In response to whether he should give up a project, Thomas Edison once said, “I have not failed 10,000 times—I’ve successfully found 10,000 ways that will not work.”

I’ve been welding my own bike frames, forks, and handlebars together since 2006. That’s about 16 years. Before that, I had a good amount of experience preparing and finishing parts for weld. Granted, I don’t weld a lot of product in a given year but 2-4 bikes a year over that amount of time is significant.

In all that time, I haven’t had a single welding failure. None. That isn’t to say that I haven’t had any failures. I’ve had lots and lots, just not in the actual weld.

The closest that I got was on the PVD Supermarine Spitfire (2020). The top tube failed, this attributed to lack of wall thickness in a design that pushed a geometry that completely overwhelmed the thin tube. That was corrected with new tubes that I’ve used since without issue.

I was out riding, just phoning in a quick Tamo loop. Something to say that I rode today as I had a bit of work to do on my computer and was distracted. I was pedaling along, chilling out to the beats. I drop into Wagon Wheel. A nice easy flow but nothing amazing or super fast. I had just cleared the first rock garden on the trail when ‘CRACK’ and the ground was coming up to me fast.

The handlebar had broken clean off and I understood most of the failure before I hit the ground.

The crazy part of all of this is that I had fully brought these bars to the limits just a couple of weeks ago. On October 2, we closed out Northstar and I rode this bike. The riding done there is so much more extreme than anything done at Tamarancho. I lost count of how many times I landed with all my weight on the bars. There was no sign of trouble. Granted, I can’t remember checking the handlebar welds after that trip. Still, this is analogous to going on a few tours of duty in a war only to come home and get killed slipping in the shower.

Strangely, I’ve gotten used to the sight of the ground coming up to meet my face like this. My third handlebar failure in less than 3 years. That sounds pretty bad…and it is. Still, it’s part of the game. ‘Move fast and break things’ means something important. I know a lot of people that might end up doing something some day. ‘Might’. That’s IF they get done checking, double checking, making sure, asking permission, and being utterly terrified of making any kind of mistake. At the end of all that, they’ll still get taken down to earth by a mistake. They’ll screw something up, something they didn’t figure on. They could have moved forward years earlier without imagining that they could sort the problem without being IN the problem. I’m not making an argument against doing the work. I certainly argue to do the work. Just move forward. Keep the momentum.

My first bar failure was in January 2020 when the Spitfire bars and wheel exploded on a drop off the Nike site in China Camp. I got to get some nice titanium bling in my collarbone from that. Whatever caused that crash, the filament wound carbon fiber failed in the bars. That was corrected with a new layup tube. Then, in February 2022, another handlebar failure while bombing down Hobo. That was a failure in 3D print wall thickness and engineering. In the most recent case, a fabricated handlebar, the weld failed on an extremely highly stressed joint. So, three handlebar failures but each for a different reason than the last.

I’ve been claiming for years to be a terrible welder. You can find evidence of me saying this throughout my work. I’ve finally proven it without a doubt. Like many bad welders, I have a joyful process of welding, grinding, rinsing, and repeating. It’s gross. I am ashamed but it’s better to be ashamed and do something than proud for doing nothing. That is the game many have to play, make the world bend to our will despite our short comings.

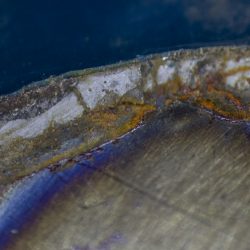

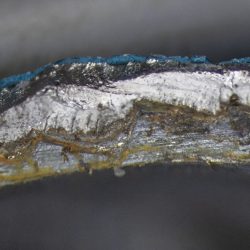

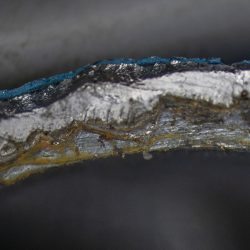

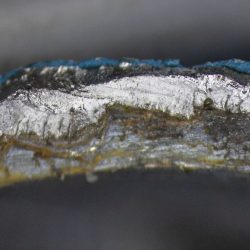

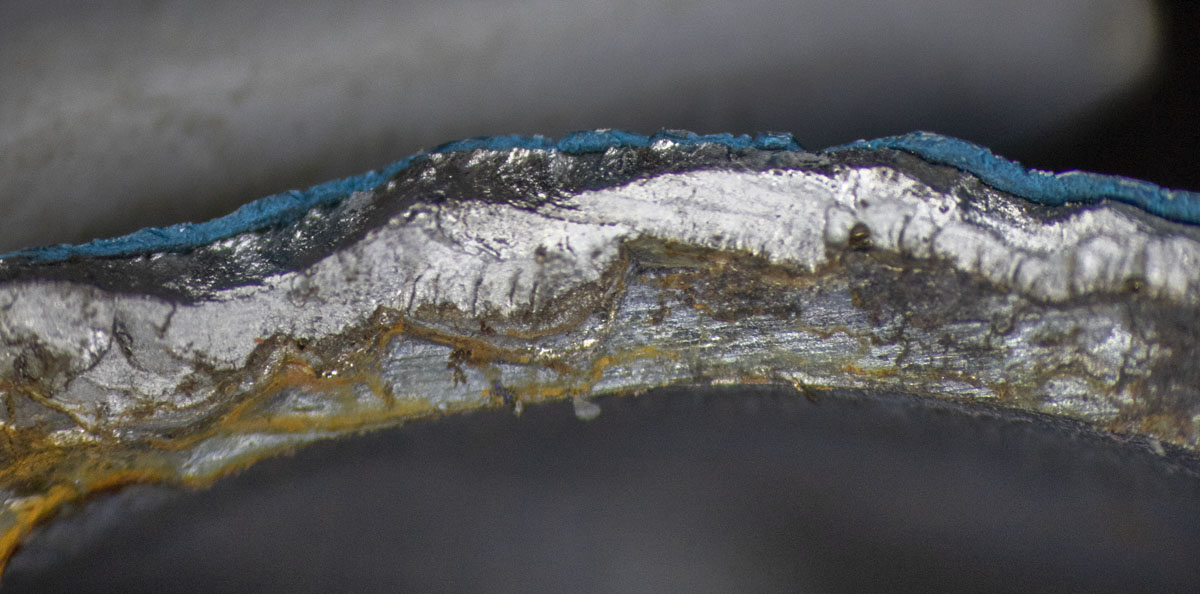

I got to the new microscope and imaged some of the area of the break. It’s really nice to so easily get high quality images of such hard to hold pieces.

Clearly, we are seeing a lack of penetration and a lack of weld material. With so little holding this joint together, it’s obvious that the failure was welding. Overzealous grinding and not enough heat in the initial pass.

Now, I need to take a good hard look at my welding and find a way to get more material into the joints, with full penetration, with it looking good. Ugh. I hate making bikes. I like designing and riding them. Hate making them.