Dang.

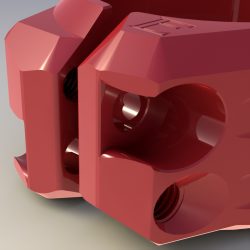

Back in early December of 2016, Drew (@engin) was all excited. He had been using his CNC milling machine since 2014 to make dropouts and he was looking to branch out. This was some seriously cool news. Drew is “all about the process” and this is some pretty real process. It’s proven to be an incredible investment and a quick look at his bikes will attest to that.

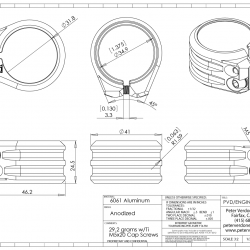

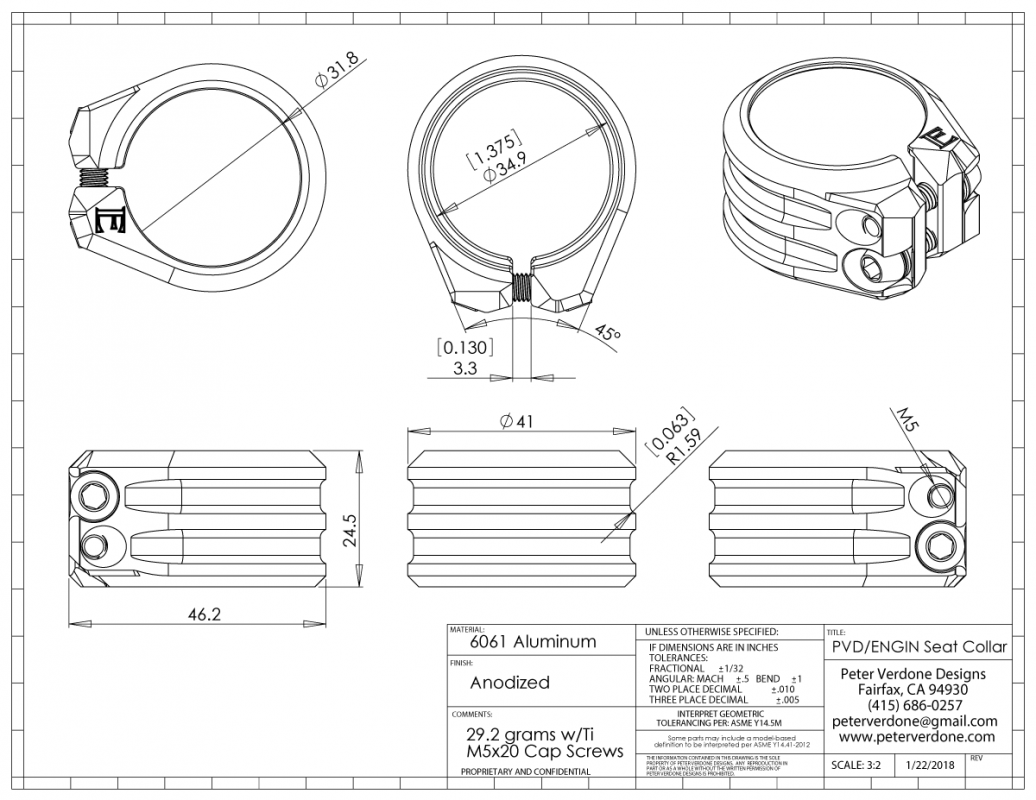

He gave me a call as we’ve worked on things together a bit, knowing my backround in machining and design. He said he was going to make a seat binder to learn the mill and showed me a drawing via message.

“No.”

“What?”

“You’re not making that.”

“Why not?”

“I’ll send you a file.”

A few hours later and some back and forth and there was a pretty nice design in front of him. A few more days and he had something really special.

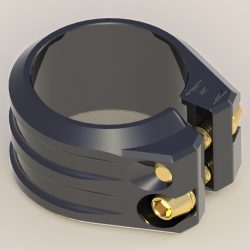

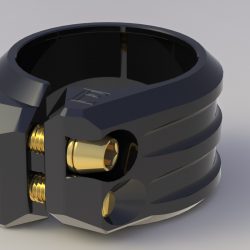

The goal here was to spread some of the clamping force over a greater area. Reducing the pressure created by each screw. To reduce the kind of hot spots that cause dropper posts to bind. It’s also one of the few areas on a bike that real attention can be drawn to design. It stands out. It’s better.

There are so many things going on with this design that it’s hard to list them. Take your time looking at it. You’ll be impressed.

This binder and a bunch of other frame parts were shown at the Philly Bike Expo:

https://cyclingtips.com/2017/11/philly-bike-expo-custom-bike-gallery-part-one/

2017 Philly Bike Expo: Engin Cycles Ti Mountain Hardtail – Jarrod Bunk

Things get lost in time. We all have different schedules and different priorities. It took until yesterday to get 15 unbranded examples of the part for my own use. It was worth the wait. I’m in awe of the great job Drew did and how well the design works.

Of course, comparison has to be made to the standard in seatpost binders, the Salsa Lip-Lock. It’s the old war horse and it looks good. It doesn’t fail. It’s what everything is measured against. Mine is 1.3 grams ligher (ha!) and has a whole lot more going on.

We did some testing on a few rough parts. It turned out that steel screws would fail before the binder would, or even stopped working. That’s dam good.