Talking with another framebuilder bro today. He seemed to not know about 110×12 hubs and axles for the front of narrow gauge bikes. I got a little bit mad. Everyone should know.

The market is currently flooded with fancy 100×12 wheels and exotic forks for road and gravel bikes. Cheap and expensive bikes are the same. Another boondoggle by the marketing idiots and roadies that don’t understand how bicycles work. Almost all of this happened long after mountain bikes had moved to 110mm front spacing. Going to 110×12 spacing was the OBVIOUS choice. The reasons are all the same.

But that’s not what happened. That change is going to happen in 2021 instead. Why? Because it took less effort to do less and make more money on secondary sales for upgrades that should have been stock years earlier.

Marketing shills and roadies; the enemy of bikes. They’re stupid but they know how to make money being stupid. If they do things wrong, they make more money.

Still, that the consumers haven’t realized that this is being done to them for the 5th time in 10 years, it’s really their fault. Consumers need to be interested in having better bikes, not just what’s marketed to them.

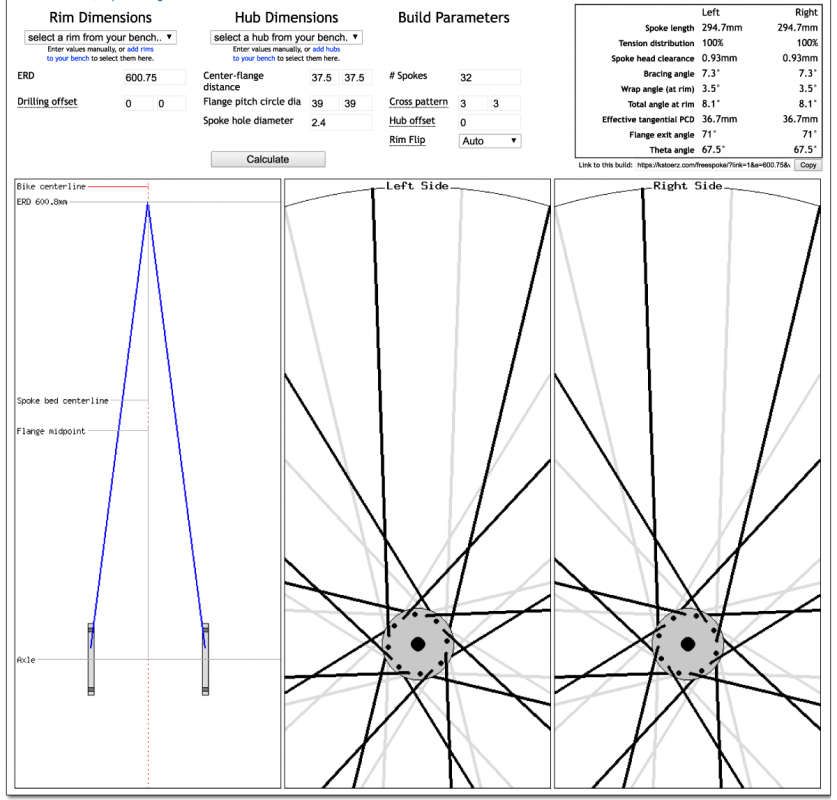

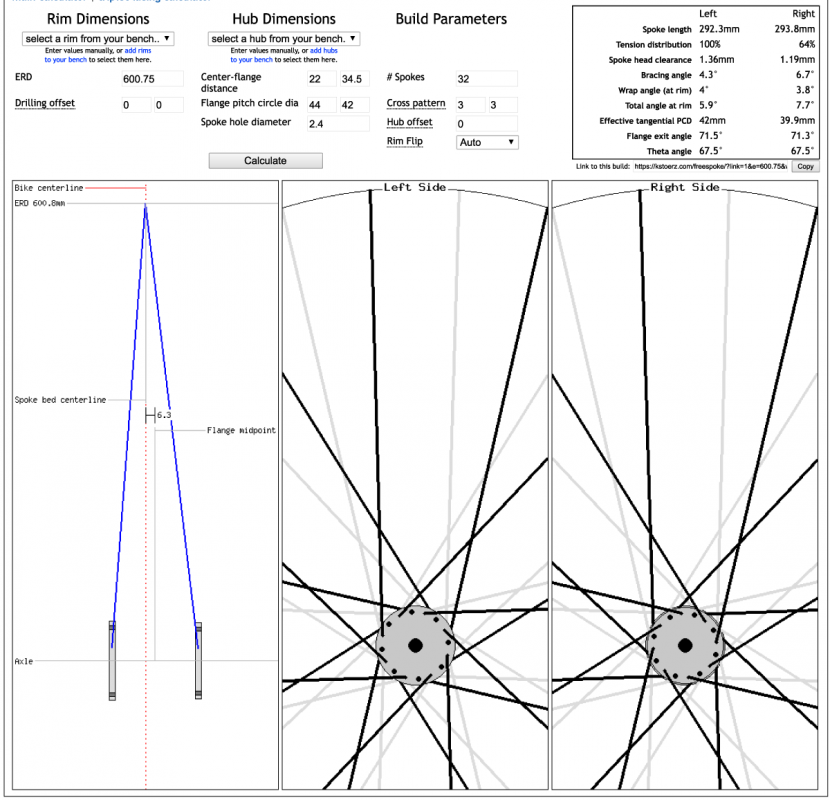

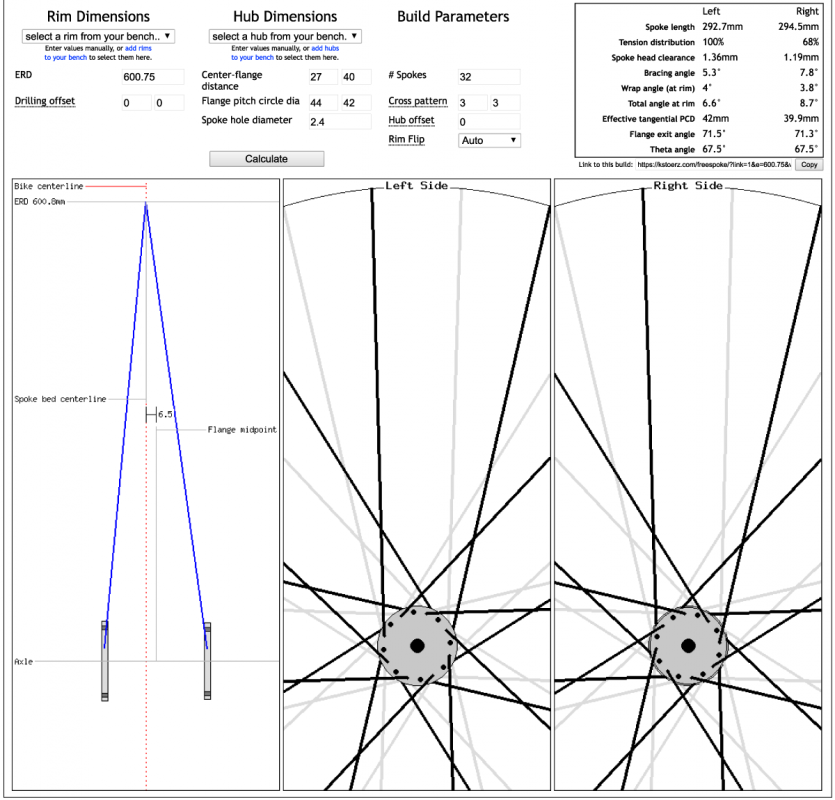

Here’s the math. Shown using FreeSpoke. FreeSpoke is great as it tells us far more than any other spoke calculator.

These wheels built with a WTB KOM i25 ISO622 rim, 32 hole, 3 cross, all dimensions from QBP wheel build data. The disc wheels were centerloc models.

110×12 hubs are produced using DT Swiss 12x100mm Thru Axle End Caps (HWGXXX00S7000S) and the 240S 110×15 hub. Obviously.

Look at the working angle that the spokes take.

DT Swiss 240S Front Hub: 32h, QR

H240AAQXR32SA1572S (HU0323 )

DT Swiss 240S Front Hub: 32h, 15mm Thru Axle, Center Lock Disc, Includes 12mm and QR end caps

H240ACIXR32SA2463S (HU0367)

DT Swiss 240s Front Hub: 32h, 15 x 110mm Thru Axle, Boost Spacing, Center Lock Disc

H240BCIXR32SA7657S (HU0401)

So, for spoke angles at the rim, we end up with:

DT240S 100×9 ND, 8.1°L and 8.1°R

DT240S 100×12 CL, 5.9°L and 7.7°R

DT240S 110×12 CL, 6.6°L and 8.7°R

Breaking out the lateral vector component:

DT240S 100×9 ND, 0.141L and 0.141R

DT240S 100×12 CL, 0.103L and 0.133R

DT240S 110×12 CL, 0.115L and 0.151R

Obviously, the non-disc wheels are by far the strongest and least aerodynamic wheels in the group.

The 100×12 wheel is 73% as strong pushing to the right and 93% pushing to the left compared to the 100×9 ND wheel.

The 110×12 wheel is 81% as strong pushing to the right and 7% stronger pushing to the left compared to the 100×9 ND wheel.

The 110×12 CL wheel is 12% stronger pushing to the right and 14% stronger pushing to the left compared to the 100×12 CL wheel.

Why is this important? With wheels, we want to use the lightest rims and get the most out of the spok thension that we can. Radial support for a wheel is easy but lateral support isn’t. By paying attention to the working angle of the spoke, we can significantly improve how the wheel performs in corners and when hitting rocks. We want wheels that can perform in extremes and not fail. Essentially, getting free strength from the geometry of the spokes is a simple part of this solution.

Of course, I’ve been using 110×12 hubs for a while. My Bird of Prey all-road bike uses the hub in a very fancy fork. Building a fork for anything else would just be silly.

I talked about offset rim drilling a few months ago.