This is some seriously nerdy stuff. Since I haven’t seen any folks discuss it so, once again, I have to.

I’ve just sent files to the printer for a new all-road bike for me. After most of the real work had been done, I began fine tuning and evaluating my expectations and decisions. This last bit is the really fun part of the process where changes can increase the connection between the bike and it’s mission. I looked again at the front end design. This has a large effect on the feel of the bike.

Since I’m producing my own fork, I can optimize for the geometric properties that I’m looking for. In this case, that means a 70 degree head angle paired with a 40mm offset. This produces some nice 88.9mm front wheel (mechanical) trail and 30.4mm flop when using a 622-66 tire. Remember that this bike will have a 830mm front center. Those are some pretty cool numbers for this class of bike. I might have gone with more trail (using less offset) but lightness in the feel was a goal.

I knew what my tires, head angle, and offset would be, but I wasn’t quite sure about the length of the fork yet. Rough modeling told me that I would be looking for at least a 420mm fork length to fit the 66mm tire, adding in mud clearance and the ability to use a proper fender. Since this was getting long, I started wondering; how much room would I need if I were to drop in one of the new “gravel suspension” forks in the frame? Meaning, a proper swap of one of these forks so that most of the design goals of the bike are preserved.

I don’t think that the gravel platform is advantaged much by tiny and flexible suspension forks, outside of the leaf spring designs we see in racing. Those forks are limited because of their torsional flex, and have no place on trail. In most cases, I feel that a larger volume tire is a better choice until we decide to make the jump to the 80-100mm class of proper telescoping forks. This is also well out of place with a drop handlebar.

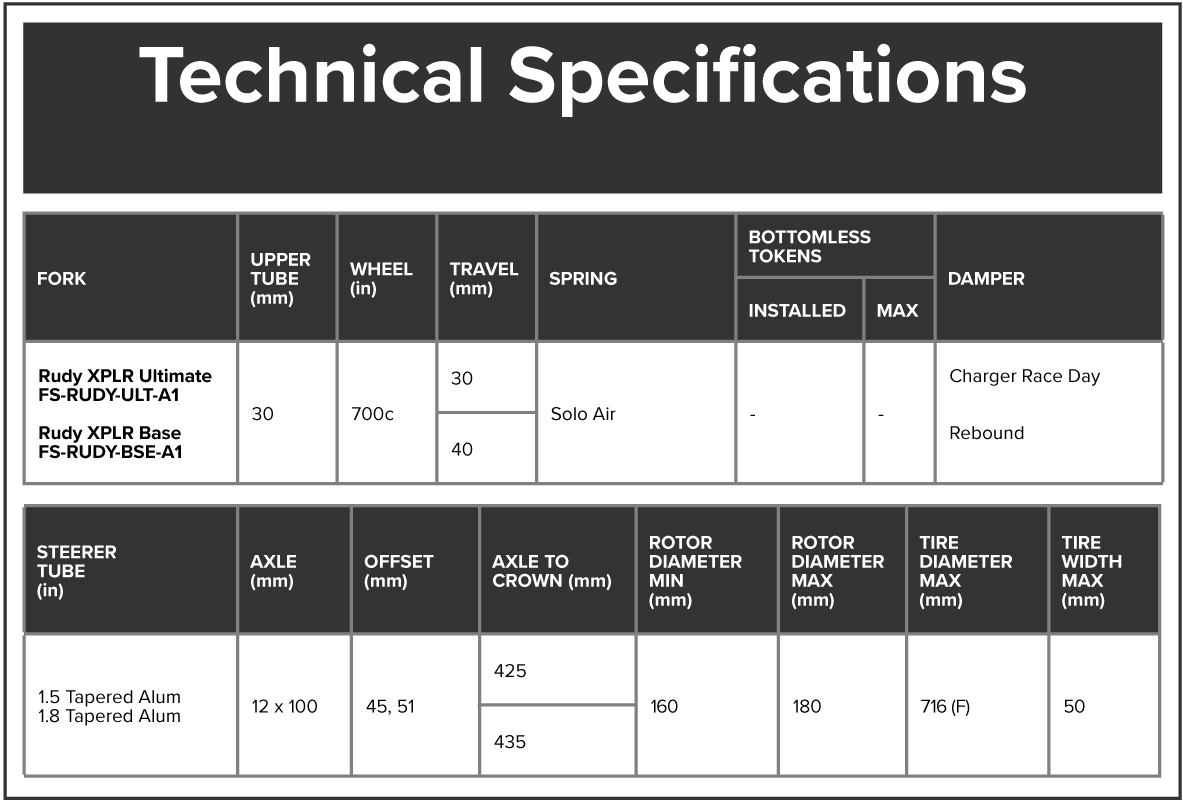

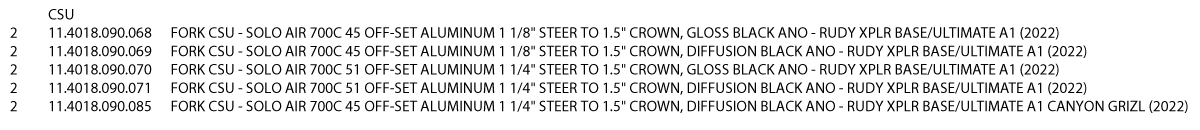

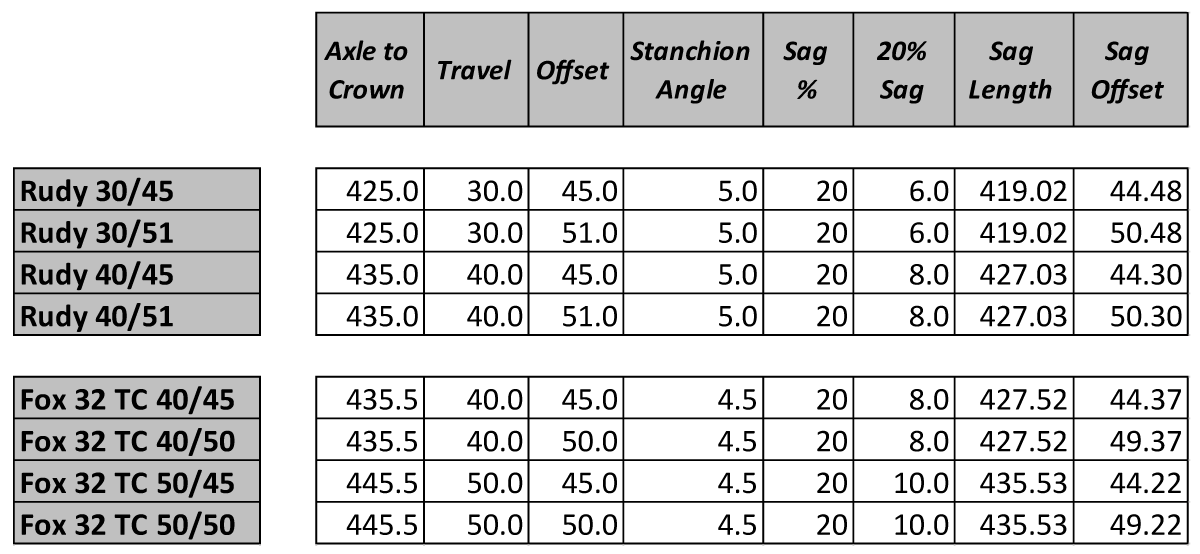

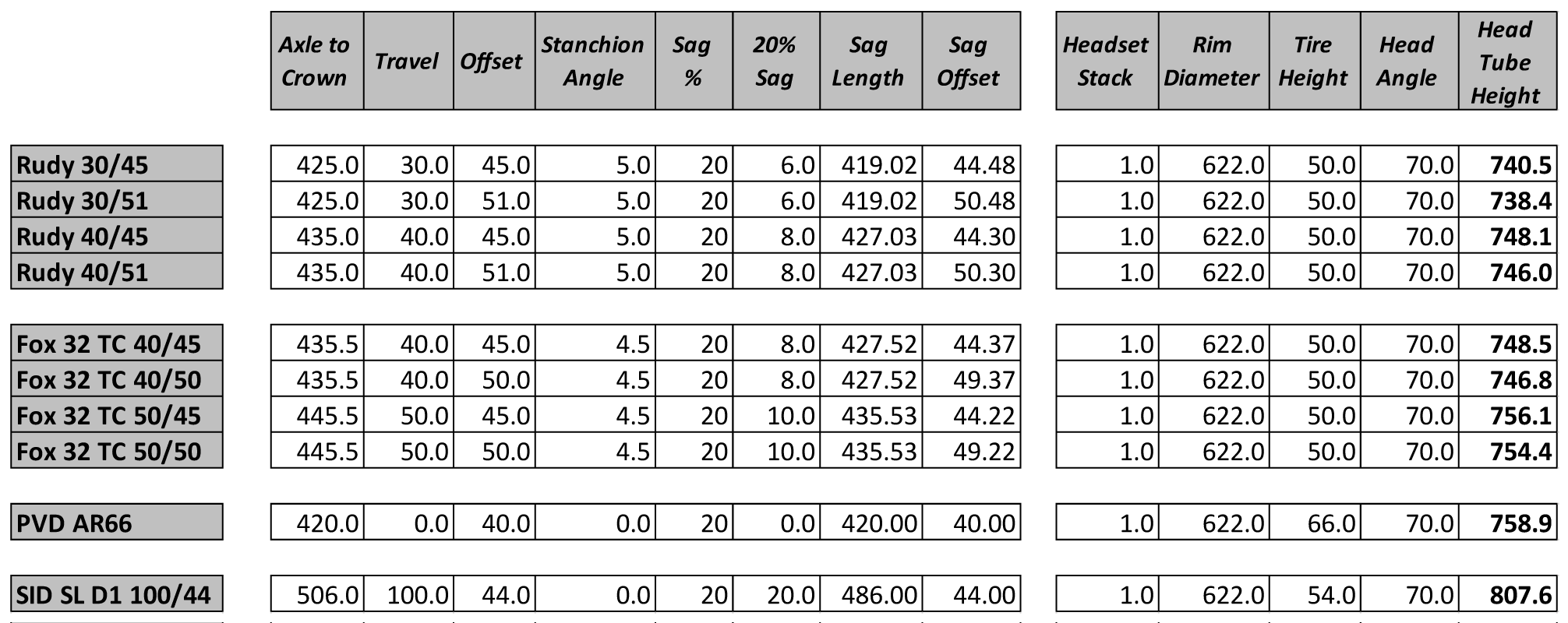

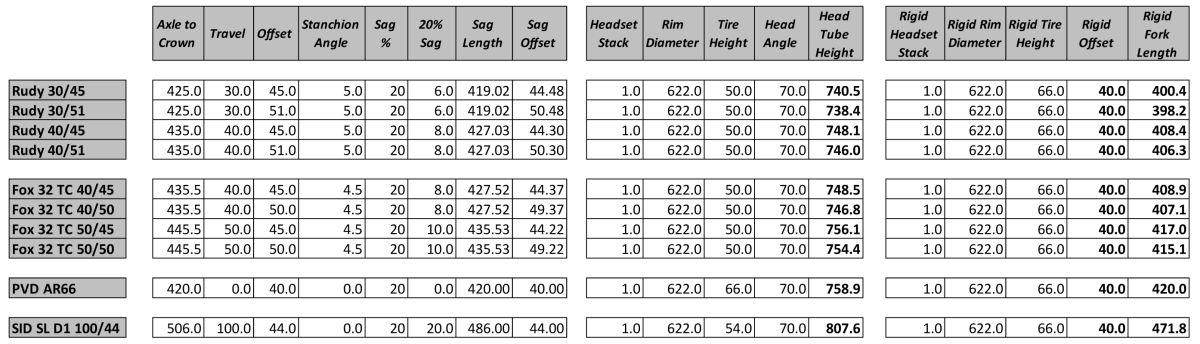

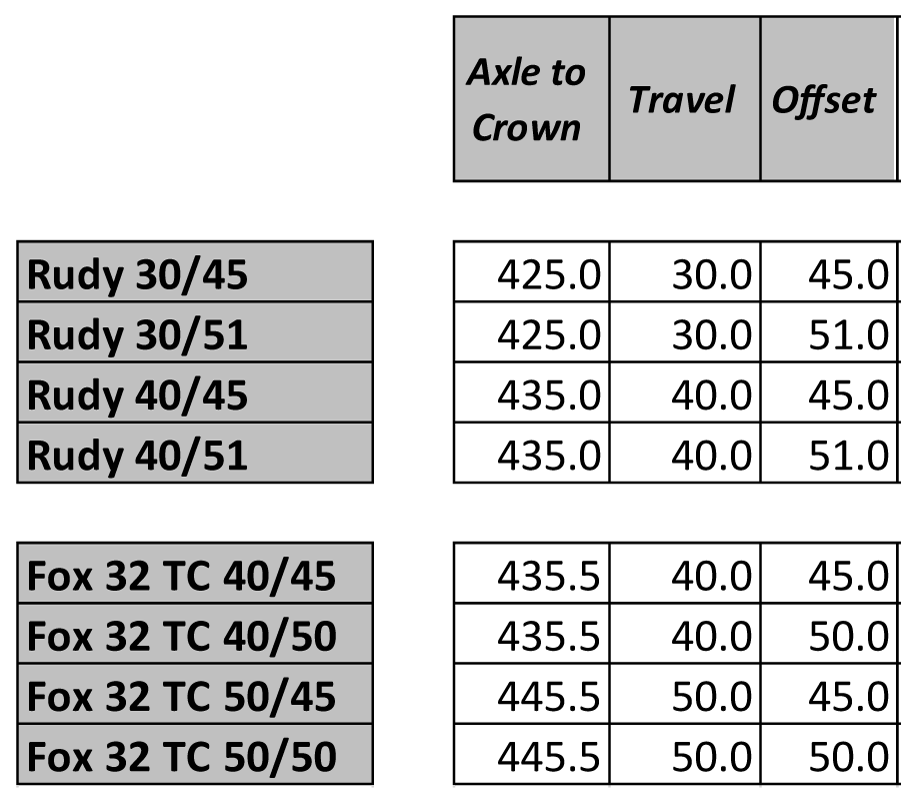

This idea opened a can of worms. Let’s take a look at the technical specifications of the RockShox Rudy and Fox TC forks.

So, four different geometric options. The Rudy produces its offset option by changing the CSU (crown). There are 2 geometrically different versions and a 1 1/4″ option.

Again, four geometric options for the Fox fork. Fox goes with longer travel options than RockShox. I believe that this is the correct direction comparing the two.

Cane Creek released their Invert fork in April 2024.

Cane Creek Invert SL, 40mm – 425mm atc/ 45mm offset/ 4° slider angle

Cane Creek Invert CS, 30mm – 435mm atc/ 45mm offset/ 4° slider angle

This is where most designers are going to start plugging numbers into BikeCad or modeling package to produce the bike…but it’s just not that simple.

Note: In my study, I found some irregularities and issues in the reported geometry of these forks. I will use reported values but I consider them suspect and in need of clarification by the manufacturers.

Unlike most suspension forks in the bicycle world, where the stanchions are aligned with the steerer, the stanchions on these forks are not. The SRAM fork has stanchions at a 5 degree angle and the Fox at a 4.5 degree angle (both approximate and unreported). This is a new kind of problem that shouldn’t be overlooked.

As the fork is sagged into the travel, the axle to crown measure changes, but the axle offset from the steerer changes also. These at the sine and cosine of the stanchion angle. This needs to be accounted for in the initial assumptions of the bike design. We can’t just subtract travel from the fork length and get values that reflect the true state of the system.

As stated, when the fork compresses into the travel, the offset is reducing. This as the now shorter fork has effectively made the head angle steeper. The instantaneous front wheel trail is reducing at a rate LESS than a typical suspension fork would. Depending on the designer’s goal, this could be a good or bad thing…regardless, it needs to be considered.

Now, we’re going to peel another onion layer that applies to both types of stanchion arrangements used in suspension forks.

As I mentioned at the start of this post, I wanted to see what geometry I would need to allow my custom rigid fork swap with as little disruption in the system as possible. The offsets of the fork are going to be different as I am looking for improved front wheel trail and flop values than can be attained with the production suspension forks. So, given a specific sag percentage, I want to know the length of the fork I’m making with the differing sag, that keeps the head at the same height. Then, all of the other bike geometry would be in the same state in that condition.

In addition to that, the rigid fork is going to use a very different tire size and that needs to be accounted for in these calculations. The all road suspension forks produced by SRAM and FOX allow for a maximum tire size of 622-50. My fork is designed for a 622-66. That’s quite a difference but it can be calculated easy enough.

Looking at this, any of these forks, even with the minimum of sag, is going to lower the head tube of my bike. The Fox 32 TC 50/45 fork comes close and would be the preferred option. Now I know.

This can go in reverse. Say I wanted to match a rigid fork to a bike that had been designed for one of these forks. I can modify the wheel, tire, and headset stack along with the offset and calculate a length that keeps the head tube height consistent with the earlier setup.

Also, were I in a jam and needed to produce something for a special case, I could adjust the height of the system by shimming the head tube as I have in the past.

To be clear, though. If I actually believed that this bike should have a suspension fork on the front, I would design for the better option: the RockShox SID SL D1 100/44. That with a remote would be a far superior option.

Before anyone get’s their panties all in a bunch, I did a lot of testing in the mid-teens to see if suspension and drop bars had a place in the all road platform as I use it. The 2016 PVD F-35 Lightning was used to test several different setups in many conditions. I found that, the drop bars were a terrible handicap and couldn’t keep up with the performance gains of the tire and fork in rough conditions. Flat bars can be configured in ways the make real aerodynamic improvements. More, even with flat bars, the fork did feel like a boat anchor in the real pedaling sections. Over the years, I found the right mix and this was the high volume front tire and rigid fork. This is why we test.