This is a big deal for me.

For years, I’ve been looking for a way to mark my bikes. The careful observer may have noticed that close to none of my bicycles have had any identifying marks on them other than the fingerprints of my design aesthetic. No decals. no logos. No marks. Why? Because I’m not selling anything. This is all about me. It’s not about you. I’m not worried that you don’t know what I’m on from 40 feet away. My art. I’m not a branding guy. I don’t like branding folk. Marketing is fucking bullshit and I didn’t want to be made to play the game as defined by others.

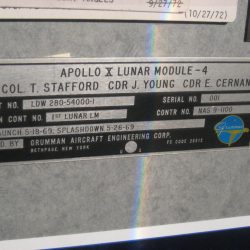

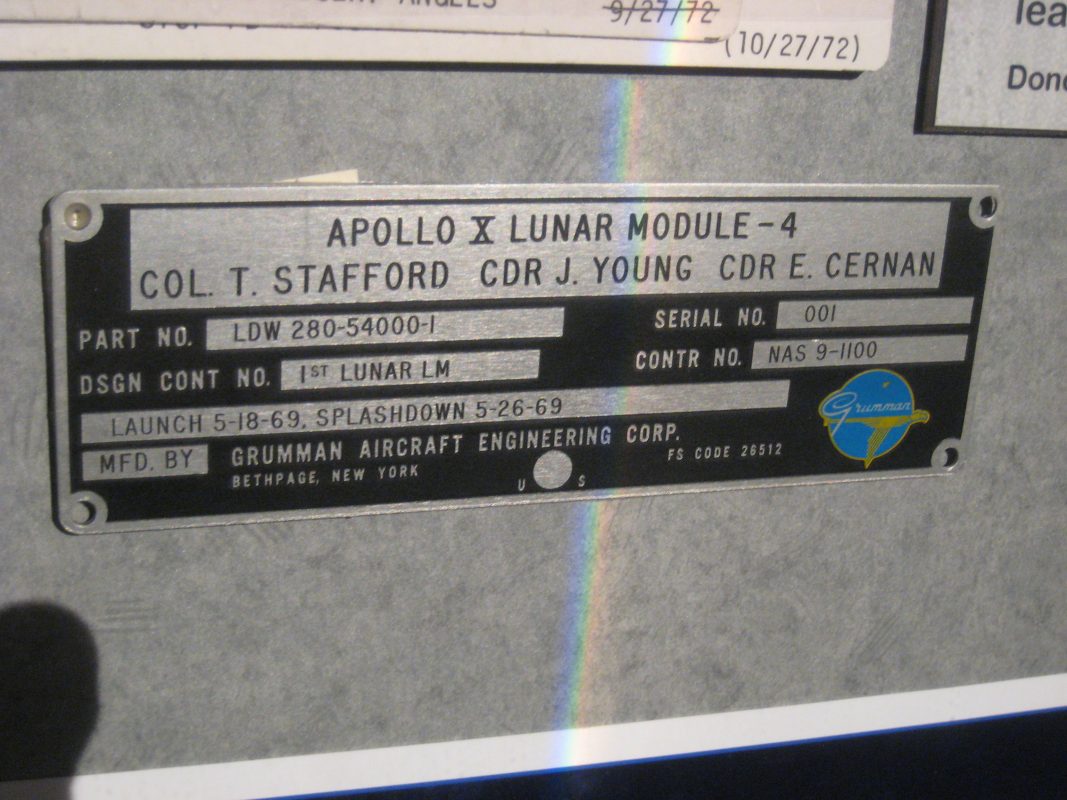

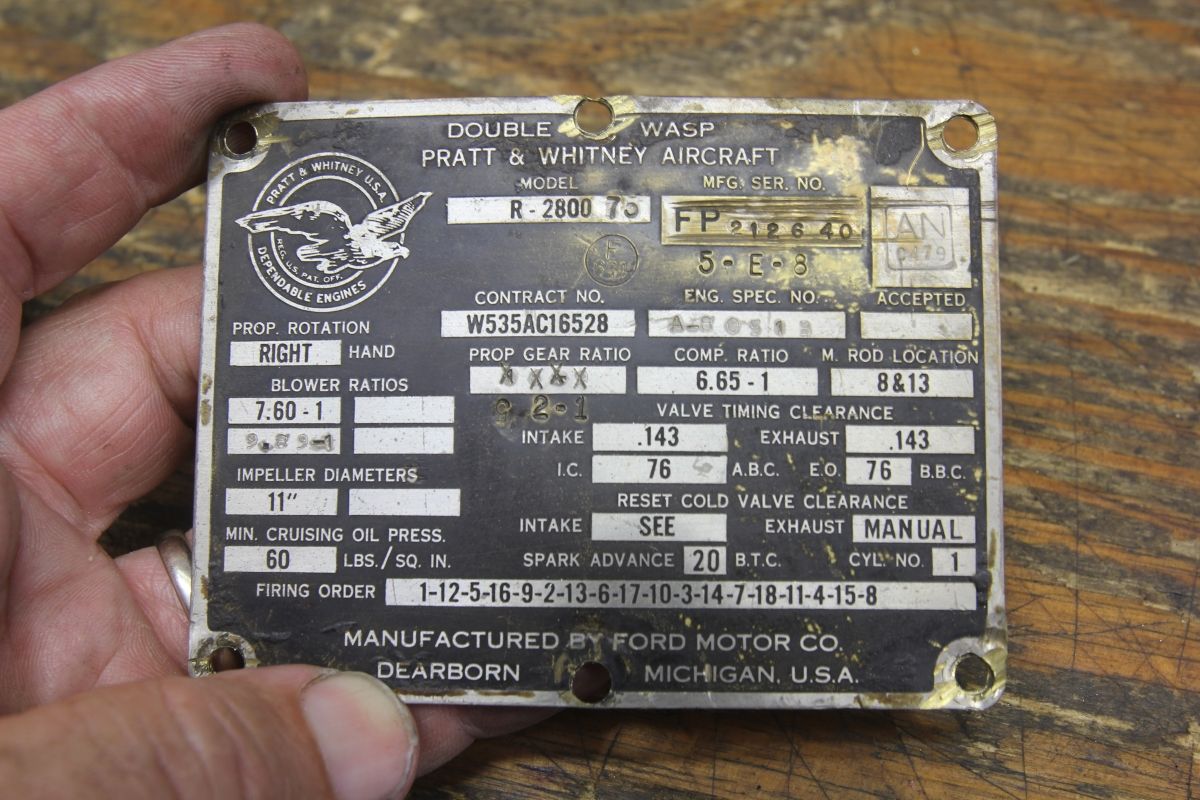

So, a data plate. Like any other industrial guy, I love a good data plate. They solve problems. They tell me what I need to know. Everything of real value has one. They need to have one. Is my bike any different that a B-17 or an Apollo X Lunar Module? No. It’s the same.

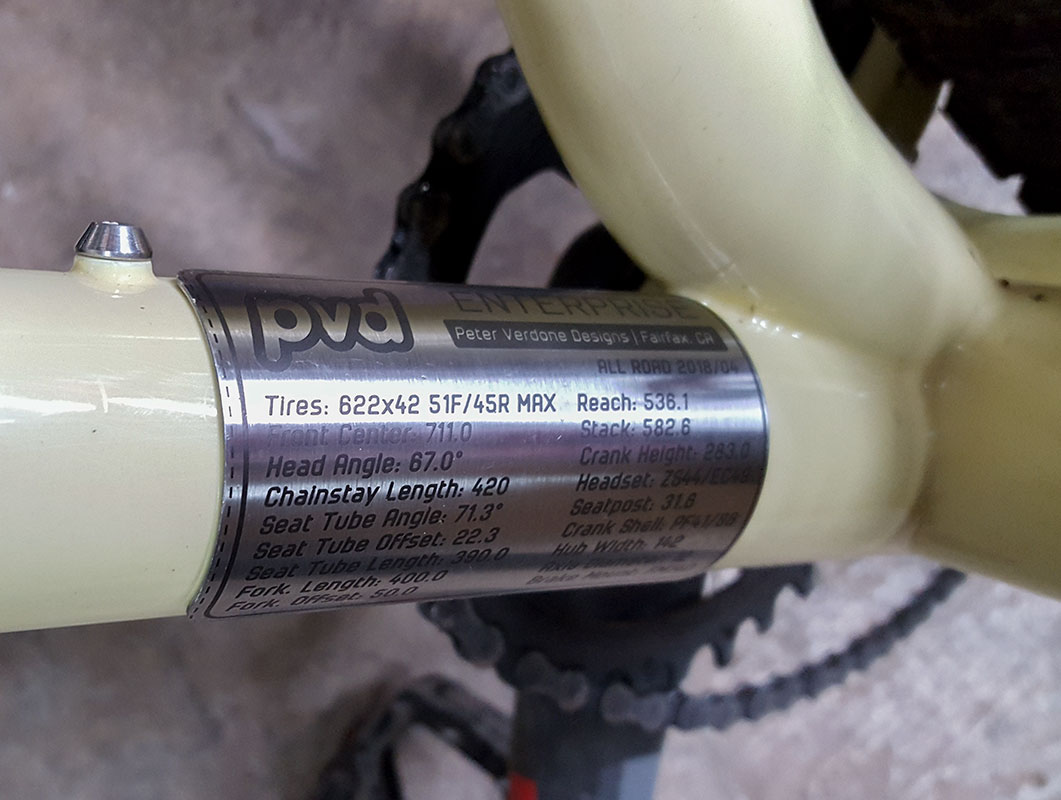

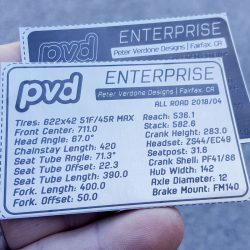

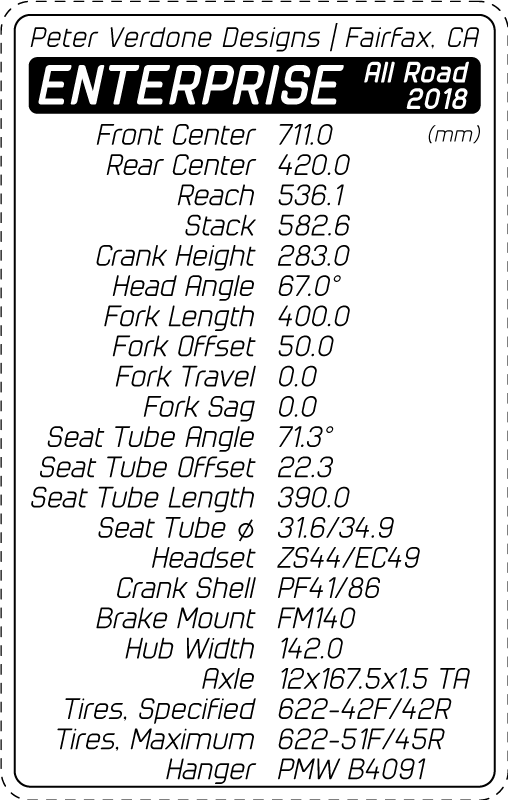

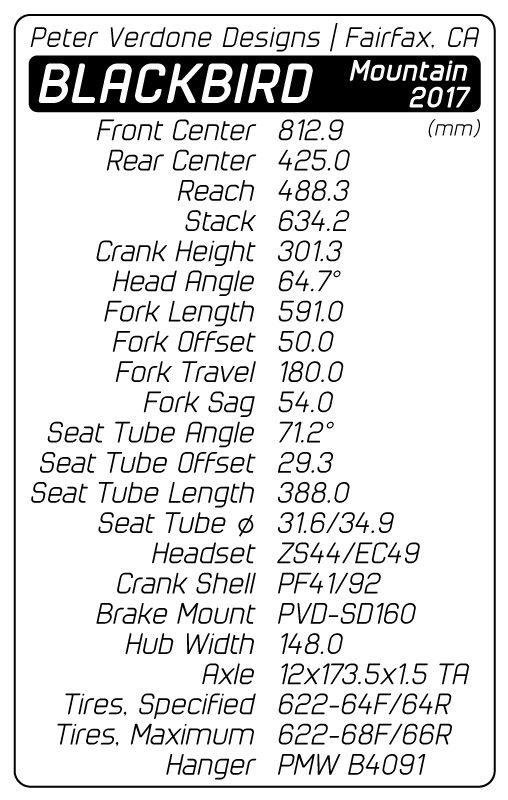

So I went down the worm hole to make my own. The design goal wasn’t to make a novelty plate or hark back on anything. It was to be a real data plate. To convey information important to stay with the machine. To solve problems.

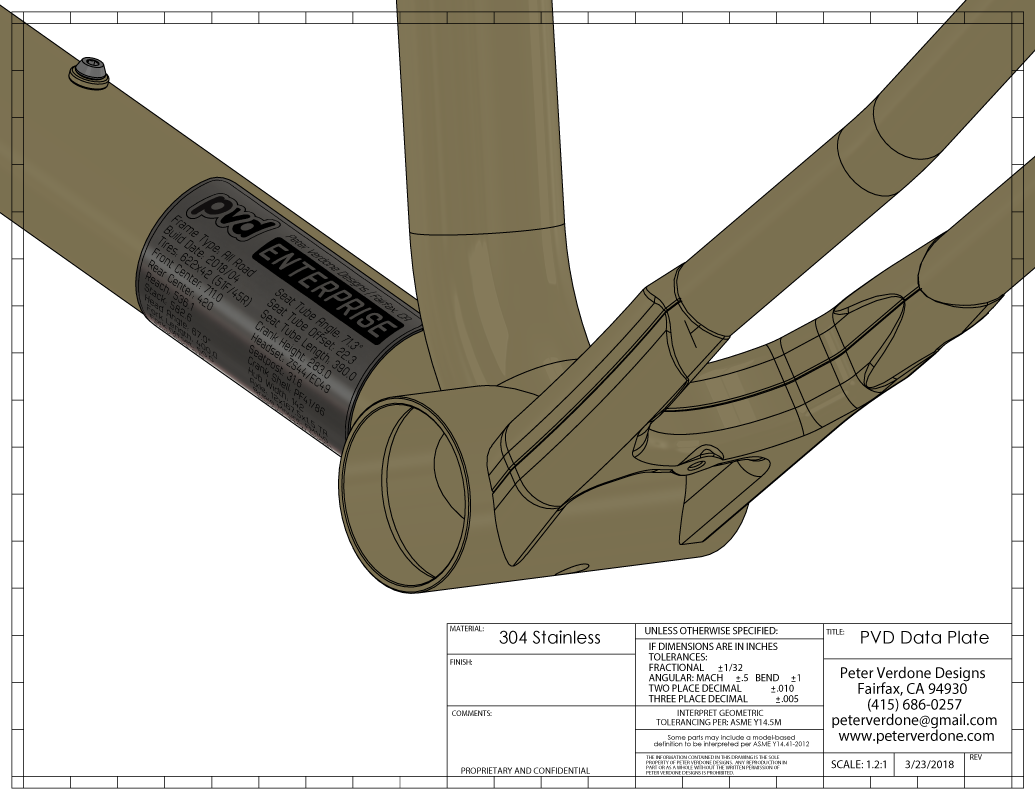

A good bit of time was spent getting the information that I felt was important onto the plate in a sensible way. What information have I needed when working on a bike? What information would a rider need to accurately construct the bike in a fit or CAD environment? Would it be clear that I made the bike? Of course, would it carry the name of the bike? I did my best so far. The graphic continues to change. This is all in testing phase but the results still look amazing.

Getting useful information onto a bike isn’t a new idea. Some companies have started to provide a bit of information on their bikes, like Transition and Kona. I’m just going to take the concept a few steps further to the logical end. A real data plate with everything you need…on the bike.

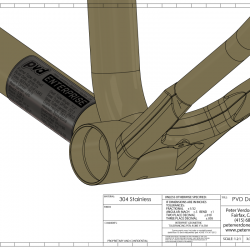

The test plates were cut from 0.030″ 304 stainless steel to 2.0″ x 3.0″ pieces. Several plates were marked in a few different ways. We tested the marking and found that it was just slightly harder and stronger than the material that it’s on. So I trust the marking to last. Then a bending protocol was tested to get the plate into the shape of the 1.500″ diameter tube.

I believe that the plates are a little too thick now. I’m sure that they could go down to 0.020″ or 0.015″. I just need some more testing on this and working out the finish. I also may look to move the size to 2.0″ x 3.5″. It may be a little large on the bike but the other uses of this size makes it attractive.

VHB tape will probably be used to fasten the plate. I’ve had some suggestions for screws or rivets. I think tape will be fine and allow for easy repaints. VHB is very thin and very strong. It will do the job.

Now, I look into sourcing a better material and deciding on laser cut or stamped plates. Then some special bending fixtures for best results.

Tooling with targets.