Gambling is an art with a vicious side to it. We bet on black and by magic, we get black…over and over. We get cocky. We think we know what we are doing. Then, up comes red and we are busted again. The gambler always loses.

The first ride on the PVD Supermarine Spitfire went great. Everything that I had been shooting for had been realized. Improved handling with less wheel flop. A softer front end and the new brake standards in place. A completely unrestricted and aggressive geometry. On that first ride, we rode a good variety of trail. I rode down Elevators 4 and 5 at San Pedro Mountain Nike Site several times. Down Hitler and Back Ranch Fire Trail. Some stuff that was rough on the front end. Everything seemed to be fine.

Through all of this, my concern was the prototype fork. The wheel had been used for a few years and was in fine shape. The design of the handlebars had been thoroughly vetted on several previous bikes and put through their paces with success. I was worried about the fork snapping. Either the carbon spar or the unicrown bent lug holding them in place. I was very worried. I wanted it to work but I had zero experience with this sort of fork.

So, we start out on ride #2. I had originally intended to be riding some of the harder trails on Tam with the bike but I was convinced to head back to China Camp again for a Knight Drive start. Ronen, Aaron, Phillip, Brian, and a couple other bros. All young and strong. Me, all old and weak.

We start up the hill. A faster pace than I would have liked but I try to keep it stepped up. We circle around Bayview and get to Back Ranch Fire Trail. Of course, Ronen wants to go up it. Hell. Fine, but I just push up. Screw that pain. Klunkers are all about being able to get off and walk when sensible. Of course, Ronen then wants to ride up Maytag. Ugh. No. Pushing up again. Then he wants to ride up Q4. Do whatever, we’ll see you at the Nike Site.

Everybody shows up to the site but Ronen, Phil, and one of the bros. We fuck around for a while. Lots of drops down E4 and E5. It’s a busy day and there are several crews showing up and leaving at the top. Almost nobody is riding the elevators but me. Ronen and the others finally show up. It had been a while. Around the same time, a spunky 12 year old shows up, eager to get on it. It’s very rare to have anyone around that’s on the stoke and even more rare when it’s a little kid. Ronen and I are pumped. Ronen shows off his leap of faith onto the Nike slap. This blows the kids mind. I’m heckling hard and dropping into E4 and E5, egging the kid on. Things are good.

So this is the money shot; I’m dropping into E4, the roll in with the swoop drop. It’s pretty fun and few folks attempt it due to the forced drop in the roll in. I’m going in at a slower speed as I’m still being cautious about the fork and only trying to build on what had been proven. I decide to pull up a little harder on the bars to get a little more hit on the front end. Nothing crazy. I had been keeping things low on this but I wanted to get to something more presentable.

….I can’t remember the moment of the crash yet…..

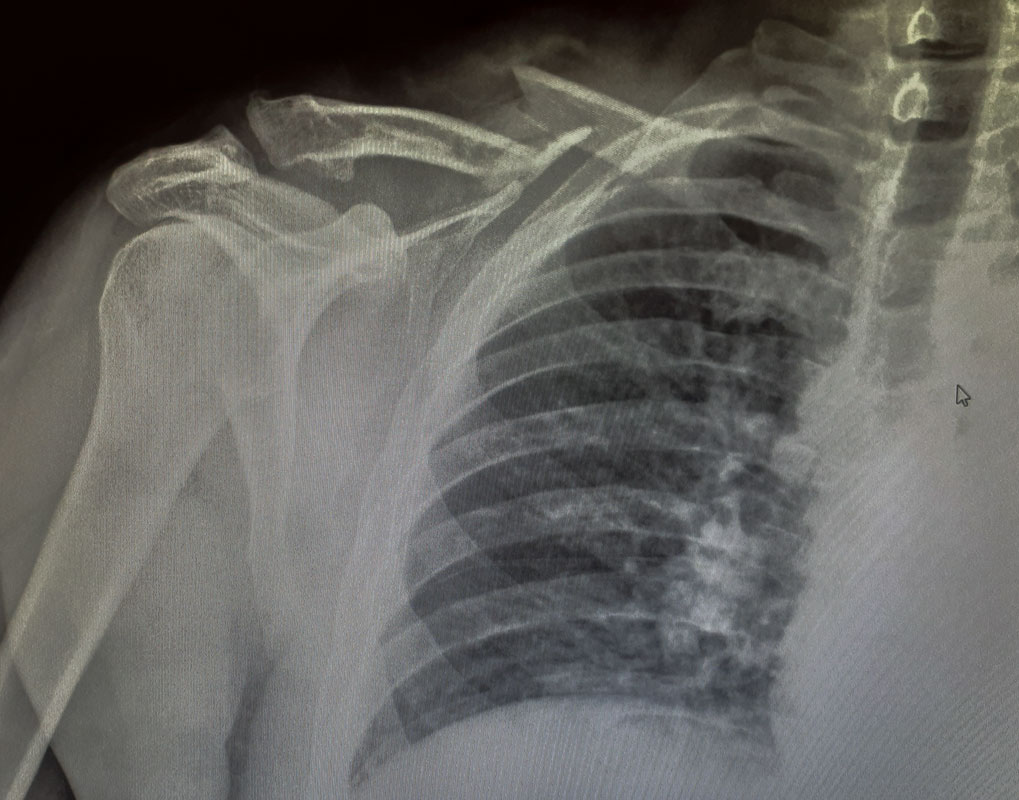

I’m on the ground. The wind knocked out of me hard. I was babbling. I guess people were talking to me and there were a few conversations that I also can’t remember. I had a pretty bad concussion and I was in full loop. My shoulder was crunching and I hurt bad in the ribs. I was pretty well pasted.

The guys start figuring out what to do with me. About 20 minutes after the crash I start coming out of the fog and get a bit more coherent. Brian was driving the truck up the road to get me and bring me to the hospital. My wife was on the way to meet us there. I was fucked up….and my bike was in worse shape.

We still haven’t sorted it out. Nobody saw the crash and there was no footage. Everyone says they heard this loud CRACK! sound and that of my body slamming into earth and then me gasping for air. It must have been fucking brutal. It certainly wasn’t a crash because riding as this was a very simple hit that I was doing at 1/2 speed and that I’ve done about one hundred times. Something on the bike broke and sent me into the ground.

My current speculation is that the right bar snapped when I hit the G out and the front wheel hit the ground. This may have jackknifed the front end to fail the wheel. My body then hit the broken bar and bruised my rib. Then, my head and shoulders hit the ground hard, breaking my clavicle and bruising my skull and concussing me hard.

The problem here is that the bars are a proven design. The wheel is a proven wheel. Unless it was the new tire blowing off the bead at impact, it’s really had to explain. Another concept is that there was an issue with the carbon tube that I got from my supplier. I’m still looking into this. It would be nice to have some non-destructive testing that I could use to look at my stock. This would be useful around carbon bikes in general. I’m looking into some tools for ultrasonic and thermographic imaging now. I really can’t afford a $25k FLIR A655sc. Gotta find out more. Maybe an Olympus Epoch Ultrasonic flaw detector for $3k (used)

What this means is that I’m going to have to make a real test fixture and go through a proper test protocol on the handlebar design. I have a copy of the protocols of: DIN Plus, Taiwan Bicycle Industry Standard (TBIS), Asia-Pacific Congress on Sports Technology (APCST), National Standards Authority of Ireland (NSAI).

The way the wheel broke is very odd. I’ve never seen anything like it before but then again, this is the widest rim I’ve ever had, i40mm. There was a Cushcore Plus in the wheel which adds more questions. Even with a cushcore the rim failed like this? It should have been impervious. I’m going to replace it with an i45 rim that’s a little tougher and has more stance.

There is good news in all this…the fork didn’t break.

I’ve become known as someone that pushes the limits of bike design. Out at the bleeding edge of what we think we can get away with. I’m good, or at least I think I am, because of how much I’ve been able to move the bar while far away from what everyone else is doing. This comes at a real cost, both in money and flesh. I build things that don’t work. I crash hard testing ideas. It is not safe to do what I do. Certainly not at the scale I’m forced to work at. Risk and reward are the world of the gambler. This day, I lost my bet.

UPDATE 2020-01-29

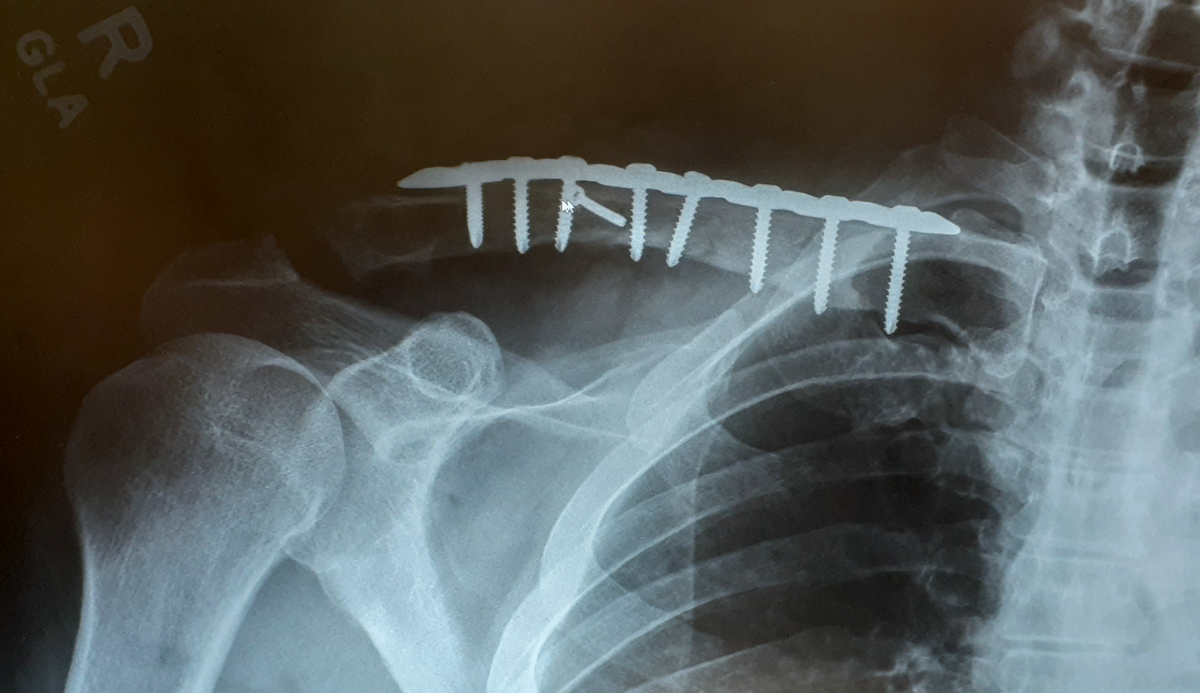

Surgery is done. It took over a week to get it but now I’m healing and will be making some tools a bit before being able to ride again.

I’ve had several discussions with composites experts both inside and outside of the bicycle industry about what may have gone wrong. A very fancy PhD in composites engineering and testing said basically, “Your engineering is fine. You just got unlucky” We discussed materials testing so I can validate what comes in from my suppliers.

I put off talking with my supplier about the issue until I really knew what I was talking about and what it could have been. After a week and a half, I sent them an email. I was really stoked that when I did reach out to them in the email, their engineers got back to me within the hour and have done a lot to help me sort out solutions. No CYA bull$hit. Per our lengthy conversation, I’m going to move to similarly dimensioned tube but with a different layup schedule and pre-preg rather than filament wound. This should add a lot more strength with just a little more stiffness and more consistency in the composition. Hopefully this all works out and in in time, move to a custom layup that has the flex I want with the strength I need.

I may still be acquiring an ultrasonic flaw detector/thickness gauge. It’s an expensive tool and may not really work as well as needed in this particular application. The physical test seems superior here. It would still be a nice tool to have around as I would be able to examine other carbon and metal bikes for the changing wall thicknesses in their structures.

I’ve produced and used 5 handlebar sets using this composite design. All have been ridden very hard and have shown no sign of issue other than this one. This one arm failed on it’s second use so the material is the issue being looked at. That’s 1 out of 10 bar stanchions doing this. Not something I’m looking for but not as bad as some folks make it up to be.

WTB has taken care of me with the wheel. They’re local so they came by my house and we discussed the failures and the wheel. They replaced the spokes and rim with a KOM Tough 622-45 which should be much stronger than the old Scraper 622-40. The addition of supporting ribs in the rim should really help prevent any possibility of collapse in the future. We discussed the issues pertaining to this failure at length. One problem is that I’m using these rims in a much harder manner than most of the plus tire crowd. I may be pushing the wheels a little harder than most of the plus crowd does with enduro style riding and a rigid fork.

A plate and nine screws holding 4 pieces of clavicle together.