I recently came across an interesting situation with pedals and I figured that this would be a good opportunity to look into some fun topics: blind bearing extraction, slide hammers, and strange bearing sizes.

I have a set of Spank Spike pedals. I don’t use them regularly but will on flow trail or jump park days. They are pretty nice pedals and I appreciate the good design. They were some of the nicest pedals on the market until the Race Face Atlas pedals showed up. However, the bearings needed some work so I got the replacement parts.

Online video and service instructions conveniently leave out service to the main bearing. Why? Because it’s not simple, and as we’ve learned, Bicycle People are simple. The lack of mechanical competency in the bicycle world is astounding.

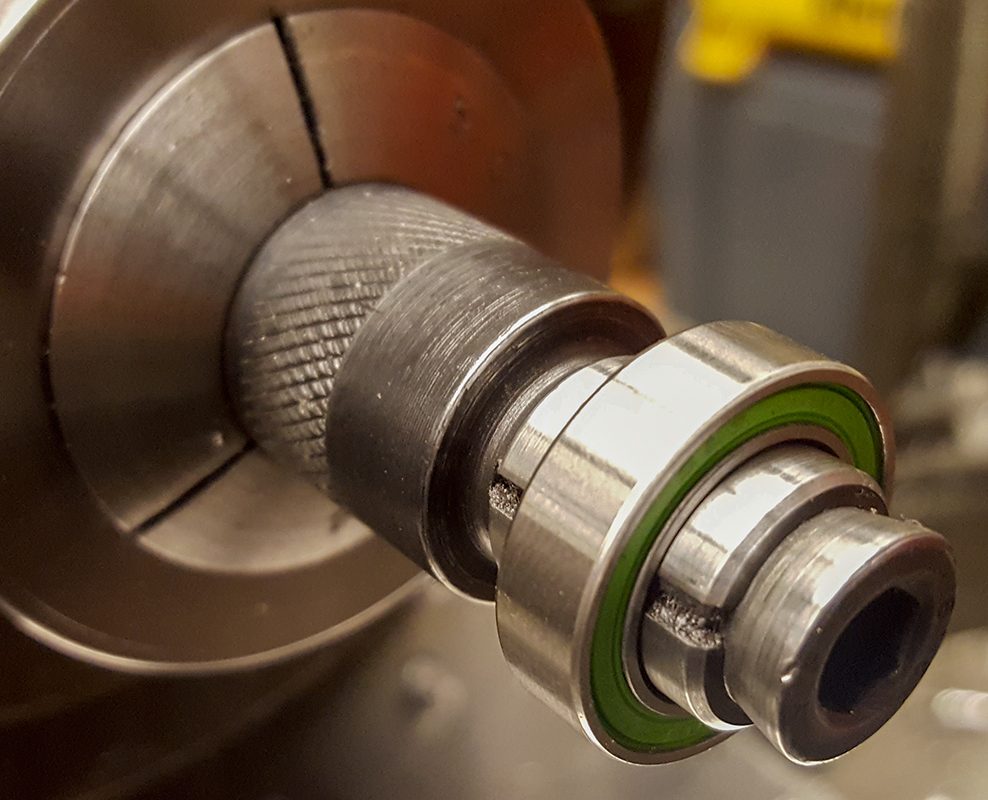

The main bearing is a full complement type and is marked 14226V-2RS and from S&S in China. 14mm ID, 22mm OD, 6mm WD. It’s an unusual size. I did not find it listed as a product by any bearing manufacturer in the world. The outer edge of the inner race is about 16mm. The bearings I pulled out had a tan shield and the new bearings had a green shield. The Outer seals were metal backed (black) whereas the new model seals are not (green).

The big issue, the instructions note that a special tool from The Gravity Cartel is required for removal of the bearings. I contacted them directly (out of curiosity) and after some digging around they mentioned a tool similar to the OTC 1174 that I discuss below is what they use. It’s a costly tool for novice mechanics might not be able to invest in.

Try as I might, I wasn’t able to find any specific blind 14mm extractors on the market — for anything. Across all industries, 14mm ID bearings are extremely rare. I couldn’t have imagined that this would be such a rare item.

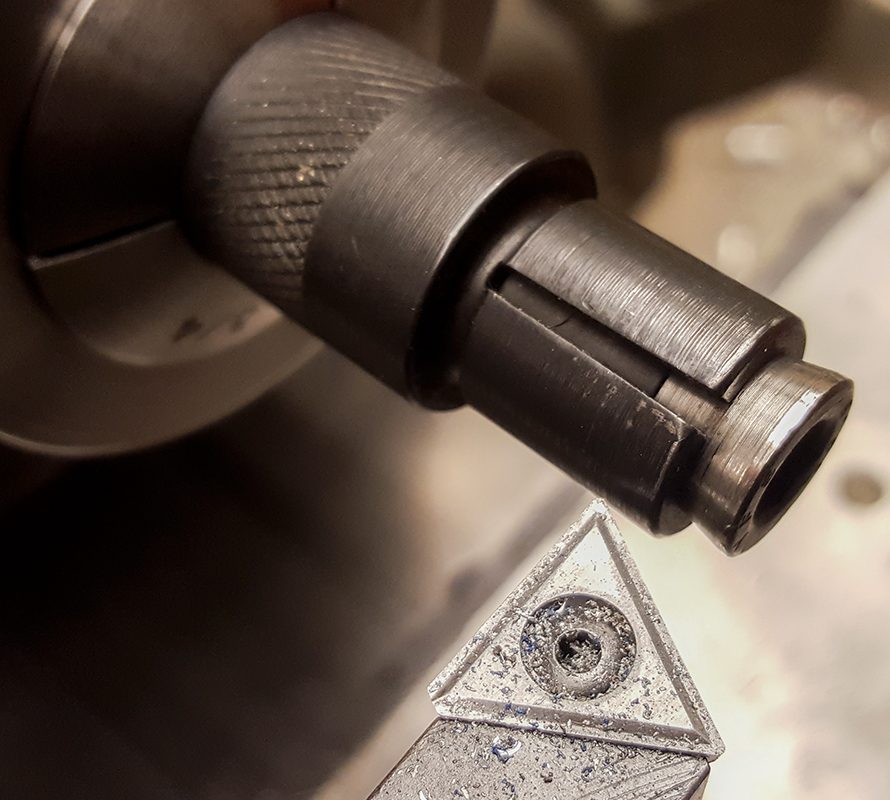

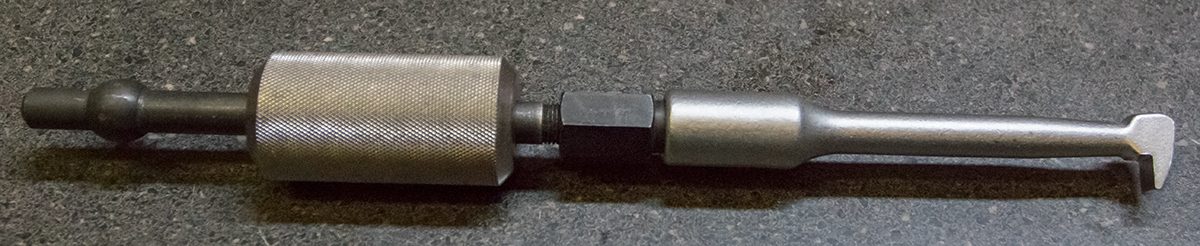

I have a Motion Pro 15mm Extractor (C08-292D) and a Wheels Manufacturing 15mm Extractor (6002-EXT). Since the Wheels extractor is cheap and easy for me to replace, I’ve modified that to work with 14mm. A few quick precise passes on the lathe and it fit a 14mm bearing snugly.

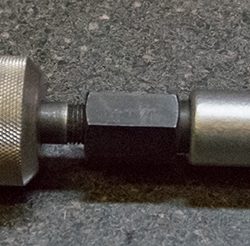

I next have to adapt this to a small slide hammer, OTC 5028. This will be accomplished via the OTC Tools 8113 8×1.25mm threaded adapter, a M8 coupling nut, and a pair of M8 jam nuts.

A note about slide hammers. It’s important to have a slide hammer in your tool chest that is threaded 5/8″-18 or 1/2″-20. OTC supplies most of the automotive and industrial suppliers in the USA with high quality tools. Having this type ensures you have access to their vast catalog of ID and OD pullers. Saving money on a hammer with a lame thread is really just a waste of money as you will be stuck buying new hammers depending on the attachments you use.

I like this tool setup because it gives a lot of support around the bearing to (hopefully) minimize the chances of the delicate bearing breaking apart. A few funny adapters make it look clumsy. A custom 10x1mm to 8×1.25mm couple nut would clean things up considerably.

There are other options:

A threaded pass through plate.

If room is provided for this solution, a pass through plate with a thread in it can work with a slide hammer by banging the other side of the bearing instead of the inner diameter. Some quick math will provide the size. Since we tend to know the thickness of material we have clearance for and that will handle the loads, we calculate the width that will allow the plate to pass the ID of the bearing.

There are a few ways to cut this part but this is one of the nicer and easier ways if you are working with a lathe. Once the round parts are cut, simply cut one side on the mill or grinder to get to the needed width. This is simple and has an odd trick look to it. There are far fancier ways of doing all this but I’ve shown the basic version here for the 14mm size I need in this bearing.

I can then thread the OTC Tools 8000 1/4″ threaded adapter into the plate and use with my slide hammer.

The jaw puller:

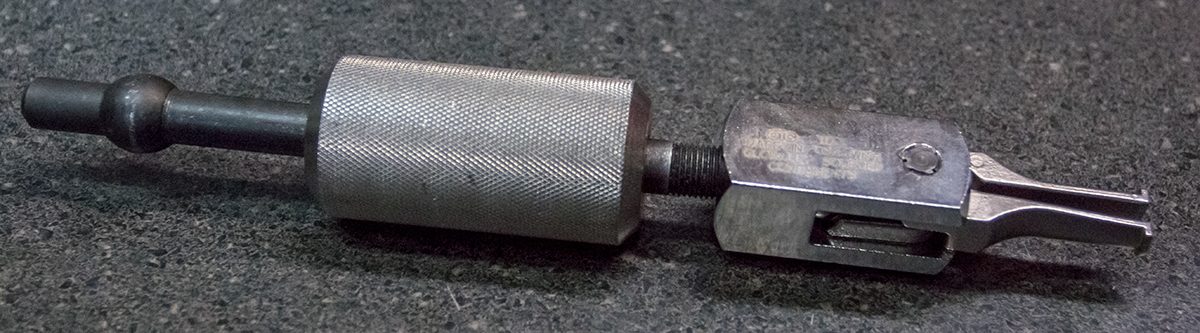

One tool in this realm that is really nice and does work with a bearing this small is the OTC 1174. I wouldn’t want to man-handle it (heavier duty versions exist) but for fine level work it’s a nice toy.

The hook.

Last but not least, a simple hook can bail out a situation. This is a neanderthal solution but in some cases, it’s perfect.

Simple.