It’s funny to post this now as I am currently engaged. Ha.

Anyway….

Bicycle ‘mechanics’ are generally very inexperienced riders. They spends their days in workshops talking trash and theorizing about this and that. They wax their beards and go out for beers with their boyfriends after work. Late at night, they gaze into the blue glow of their screens to see what has happened on some message board about the artisanal use of cork bar tape. Rarely do they ever get out on a real ride or test the limits of current technology. Even more, they don’t get enough real experience riding to start seeing and feeling the subtle differences that make one bike work differently than another.

Because of this they will have views of how parts should be chosen or how bicycles should be put together that are less informed by real riding and more based on what Sheldon Brown said in 1997. It’s painful. They’re disconnected.

Recently, the topic of hub engagement came up in discussion among bicycle ‘mechanics’ online. I noted that a hub with 32 points of engagement isn’t really that valuable as a high performance hub. Others said; engagement is over rated and not a priority in hub choice when compared to weight. Mostly, these folks were enamored of how light the particular hub was rather than how useful it is. Weight is a parameter in making choices in bicycle parts but far less important than most people think. Classic example of supplanting a scale for reason. I can’t stand that.

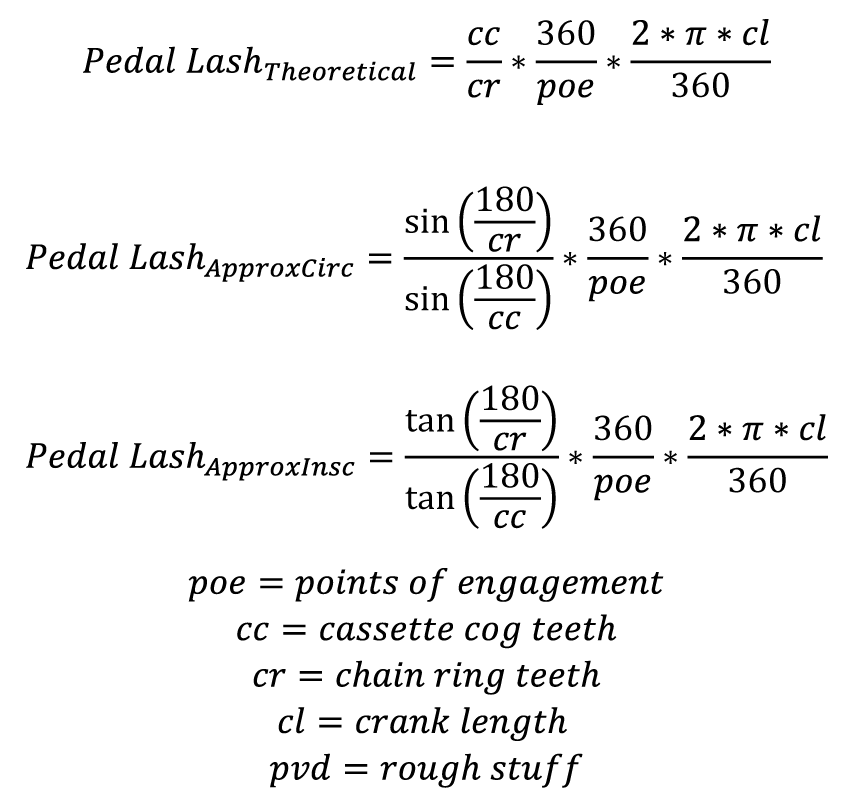

Here’s the problem, math.

The formulas above tell us a lot about the rear hub on a bicycle and what it’s doing. The Theoretical formula is a bit easier to use but has the built in problem in that it assumes that cogs and chainrings are round, which they are not. Chainrings and cogs are polygonally shaped. Depending on the alignment of the parts at any instant, there will be a bi-directional pulse of a small sinusoidal amount translating the cog movement to the chainring and it’s pickup.The ApproxCirc formula treats the cogs and rings as polygons and references the circumscribing radii of the two gears. ApproxInsc compares the inscribed radii of the two gears. None of this really matters at the scale that we are looking at. Reality will still depend on a few other variables as well and the difference between the approximations we’re looking at is only a few tenths of a millimeter.

Let’s say we have a hub with 32 points of engagement (like the hub in question). Also, a crank length of 175mm, a cassette cog of 42t, chain ring of 30t, and of course, a chain pitch of 12.7mm. The pedal lash in that system will be 48.1mm. That huge almost 2″ of free throw while (assuming the gearing) everything is on the line. This also assumes that the bike is at a complete standstill. As velocity increases, the free throw is magnified.

Bump that up to a 54 poe mechanism, like a high end DT Swiss hub will have, and your lash goes down to 28.5mm. 59% the lash of the other hub (of course, proportional to the engagements). Still, that is almost 20mm less pedal movement before driving starts.

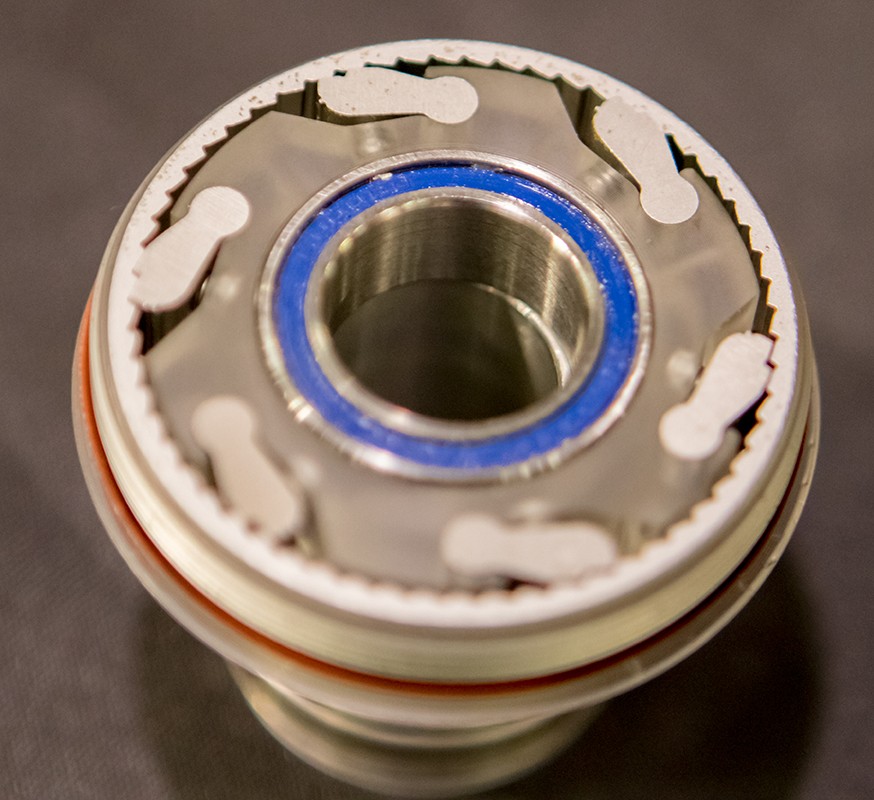

The DT Swiss 54 isn’t even that high of an engagement compared to what Industry Nine (120 & 690), Profile (204, but garbage), Kappius (240), Chris King (72, meh), Hadley (72, meh), Onyx (NI, dope), True Precision Stealth (NI, junk).

I’m currently liking the Onyx hubs since they finally adopted the Center Lock system that I demand. With near infinite points of engagement they are serious performance tools.

This ‘opinion’ didn’t come from doing the math that I show above. It came from hundreds and hundreds of hours of trail riding using many different drive train configurations. While changing over to 1×11 drive from 2×10 drive systems I was noticing a real problem with the pedal lash creating an instability on the trail. What was working with smaller cassette cogs (32t) found issues magnified enough to be very noticeable with the new larger cogs (42t). The slash, even in the mid-range gears, was floating around so much along with the massive cassette weight tugging and snapping at it while soft pedaling or ratcheting power. The fix for that was to move to higher engagement hubs. Simple problem resolution…or at least minimized.

Even for road bikes this is important. Look at a bike with 172.5mm cranks, a 25t cassette and 39t small chainring. With 32 POE, the crank has 21.7mm of lash. With 120 POE, 5.8mm of lash. Roadies put a lot of work into getting the crispest feel and instantaneous response from their bikes. Here, a 15.9mm difference in lash is massive. Imagine what s/he would say if you offered them brakes that needed twice the pull to work, they’d laugh at you. Here, you’re optioning almost 4 times the lash and imagining it’s ok with the 32 POE. For what? A 49 gram savings (DT Swiss 180, 183g, 54 POE), the very high possibility of wheel failure, and a lot more lash. That’s not good decision making.

Drag does go up with various mechanisms and an increase in POE. Onyx goes around that problem. It’s a consideration in some places but most performance oriented riders will be pedaling in any situation where that is a real factor. There is also a different lubrication regime that a competitive race bike’s hub will see that others won’t further decreasing friction.

Of course, every sword is double edged in some way. When POE goes up very high, kickback from suspension systems can pass through to the rider even while not on power. This will translate into more thrust overall but might cause some ‘feel’ issues in certain places. Still, the faster that the bike is moving, the less this shows up.

Lesson of the day, buy high engagement hubs. It’s worth a few grams and a good investment. A Deore XT FH-M788 hub has 36 POI, your new hub should have at least that but more if you are looking for serious performance.

Also, don’t buy Italian made garbage.