It was time to take another look at a ‘problem’ long in the making. Holding crap to a bicycle frame.

In the bicycle world, we’ve been using a system to hold water bottles to a bicycle developed sometime in the 1930’s(?). Little has been done since. A hole is drilled in the tube and threaded cage bosses are brazed in place. I’ve never been a fan of relying on traditional water bottle cage bosses for mounting anything more than a water bottle. It seems too flimsy. It’s simply not a reasonable solution. It’s not….good.

We’re going to have to back up a little bit to frame this. What are we doing in this part of the bike?…

I first started adding bag straps to my bikes starting with the 2020 PVD Supermarine Spitfire klunker. Then, they were constructed from a simple sheet metal part with some slight detail cut into them. These developed and improved on each bike. The goad was simple, a good way to carry crap on a bike. A simple strap loop. There were bad options and terrible options. This seemed a lot better, and it was.

In later bikes, these were 3d printed and took on a different shape and level of refinement. They got wider and far more secure. Here on the 2023 PVD Millennium Falcon.

Another thing about the bottle mounting that surround this problem is that on the seat tube, a separate type of system was being used. This to keep the inside of the tube clear for dropper post insertion. Essentially, this is a threaded post projecting from the tube. A nut is used rather than a screw. This, on the 2018 PVD Bird of Prey, is about as clean as that can be done.

More, long bikes and modern riding put a huge amount of force into the down tube. To help protect the down tube from failures that come from holes drilled for water bottle bosses, I’d begun supporting the area with additional surface area. Again, shown on the 2023 PVD Millennium Falcon.

This is a photo of the type of failure that I’m talking about. This was a photo found on the internet and is not of my work. Even with the terrible craftsmanship and a host of problems, it shows the kind of crack propagation that I’m discussing. I worry about stuff like this. It wakes me from my sleep.

Over time, using the strap system and doing most of my riding post COVID without a backpack, I started needing more. More water, more tooling, more carrying capacity, especially for a pump. This starts turning into a mess.

There had to be a better way. How about taking all these problems and solve them in one go?

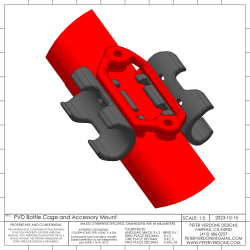

The details designed into the new system:

- No holes are drilled in the down tube or seat tube, keeping them strong

- Significantly improved connection to the tube makes bearing heavy loads with vibration and accelerations sensible

- The bottle cage has a broad flat interface to help support it when connected, keeping it solid

- A single mount with a host of options makes for a dense package on the bike

- A 40mm bag strap guide keeps things in place

- Bag rails are widely spaced but within the tube to keep cleaner looks

- Easily printed PLA accessory holders are very securely fastened with cable ties and the tube for support

- Accessory binders can be produced for almost any shaped luggage

- Similar system used on seat tubes, down tubes, forks, handlebars, or anywhere on the bike

- Since no holes are drilled, the mount can be moved in between paint jobs. This is very cool.

Shown below with a bottle, pump mount, and a watertight storage tube. More work will show up in this area in the next few months as I figure out the right path to take.

The new bottle cage/strap/aux mounts are pretty cool. Notice that no holes were needed to be cut in the down tube, keeping it very strong. I was worried that they would look like clutter on the frame but once everything is strapped in place, it look like normal…just with more options. The pump is super solid even without a security tie. The large waterproof cylinder is a test of another concept for tool stash.

It looks pretty cool just bare on the frame, once you get past the unfamiliar looks.

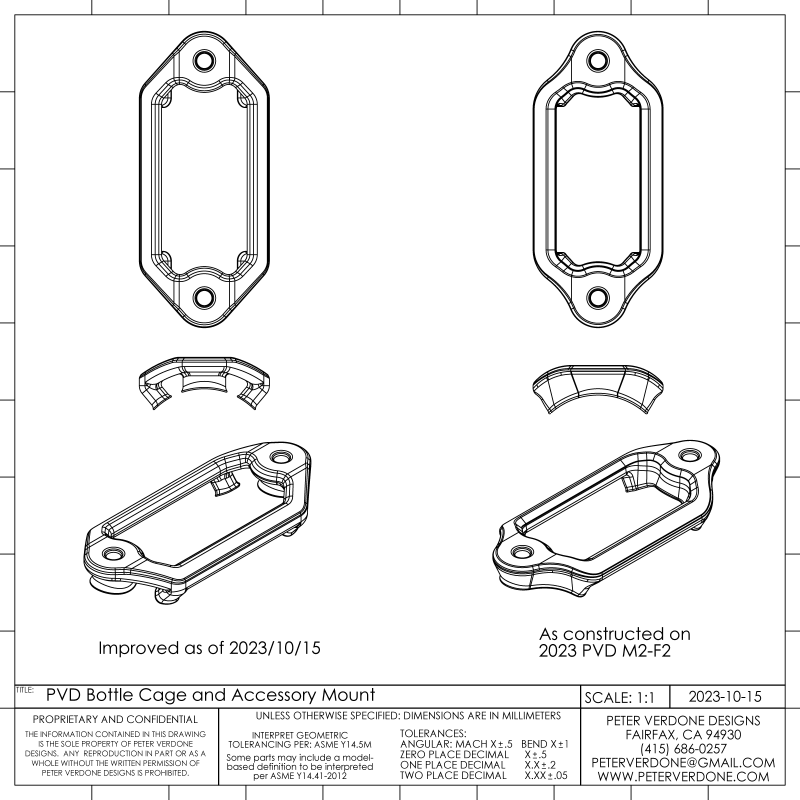

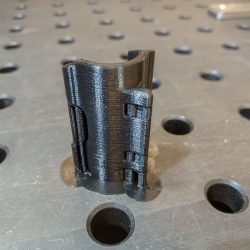

Since producing that first prototype and preparing for this post, I’ve done some work on the shape of the part. I’ve improved it a bit from a cosmetic and engineering sense. It looks lighter and is. It’s got better detailing on the insides keeping it as strong. It’s also slightly more tucked into the frame.

Even more important, a pair of tie down locations separate from the strap guide have been produced in the mount. Yet another detail level that will produce further invention. This is the development game.

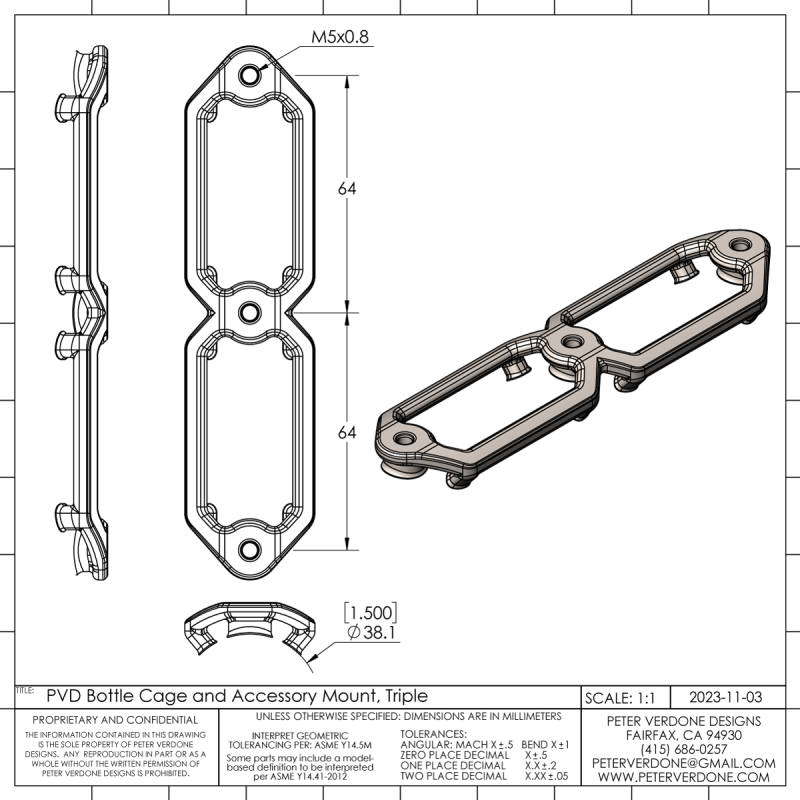

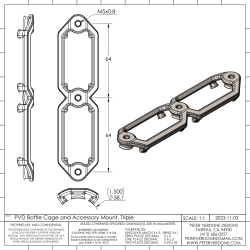

One detail that has been dropped from my bicycle work is the triple bolt design. It makes a lot of sense to do this as optional locating of the bottle and stuff are made. I’ve done it for many years and took advantage of it so infrequently that it seemed time to give it up. Makes sense, not a thing. For those that do need this feature, a special mount design could be made with 3 threaded locations, or two units could be placed in series for some serious carrying ability.

Since I have some reworks planned for some older bikes that have triple drilling on the down tubes, I did a quick triple version of the mount so that a full modernization could take place. this has issues but it didn’t take much of my time.

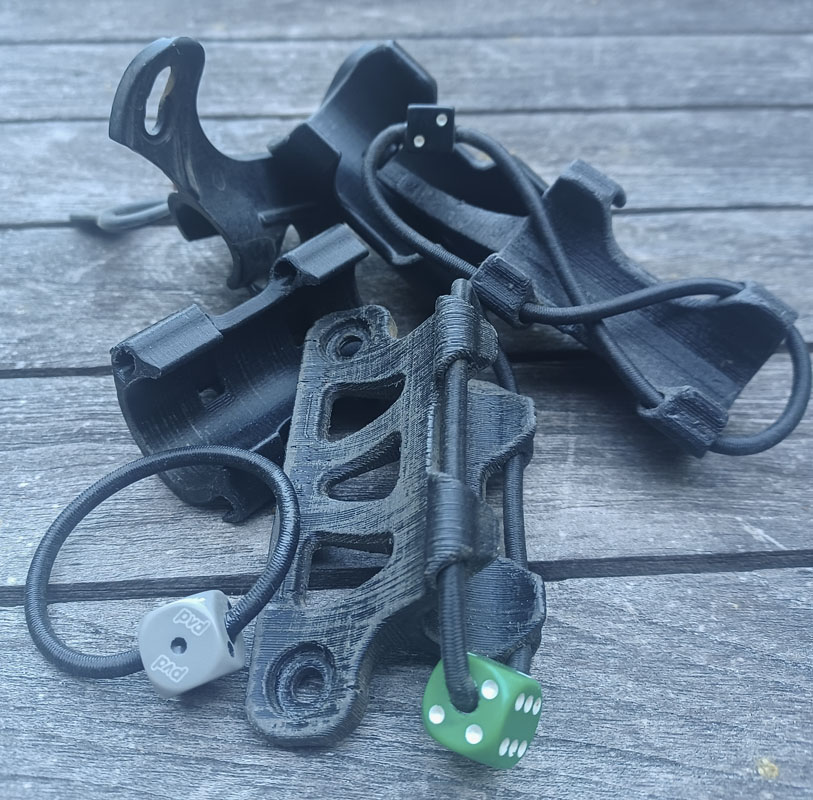

Developing the auxiliary holders has been going on for a while. I have a bit of carnage behind me there. A few years ago I was working to get the pump connected to the frame securely in a way the the commercially available product didn’t. I had a few rounds of work into that and tabled it until now.

I had been developing it with a bungee tie for security. In the recent modeling, I put more effort into the geometry of the grip and it’s now so secure that I dropped the tie entirely. That cleaned up the look a lot.