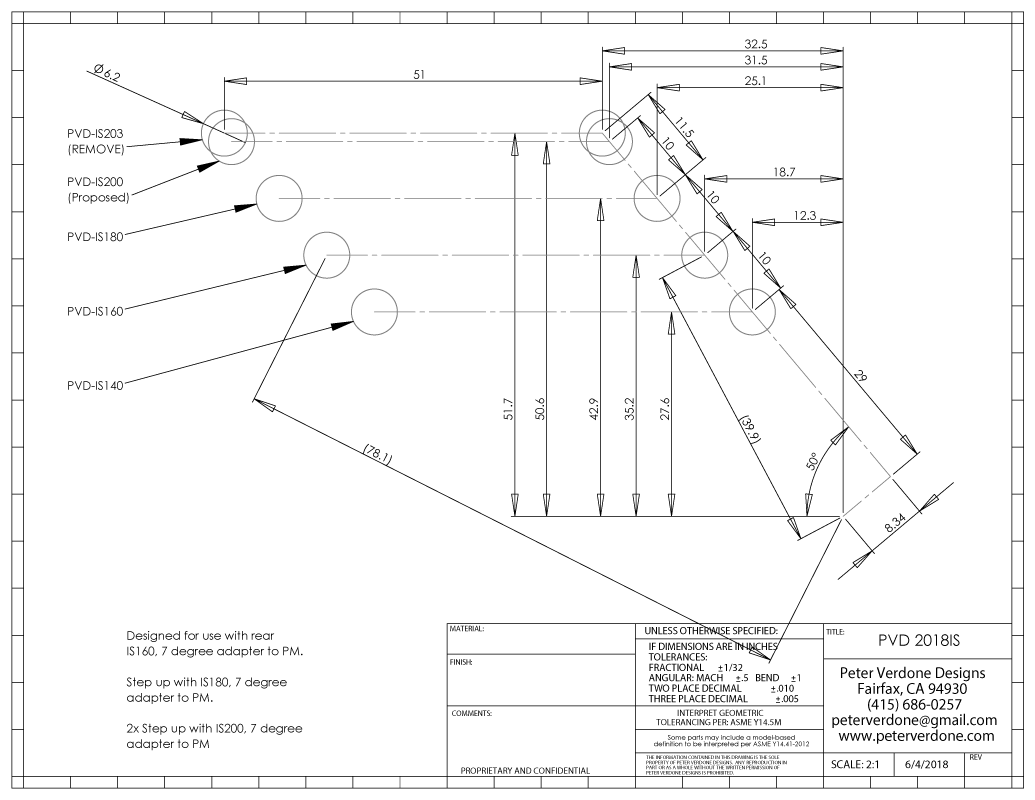

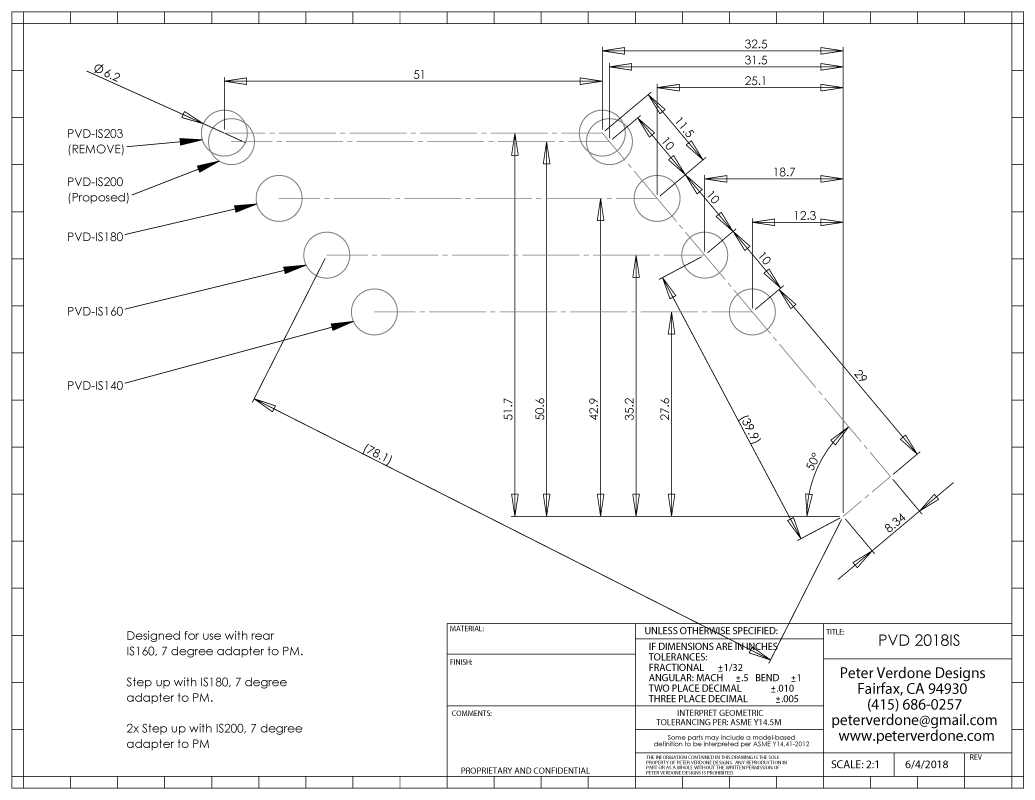

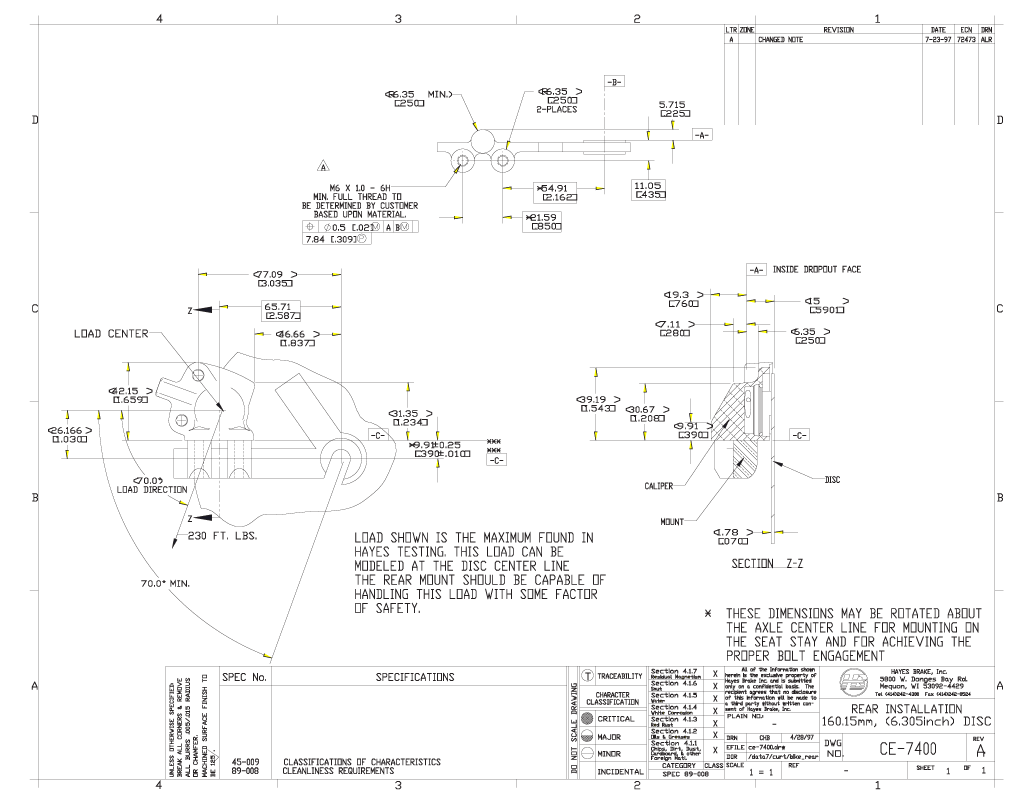

International Standard, IS2000:

With International Standard or IS2000, only IS160 is specified but a sensible construction can be made to allow use of the IS160R/PM160R adapter in any rotor configuration. The placement will match the positioning that the originally defined PM160 caliper takes, rather than that in my refined system. Further, stepping up or down with other adapters will cause some shift, the problem with the PM160 placement. In a perfect world, new adapters would be made to the new streamlined spec.

Still, the IS160 adapters will be slightly off and should be updated. IS really has the most problems but other than special cases it’s use is gone. They are still usable. This refinement effects very little of the current performance market.

Shimano Adapters use a 7 degree translation for rear and a 4 degree translation for the front. Tektro uses a 7.3 and 4.5 degree translation. We’ll base this on Shimano numbers.

Note: I do use IS160R/PM180 adapters with a 160mm rotor for the rear of my custom hardtails. PVD StepDown , that my be gettin updated. It’s pretty slick. Looks great, works great, lightweight. We still have uses for all of these parts. It’s about choices!

International Standard rear connects to the Post Mount system by a 7 degree translation

IS front via 4 degrees.

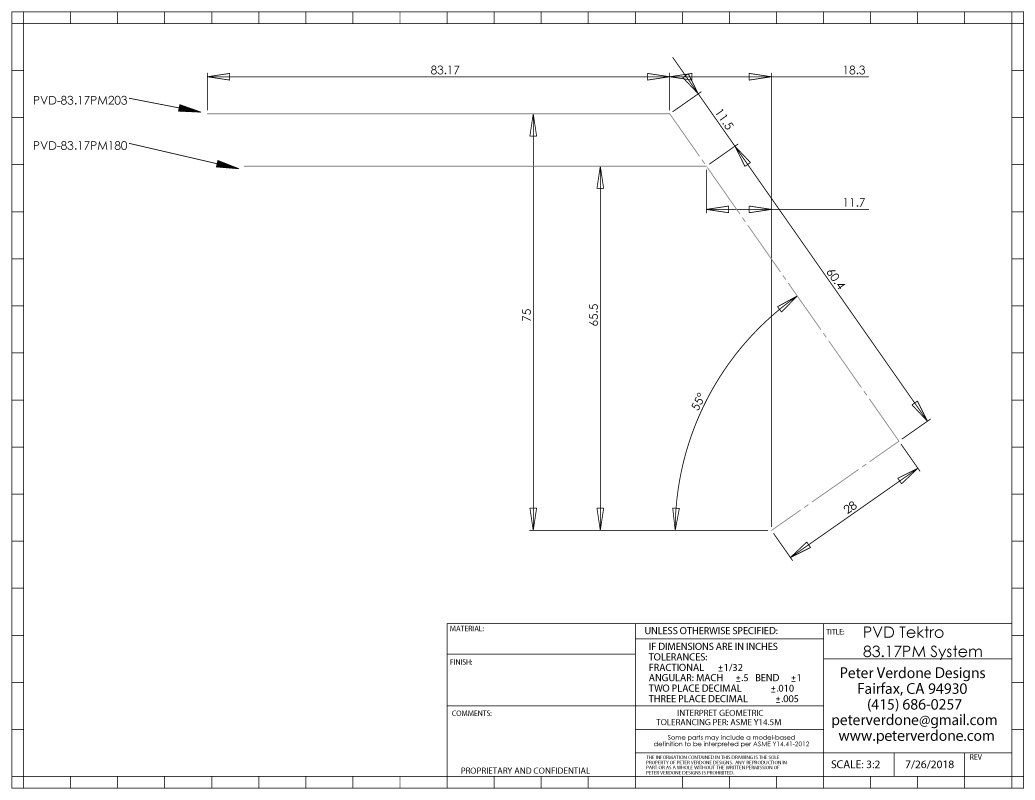

83.17mm Post Mount:

A new system coming into the ecosystem because of the needs of heavy and powerful mopeds (ebikes) with wheel sensor control systems. A post mount system with 83.17mm spacing. I’m seeing this on the Dorado, TEKTRO HD-E710 System. Not much is known at this point outside of the product page. Rated for 45 km/hr (28 mph). The rotors are 2.3mm thick compared to most pedal bikes at 1.8mm.

I’m working on getting more info through their DO4.0 Series adapters. They connect to the frame via IS2000 and work for rotor diameters of 180mm and 203mm. An approximation of the locations is as below. Final numbers have not been released.

SRAM CPS Calipers:

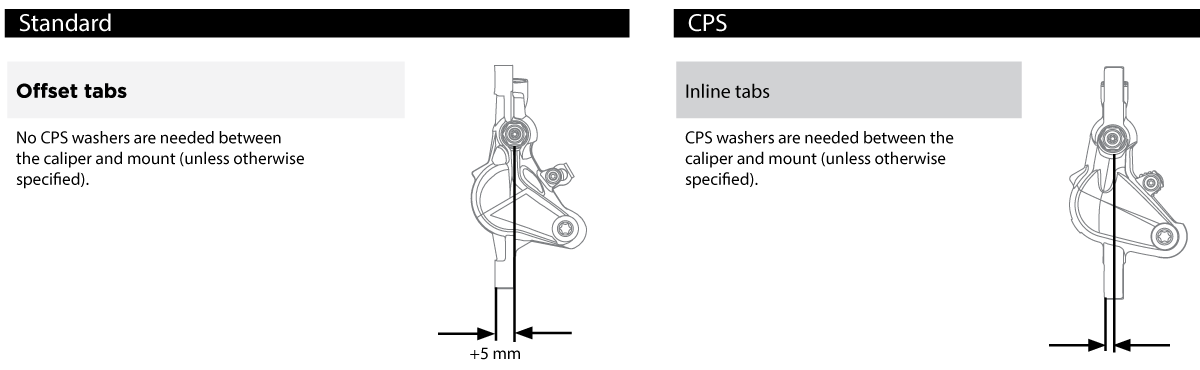

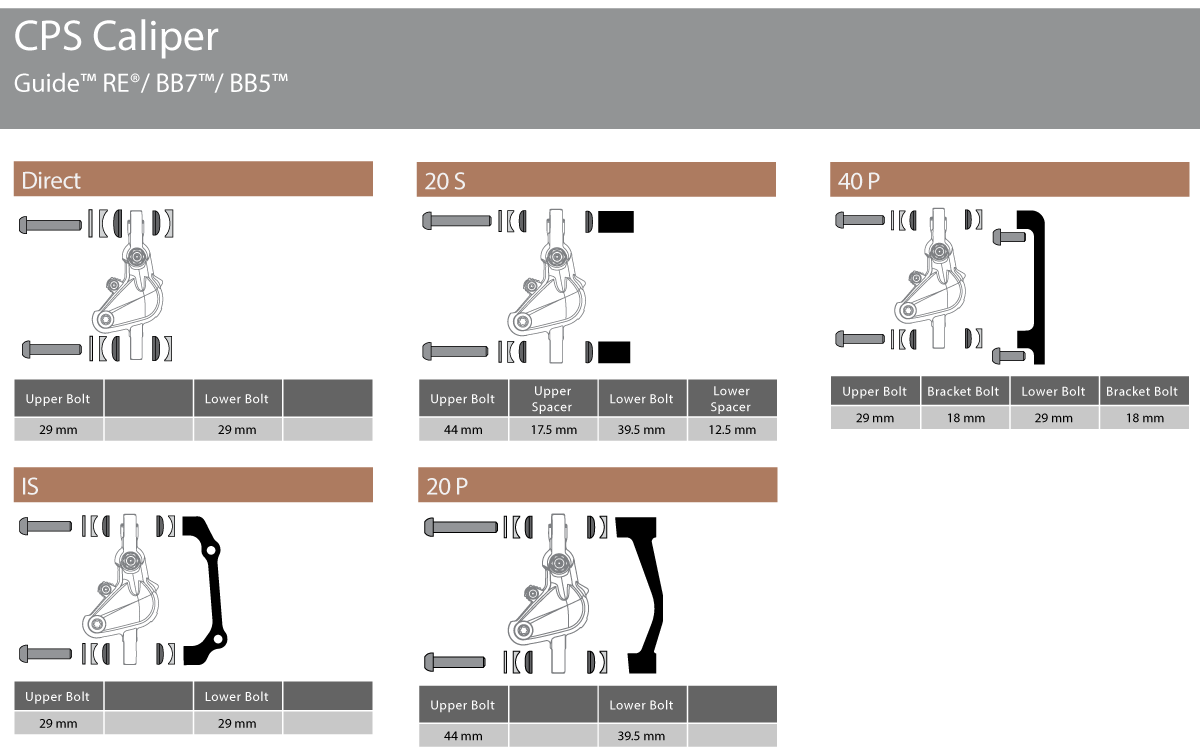

One part that shows up on many low end and OEM bikes with SRAM parts are Avid’s Tri-Align™ Caliper Positioning System™. These calipers are intended to be mounted with cup washers beneath them, thus, having a different deck height than other calipers that they look similar to. These have caught many experienced technician off guard over the years.

- 2019 Shimano Disc Brake Standards

- 2018 SRAM Brake Mounting Standards

- 2012 Avid Post Mount Standard

- 2012 Magura Post Mount Standard

- 2018 Tektro Caliper Adapters