Now that I’m back from my Whistler trip and ready to replace the brutalized rim of the rear wheel on my bike, I’m looking into the spoke lengths needed to do the job.

The Chromag BA30 rim has a nipple stagger of about 5.2mm, 2.6mm to either side. This threw a wrench into my usual calculators that don’t have provisions for this. The QBP calculator will just do an offset to one side, others not at all.

So, we move to FreeSpoke, by Karl Stoerzinger. It’s a very nice online calculator and a derivation of Spocalc. As always, mileage may vary and ERD measurements are crucial to understand. It’s also worth looking into the root of the expressions used: HERE

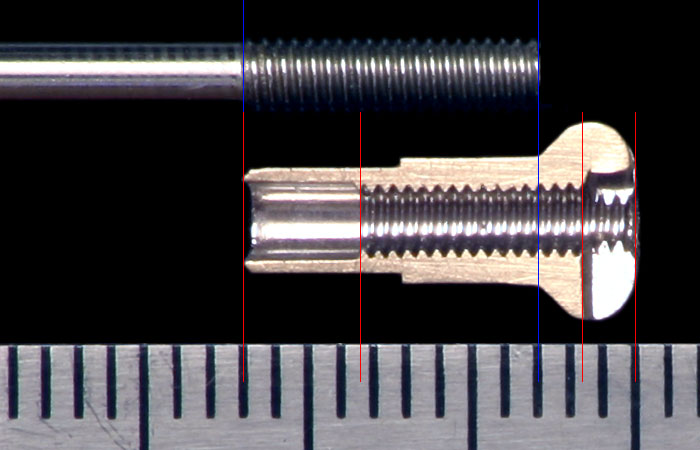

Correct ERD measurement location via Freespok:

Another very interesting calculator is Eric Menze’s WheelSpoking. There’s a bit to play with there.

The math:

ND Spoke length = SQRT((ND flange diameter/2*SIN(2*PI()*Cross number/(Spoke holes/2)))^2 + (ERD/2-((ND flange diameter/2)*COS(2*PI()*Center to ND flange/(Spoke holes/2))))^2 + (Center to ND flange – Rim drilling offset)^2) – Spoke hole diameter/2

It looks like many online calculators will subtract 0.25mm (QBP) or 0.30mm (NOX) from the theoretical values. That, expectedly, is to make up for some settling of the parts. It may be wise to subtract up to 0.5mm if there are concerns about great adjustments.

Onyx MTB BOOST CL XD-148/12mm Thru-bolt Rear Hub

Hub Center To Flange Center, Non-Drive Side (mm): 36.9

Hub Center To Flange Center, Drive Side (mm): 22.92

Axle Width (mm): 148

Spoke Hole Circle Diameter, Drive Side (mm): 50

Spoke Hole Circle Diameter, Non-Drive Side (mm): 50

Spoke Hole Diameter (mm): 2.5

Spoke Hole Count: 32

Chromag BA30 Rim:

ERD (mm): 604

Stagger (mm): 2.6

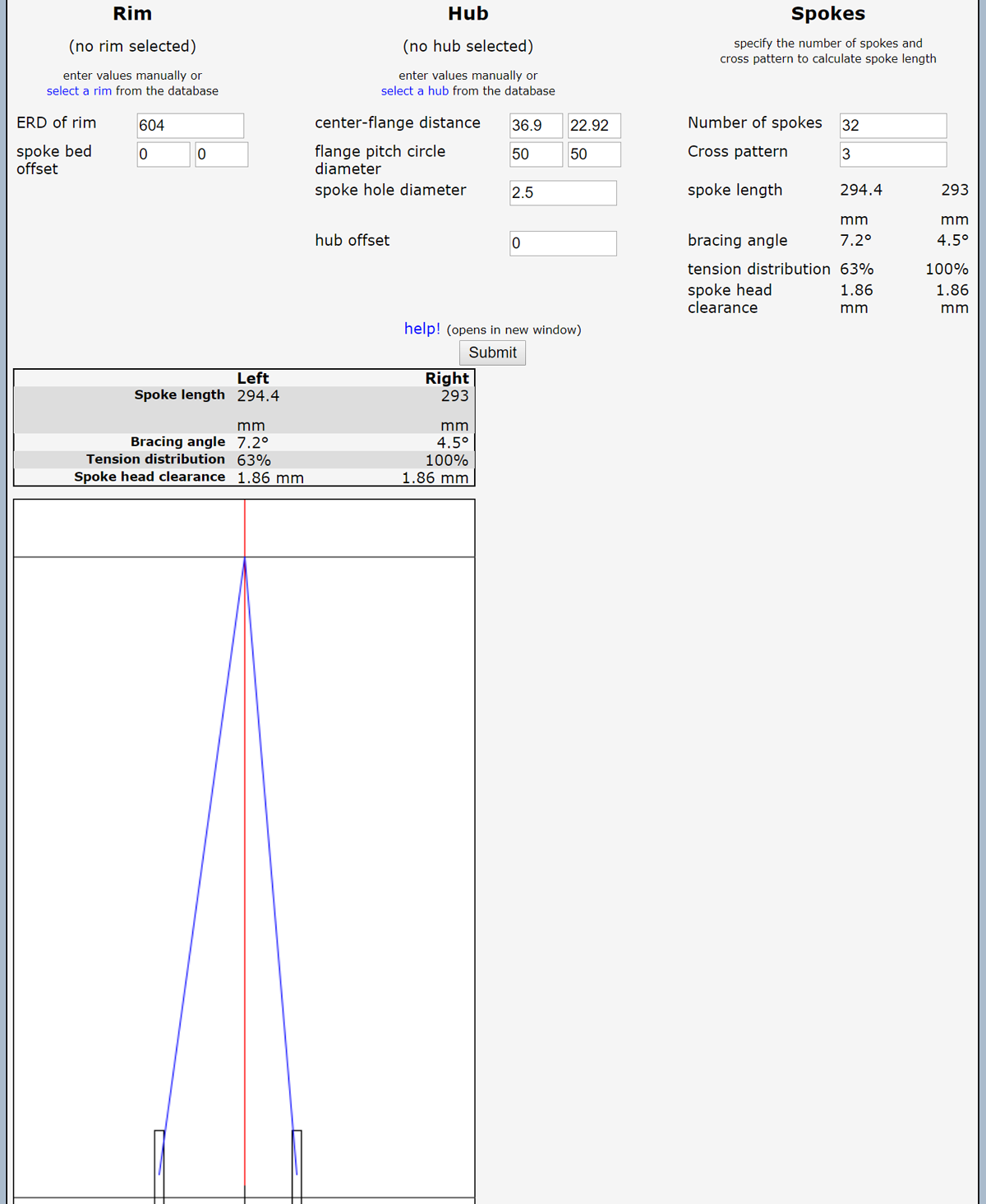

Without accounting for the stagger, we get this result:

This returns spoke lengths of 294.4(ND) and 293.0(D). But this is not correct as the rim is drilled staggered. We want our math to be as good as we can.

So we shift the nipples on the rim:

Now, it returns spoke lengths of 294.1(ND) and 292.8(D). A change of 0.3 and 0.2 millimeters respectively. Notice also that the spoke angle is decreased 0.5 degrees on both sides. This reduction in lateral tension made up for by the increased support of the rims structure.

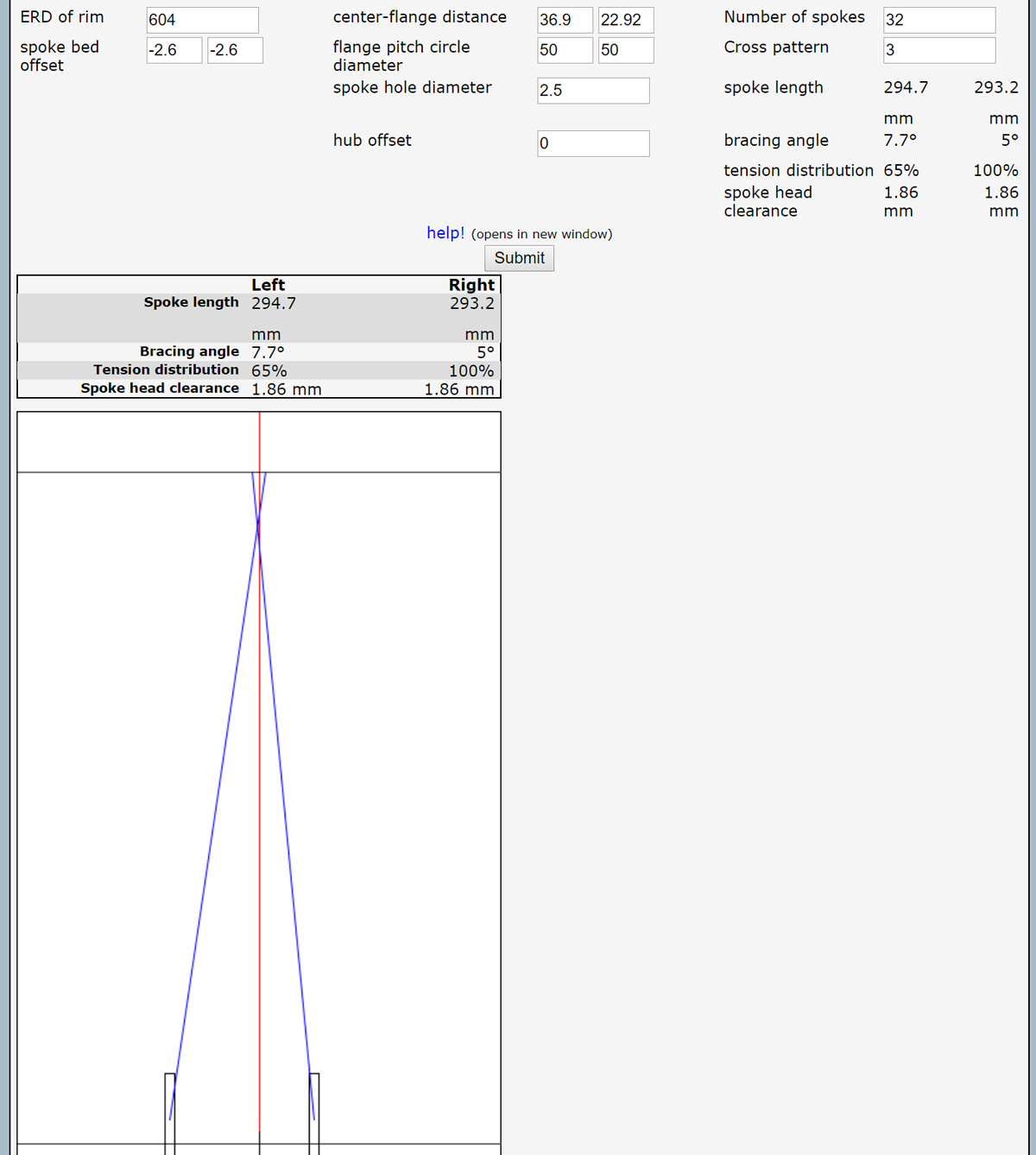

Here’s another option:

This time, we walk the spokes across the rim to the opposite side. Spoke lengths of 294.7(ND) and 293.2(D). We have now increased the spoke angle by a full degree! That’s a 25% angle increase on the drive side and 15% on the non-drive side. The structure of the rim is still improved by the stagger. This is pretty cool and a 5% increase in tension on the non-drive side compared to the drive side over the under-crossed layout.

I’m thinking of going this route for these burly 29er wheels.

What problems will be faced? There will be increased stresses at each end of the spoke as the rim isn’t optimized for this pull and the j-bend has an additional degree of bend to deal with.

Haven’t seen this before? Take a look at the wheels from this 2009 BMW R1200GS. These are some very fancy rims engineered by one of the worlds finest motorcycle brands. Three problems were addressed by this solution: making a real tubeless rim for a spoked wheel, spoke replacement with the wheel on the bike and tire in place, and increased lateral stiffness. It’s not the lightest wheel in the world but it’s definitely very cool.