At Eurobike a few weeks ago, SRAM made public their Universal derailleur hanger (UDH) concept. There was a bit of hype from the marketing shills. None of it made much sense. The problems that all of the marketing people were saying it solved really aren’t legitimate problems or serious consumer problems. I didn’t think much of it. It seemed like something nobody really needed. I talked some trash. So much hype. So much talk of problems we don’t have.

Then I came across Zach Overholt’s article in Bikerumor, SRAM’s universal hanger concept could make coaxial mounted (hangerless) derailleurs a thing (again), form September 16, 2019. I’ve got to hand it to Zach. Nobody else in the marketing industry had made any mention of an oncoming coaxial derailleur and it’s connection to the UDH platform. A trojan horse. While everyone was talking about bent hangers, replacing hangers, and $15 cost, Zach showed me what was really going on. Thanks to Zach for rising above the others!

It was instantly obvious. The SRAM UDH is just a tool that SRAM is using to get inertia up a few years ahead of the release of the coax derailleur so that the market exists for the product. One or two years of compatible product on the market is important if you want to sell something.

I’m all over this. I’ve got a few UDH parts (00.7918.093.000) in hand. The hanger, bolt, and washer are constructed from aluminum, contrary to some reports. Of course, I’m going to design a dropout using this system.

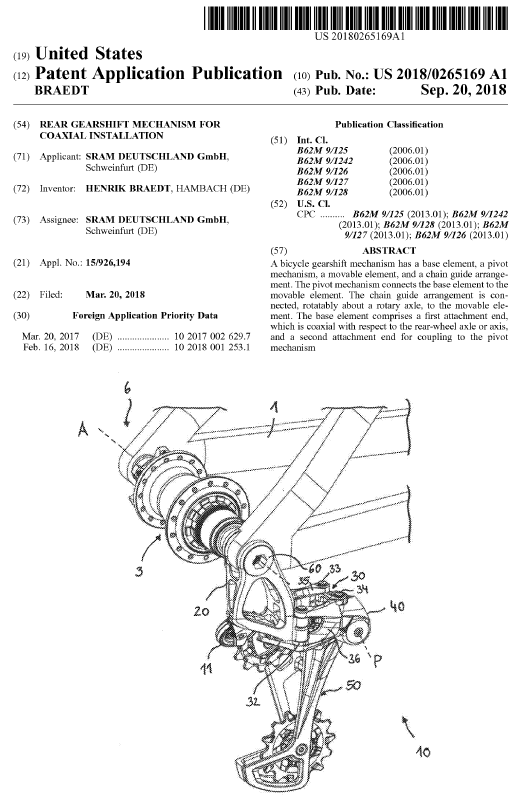

The patent: dated September 20, 2018: Rear gearshift mechanism for coaxial installation (US20180265169A1) US 2018 / 0265169 A1. This is where all of this is going. Getting to a new way of co-axially mounting rear derailleurs.

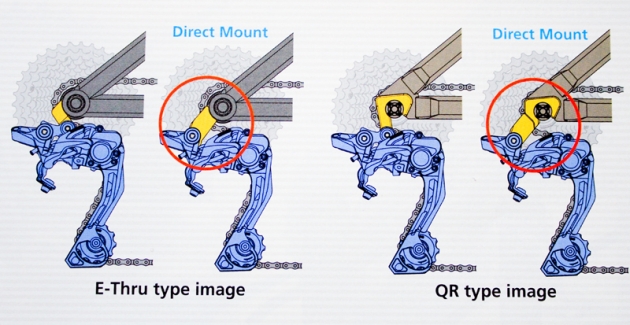

Obviously, we all remember that Shimano has tried to do a coax derailleur in the past, the Saint M800-RD 9-speed back in 2003, a coaxial mounted derailleur that was part of Shimano’s first real downhill group (even though there were XTR-DH parts floating around and a few ‘prototype’ parts including #airlines). It was very cool.

There were good things about this derailleur but inconsistencies in frame design, sparce thru-axle adoption at the time, few compatible 10mm TA hubs, and that it was part of an extremely pricey and heavy downhill group meant that few people were interested in it. Shimano killed this off fairly quickly. SRAM was also doing a lot of marking work at the time to get downhillers to use their drivetrain parts.

Then, in 2008, Shimano introduced the RD-M772 (9-speed) and with it, the Shadow mount, a transitional design that was intended to lead to the adoption of the Shimano DRD Hanger use. They would get this out in the market, then change the frame mount (2012). It was a good strategy.

This was an excellent system and I (and many that I knew) was on board with in my designs. It worked with existing wheels, it was robust, it gave us lots of room to load wheels, it worked great! So what went wrong? Why didn’t it take off?

2012, was about the time that Shimano was rolling out the DRD frame specifications and getting OEMs on board, but it was also the year of the release of SRAM XX1. This was the beginning of the end for Shimano off-road drive train dominance. Just as Shimano was starting a real push for DRD, SRAM was tipping the whole ecosystem upside down. Since XX1’s introduction, SRAM has only improved their system, now 12-speed, robust, and cheap, while Shimano has treaded water. SRAM became the only serious choice for off-road shifting. Since DRD was proprietary, you didn’t want it to run SRAM. This is what killed DRD.

So what’s so good about UDH now? Well, there are a few factors that set this up for success.

- SRAM has legitimate dominance in the drive-train market, especially in off-road

- Nearly all but economy bikes are using thru-axles now

- Most rear wheels on the market have 12mm thru-axle hubs

- Rear thru-axles on almost all bikes are the same diameter, 12mm

- The design of the UDH/coax derailleur system looks excellent

- Roll-out is strategically sensible.

It really is time to ditch the terrible way we mount derailleur systems to bikes. I’m excited that SRAM is making this move, especially when they have such a good system in place for adopting it. I’m really hoping that this sticks.

The part itself is a composite. The mechanical component is aluminum while the body is an injected plastic. It’s well designed and looks nice. What is very nice about the design is how simple the frame side is; basically a bore and a round face with a rotational stop.

The frame specification for this system is soon to be released to the market. Most large OEMs have had access to it and some 2020 frames are being spec’d with the part. I’m still waiting on the official data for design but will be modeling the parts that I get in hand on Wednesday. Hopefully, good options exist for how this all works in real life.

Note: The 2018 patent filing mentions the adaptability of the system for use with 15 mm axles rather than 12 mm. I believe that this may come into play for larger electric bicycles but not something to be concerned about in current chassis design.

[ 0097 ] The described gearshift mechanism designs permit both radial centering of the base element on the adapter, more specifically on the bolt foot of the adapter, and radial centering of the base element directly on a centering surface of the thru axle. This has the advantage that the same base element can be used with thru axles of different diameter . The gearshift mechanism can remain largely unchanged. Only the adapter, in particular the bolt, for the fastening of the gearshift mechanism to the frame has to be adapted to the external dimensions of the respectively used thru axle. Common external diameters for the thru axles are 12 mm and 15 mm. This embodiment also enables the same hub arrangement to be adapted quickly and inexpensively to different conditions merely by exchanging the thru axle. For example, to increase the stiffness of the rear – wheel axle arrangement, a 12 mm thru axle can be replaced with a 15 mm thru axle. Different wall thickness configurations of the 15 mm thru axle furthermore permit adaptation to particularly lightweight or particularly rigid rear – wheel axle arrangements.