It’s finally time for a new Millennium Falcon. I’ve been waiting to do this for when I got to an important phase in my development. ‘Millennium Falcon’ is one of the special names in infamous spacecraft category. Few names command such respect and honor.

While the Falcon is remembered for it’s roll in helping a rebellion defeat an empire, it was at it’s heart a smugglers ship. Outlaw stuff. A bootlegger. I’m a trail poacher and this speaks to my heart. Flying behind enemy lines and pulling off another caper is the game we play. That makes the Falcon very special to me and riders like me.

This would be the second of my bikes with this name.

The Millennium Falcon. A Corellian YT-1300 Light Freighter, highly modified while owned by Lando Calrissian.

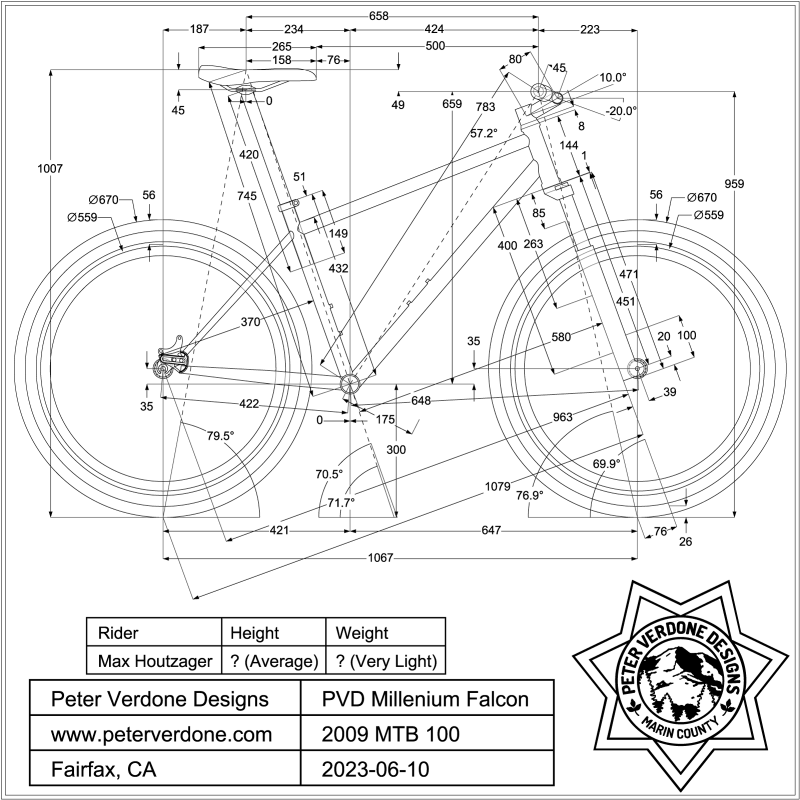

The 2009 singlespeed race bike that I produced for local rising star racer Max Houtzager also carried the Falcon name.Max, Will, and Kate were a crew and working their way to the World Cup. One of them made it and married the other.

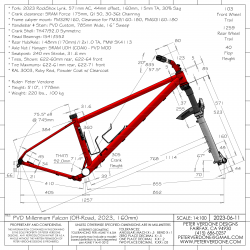

At the time, this bike was very cutting edge, as I like all of my builds to be. But this was before the modern era of bike design. Dropper posts were just starting to show up but were far from an everyday sight. I was still using very long carbon fiber seat posts to get flex under the saddle.

- 26″ Wheels

- Extremely short front end

- 100mm suspension

- No dropper

- Very slack seat angle

- Quick releases!

- Juicy brakes

None of that is what is really special or important about this bike. Few would know what made it such a moment in my journey. This bike was important.

Max was working with local trainer Dario Fredrick of Whole Athlete. Dario did (and does) a lot of fitting along with athlete consulting. I was just starting to figure out the basics of real bicycle design at the time. Max was a young racer and very connected to trends and what was going on in regional racing. He had expressed strong interest in using a 50mm stem on this bike.

Putting yourself back in 2009, this was a pretty wild request. What the hell was I supposed to do with that on a XC bike? How? Dario was pushing for a particular rider fit and I was trying to connect the dots to make the bike fast. I was struggling. I pushed back.

The reasons for the short stem were entirely fashion based and about a look. That made it hard to listen to. I pushed things around the way I understood designing the bike but it wasn’t coming together. I went with an 80mm stem instead. It was a compromised and questionable at best.

What was going on here is that the world was sending me a message. Design was changing. Super D bikes (later enduro bikes) were changing the shape of bikes and setup. Most of us were missing that. The pieces weren’t being explained by anyone and I wasn’t seeing it. Max pushing for a 50mm stem was a hint…and I didn’t take it.

I look back to this bike as an important moment in my journey. I didn’t see something when I should have. I needed to learn to listen. To look at things in different ways and from different directions to understand them. To be fair, nobody else was getting this either but I’m concerned with what I do and not others.

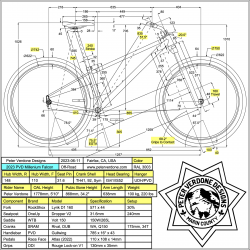

I updated the print for the 2009 bike to reflect modern sensibilities. We can see just how different this bike was from what is going on today…and this was a very progressive bike at the time.

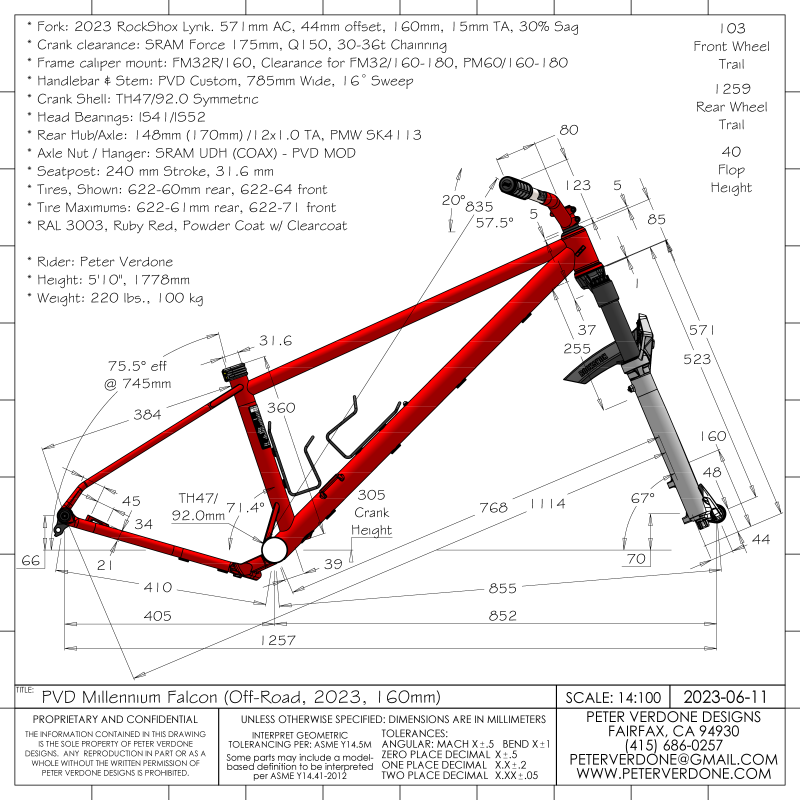

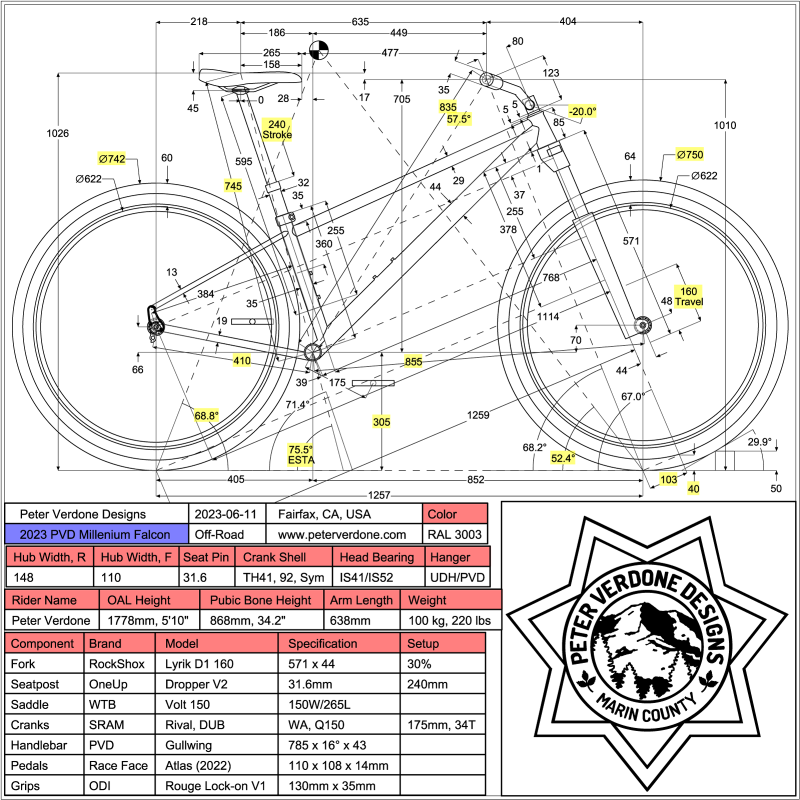

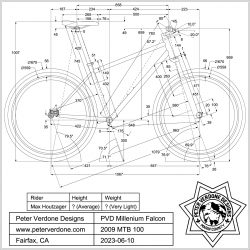

So we are moving up to 2023 and into a whole new era. Almost everything has changed in the last 14 years. Bikes are so much more capable, faster, heavier, and a lot more fun. More importantly, I’ve learned to listen to the world better and feed that into design.

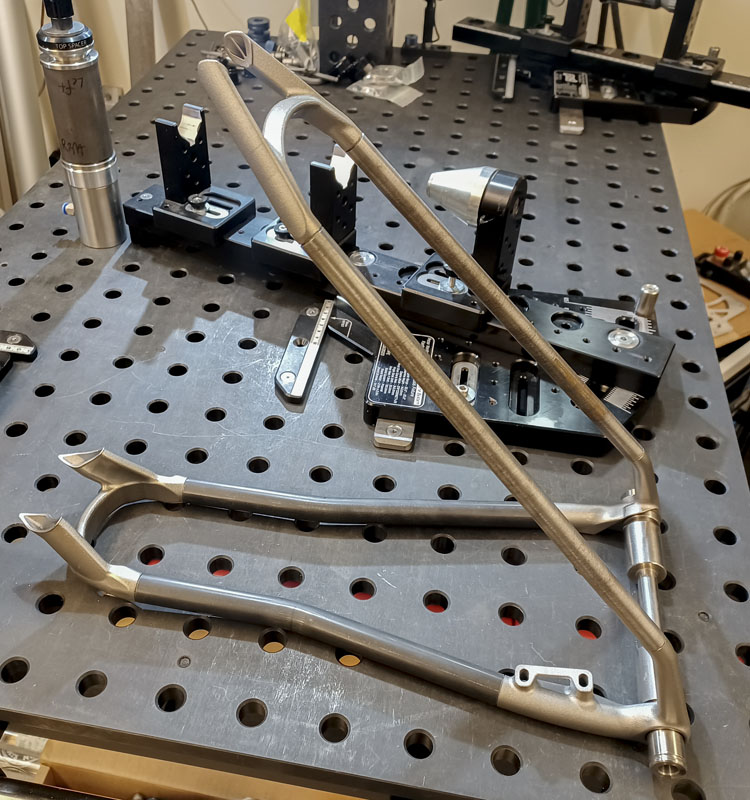

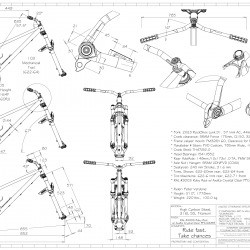

I (once again) reworked all the 3D print models. Developing the models has proven to take many iterations. The dropouts have gotten more elegant. The seatstay yoke is getting truly petite along with the seat tube supports. I want to improve the dropper route thing. I tried some new things with the cable braze-ons that haven’t worked and I need inspiration.

I’ve really moved the drop-chainstay yoke much further to something good. I’m not claiming that they are done but the directional shift is significant. The new shape is so much more compact, cleaner, and should be stronger and stiffer. It opens up more space for mud to clear. The look is just plain better.

I love that the rear end starts as a plug-n-play assembly. It’s a cool place to start the bike. It is a double edged sword as distortion in the prints can push the structure in the wrong directions. I’m working on a new tool that will help with that. Print distortion is becoming a big factor in what I’m doing.

While Windy received a SRAM UDH compatible dropout in her Vega frame, the Millennium Falcon is getting a proper SRAM T-Type dropout. There are different spatial and optimization requirements between the two that some are still unaware of. Thus, I’m calling this UDH/PVD-MOD. Among the differences is the lack of a guide fin on the derailleur. By cutting off the useless fin from the hanger, we can still use it, just without rearward rotation stop.

The headtube of the bike has been described in an earlier post. An improvement on the tube used on the 2023 PVD Lockheed 5B Vega. This is a fairly light, stout, and ultra short part. I’m loving these things.

I chose to start adding reinforcement washers under the water bottle braze-ons for this bike. I’ve been concerned that these holes in the tube could allow a crack to begin propagation as there is very little surface area under the braze-on to really support it. That hadn’t happened to me but I’ve always worried. I’ve also been concerned in how hard we are looking for these bosses to work in the modern scheme. These should be a nice insurance policy.

For the rear brake caliper, a SRAM(30.5°) FM160 mount is used with the intention that a FM140 to PM160 adapter will bring the caliper into position for a 180mm rotor. The SRAM FM specification may have gone unnoticed by many but it has been shown in their technical documents. They define a 30.5° translation in 9.865mm radial steps per 10mm of rotor radius. The math is shown on another post but is shown below.

- “SRAM Flat Mount R Top” = sin ( 30.5° ) * ( 39.57007816+ (( “Rotor Size” – 140 ) * 8.5/10/COS( 30.5° ) ) / 2 ) – cos ( 30.5 ) * 4.73908368

- “SRAM Flat Mount R Bolt #1” = cos ( 30.5° ) * ( 39.57007816 + (( “Rotor Size” – 140 ) * 8.5/10/COS( 30.5° ) ) / 2 ) + sin ( 30.5 ) * 4.73908368

- “SRAM Flat Mount R Bolt #2” = “SRAM Flat Mount R Bolt #1” + 34mm

The most shocking change that shows up on this bike is the appearance of the T47 crank shell interface. After about 14 years using PF41 I had to switch. It makes no good sense but the influencers have decided. I don’t like this as it’s stupid but forced by part and tool availability and support.

While a superior interface, PF41 has been nearly abandoned by the industry. The market needs to be sold stupid 30mm crank spindles and everybody is eating it up. They are better because 12 year olds are incredible engineers. The last straw was that the new SRAM t-type cranks and chainrings are clearly built on a 30mm format. If I want to play, I need to work with where things are going.

The problem then is what interface to choose for the 30mm spindles? The obvious choice is PF46…but the industry has nearly abandoned that or soon will. That leaves a threaded shell. It’s insulting to have to do this but their isn’t a better option. Few that take an engineering perspective on frame building believes in a threaded bearing interface. TH47. Dam.

So now I have a larger crank shell that limits geometry options. It’s got larger bearings so it’s a heavier system. The 30mm crank spindles are as stiff as needed, just like the 24mm spindles they replaced. On the plus side, more space has been taken up close to the crank reducing drivetrain options. I guess the more I lose the more I win, right?!

The setup for the bike is below. I’ve rotated the grips 1.5° higher about the crank shell from the 2022 PVD F-16 Fighting Falcon. From 835mm @ 56 degrees to 835mm @ 57.5 degrees. or 18mm rearward and 12mm higher. Same contact radius but a little more upright. I’ve been approximating something close to this and it’s been interesting. I also moved the saddle forward another 0.5°.

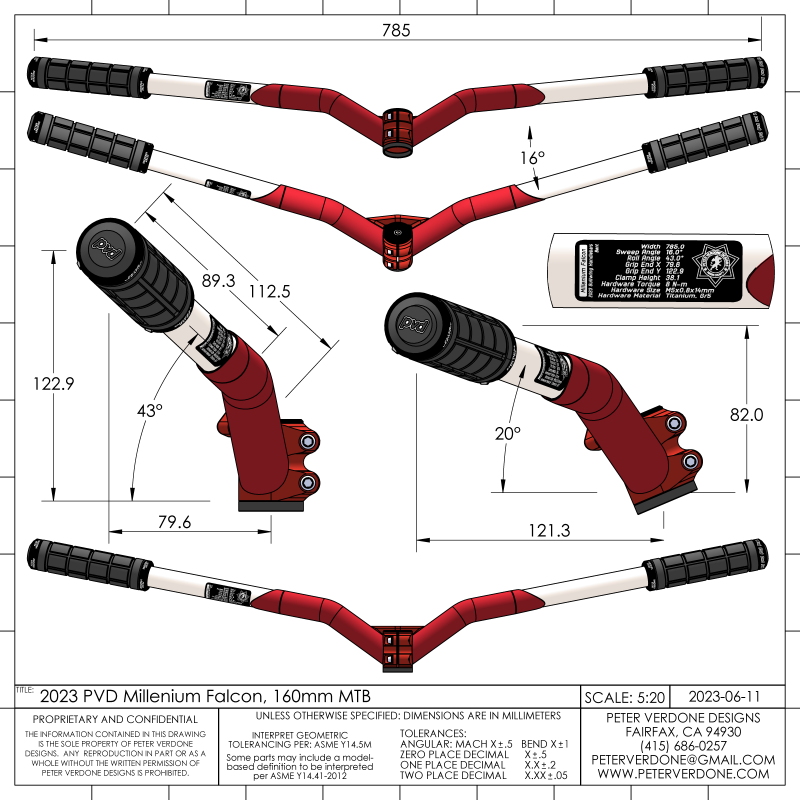

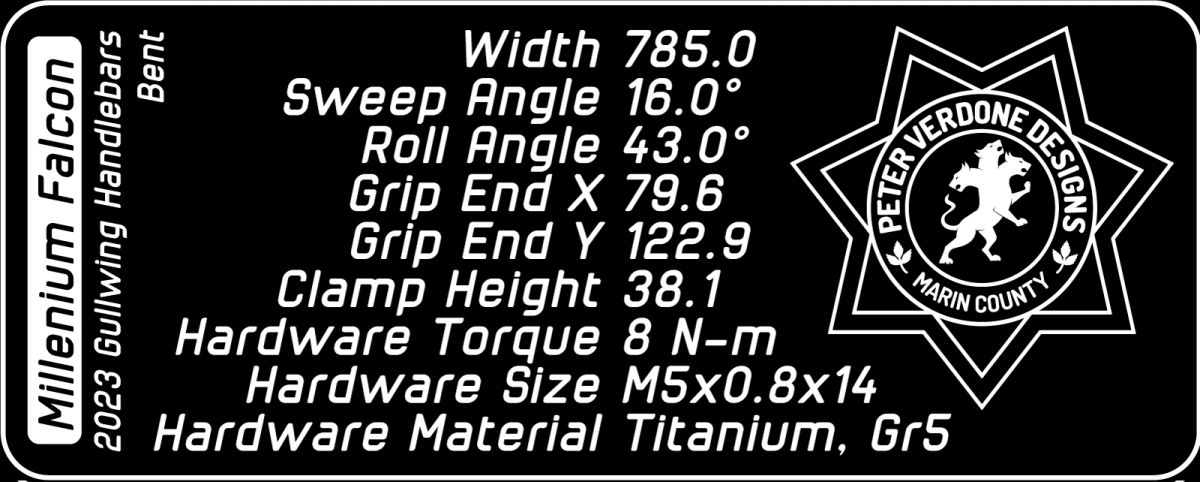

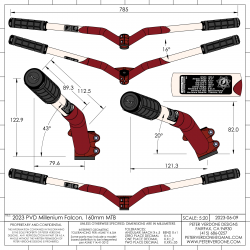

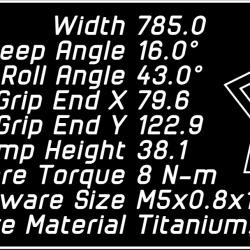

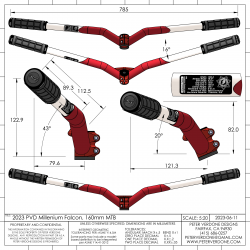

The handlebars are fun. The 16° back sweep is another move that his hopefully an improvement. I’ve been using 14 degree sweeps for a while on most of my current bikes other than the 2020 PVD Supermarine Spitfire which did have 16° 820mm bars. The Spitfire (Klunker) being a different type of bike.

My hope is that the 16 degree bars relax my wrist better than the 14° bars. It’s gotten so that if I get on a bike with just 9 degree sweep, which is very common on mountain bikes, I hurt and feel quite uncomfortable. 16° could be the key and testing will tell.

In designing the handlebars to work with the geometry of the frame and the grip location, I decided to reverse the binder and add a cross bar for the lugs. The binder reversal just makes things look a lot nicer in the profile.

The cross bar is a little insurance for more chairlift and extra hard hits. It’s also just another experiment in new concepts.

Of course, a bicycle is not just a frame and handlebars alone. This bike has been designed to specifically work with the new SRAM T-Type drivetrain. There are a few important factors that are being taken into account for this.

The dropout, as mentioned earlier, was shaped to optimize for the T-Type derailleur. I wanted as much of the thrust bearing in the mount to work against the dropout and for the shape to flow into the frame.

T-Type specifies a 55mm chainline compared to the typical 52mm chainline for a 148mm rear hub. They sell cranks that will work well for that…but I don’t want some janky Q174mm cranks on my bike. Q150mm cranks are what I’ve been liking. An inch wider is not acceptable. I needed to hack this a bit.

The T-Type chainrings are currently only available for SRAM 8-bolt fitment. That reduces the crank options that will work. Using the Rival crank and 3mm offset chainring, I can make a 52mm chainline (theoretically, 51mm actually). A 0mm chainring (11.6218.054.011 T-TYPE 34T, 0mm Offset, XXSL) would go out to 55mm but then the chain will be uncomfortably close to the crank arm and there is high likely of interaction. In the worst case, I will try this setup. It’s also a pricy option as those rings are about $110.

00.6118.612.007 Rival 1x D1 DUB WIDE 175

11.6218.054.005 T-TYPE 34T Direct Mount 3mm Offset

Just to be a punk, and have this bike look it’s very best, I left out any option for cable actuated rear shifting. Since the T-Type is currently only wireless, this made sense.. if I stick with it. Only the future will answer this. Still, I’d prefer a cable option for the T-Type and hope that one is released in the next model year.

Setup:

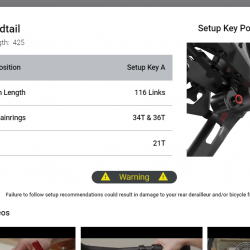

This T-Type was my first time actually setting up a SRAM AXS system and doing it with a hacked frame and drivetrain configuration made that even more special. It sucked to have to be online and signed in to have the app function in a meaningful way. I was unimpressed out of the gate just looking at my phone. Offline use should be easy.

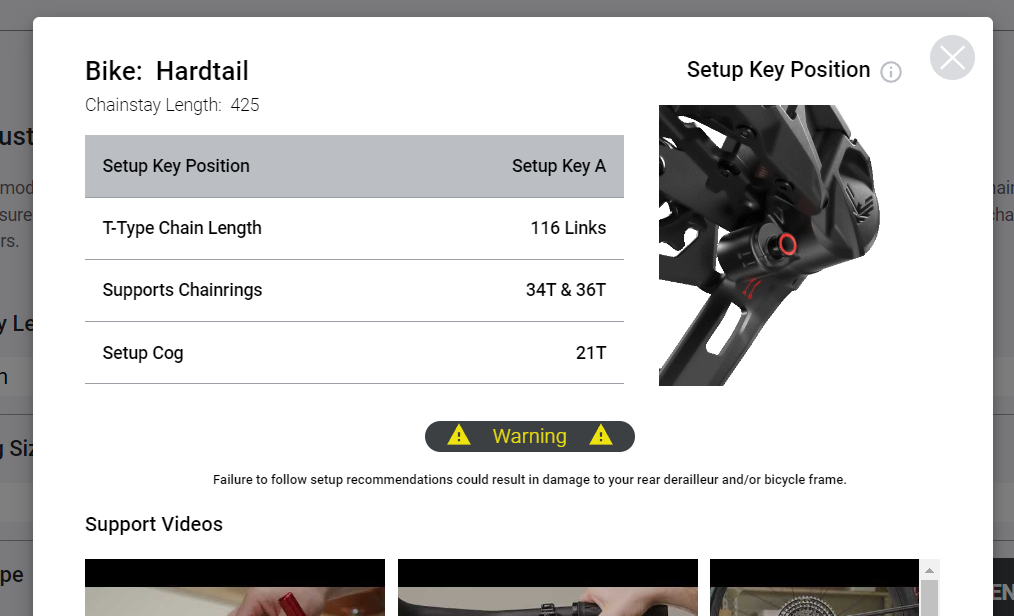

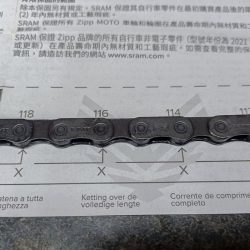

Since my frame has a 410mm rear center and is a hardtail (Key A), I had a real problem, the chain length calculators only go down to 425mm!?! Huh? This is a trail bike. Trail bikes have fairly short rears and 425mm is on the long side. Even my wife has 405mm rear center on her mountain bike. I played with the calculators and found that if I had a 425mm rear and a 30T ring, I should be on a 114 link chain. Extrapolating, with my 410mm rear and a 34T ring, I should be roughly equivalent.

To be safe, I did set up with the 116 link chain that the system had defaulted to first. It was pretty bad. Moving to the 114 link chain was a big improvement. I’m waiting on more information on this as I ask around.

The drivetrain ended up with perfect chain line in gear 7 (21T) and my 51mm chain line crankset. This was incredible news. I like to bias some to the inside of the cassette for improved climbing efficiency. Just to the left of center keeps with that. I’m expecting things to go well. THIS IS IMPORTANT INFORMATION! If anything odd is happening, it’s that in the top few gears the chain make bobble slightly while back pedaling. I don’t know if that would happen otherwise but I see it on my stand.

Still, I feel that if I was working with commodity frame in a commodity configuration, this drivetrain would have dropped in without a care and worked great right off, as many people have said.

As I’ve been having some issues with braking recently, I decided to give the new CODE brakes a try with 180mm diameter 2.0mm thick rotors. If this doesn’t work, I’m going to have to get a bit more drastic. My fingers are crossed here.

The stock adjustment ring on the Rival crank was exchanged for a Cane Creek aluminum type. This was a little extravagant but made me feel pro as fine tuning setups are very difficult with plastic threads.

I’m trying Wolf Tooth’s new ReMote Pro dropper lever. It’s a huge improvement over past offerings. I hope it works well over time. Still, they failed to fix the adjustment barrel that I’ve communicated to them about.

Setting up the rear brake caliper was a new issue. The last time that I did this I used a 40 degree translation to the FM160, as that was long before the Shimano and SRAM specifications for FM160 were established. With the SRAM 30.5 degree translation that I’m using, the commercial adapters aren’t close to working. Looking for optimal fit led me to use a FM140/PM140 commercial adapter with 10mm spacers. It worked in a pinch but I’m going to have to make some proper adapters. This seems like such an obvious issue that someone else would have solved but it hasn’t so I’m going to have to.

2023-06-16, Shakedown #1, Tamarancho

I met up with Brian for an easy loop at the ranch. I wanted to slowly push into what this bike can do and I have a couple of things in the back of my head that I’m thinking about.

The right grip needed to be tightened slightly, the derailleur trim needed some fussing, and the rear tire was slow leaking. Simple stuff. Otherwise the bike was solid and silent.

I’m wondering if 16 degrees of handlebar sweep was a little much. 14 degrees seemed like it was too little. If only there was something right in between…. I’ll keep riding it how it is but this is rolling in my mind.

The 75.5 degree ESTA felt ok but was taking away a nice slightly stretched feeling when pedaling. It’s shortening the cockpit more than I would like. It was better on the climbs. It’s also raising me up on the bike. I feel taller on the bike. It feels silly.

The ergonomics of the shifter pod suck. It’s really hard to get in the correct location when the brake lever is correctly set. I have to disconnect my hand to reach over to shift. I’m going to try the matchmaker mount to see if that gives me something more. To be fair, I’m also trying to shift like my old shifter. As time goes by, we’ll see what happens in this space.

2023-06-17, Shakedown #2, Lake Loop

It’s a busy weekend so I’m squeezing in quick rides. Windy and I rode up to the lakes before we left for a couple of parties.

We did a lot more traversing than on the first ride. Some pavement and fire road. I really noticed the compromise of the saddle location and the increased weight on my hands. While the bike is better on climbs, it’s worse on the traverse. I’m going to keep my eye on this and see how my perspective changes. I’m definitely at the steepest end of what I can handle in my environment.

2023-06-19, Setup Modification

I got into the shop on Monday and produced a proper adapter for the caliper on the manual mill and die grinder. It isn’t pretty but it’s correct to spec. It bolted right up and required almost no fuss to have in perfect placement. It’s nice when all the math and modeling turns into something good.

I’ll have some very fancy versions of this produced while I’m on a road trip. More on this later.

2023-06-21, Setup Modification

I put off discussion of the trim adjustment of the system until I had enough time and experience with it. I had it set at 1:14 or, the furthest inboard. I feel like I could use one or two more clicks inboard more to get everything working perfect.

There is some fuss in the system that could be due to the chainstay length being so small, inability to ‘know’ the correct chain length, and the narrow chainline that I’m using. What part of that pushing things is a question.

I’m hoping a firmware update gives a few more trim clicks of range and the powers that be help folks with ‘out of spec’ chainstay lengths arrive at the right chain length.

So I changed the XDr spacer on my hub from 1.8mm to 2mm to push the cassette outboard, effectively producing more range where I need it. Now, I’m at 2:14 and the system is working pretty good. More work on this over time is in order.