I recently wrote about obtaining a cool little “Lego” plate for setting up parts on my fiber laser. I talked a little about problems with the design and how it should have been produced. I made drawings to show my work. I had shared that information with Randy Lint but it seems to have fallen on completely deaf ears.

After a pair of conversations with Randy, I realized that the content of these discussions would serve as a great example of the problem with ‘maker’ culture and ways we can recognize when we are falling into them.

I’ve worked in machine shops and factories for most of my professional life. I like the work of building things. We design, cut, weld, paint and a magic thing is now in the world. But this has often been professional work. Real trade stuff and full of consequence and reward. There’s a seriousness that goes comes with all that. If I work on a racecar and that leads to a crash and a death, I’m fucked and going to hell.

The rise of the “maker movement”, while a fun hobby for many, has issues that need addressing. Some kid get’s an idea to get at it after an evening of YouTube and Google and he’s off to the races. He is going to do this and the guy on Instructables is going to tell him how. Fine. I love that. The problem is that there is a lot more that goes into much of “making” that a simple YouTube recipe doesn’t convey.

Guys like me will often try to help the newbies with filling in these gaps. Almost always, we are met with resistance and ignorance. Folks with the most to learn actively avoiding those with the most to teach. I personally deal with this all the time when talking about bicycles, skateboards, or motorcycles. Hell, I even got kicked off of a message board after calling a “titanium welder” out for not knowing that argon was heavier than air. Why did this matter? Because not knowing that can get somebody killed and that’s totally unacceptable if you are going to weld titanium (or anything really).

This discussion is utterly amazing and that’s why I chose to post it. The FB Messenger discussion is in two parts, the first during the initial purchase and the second the other day when I noticed he was scaling up his production and offering more sizes…with the errors still in place.

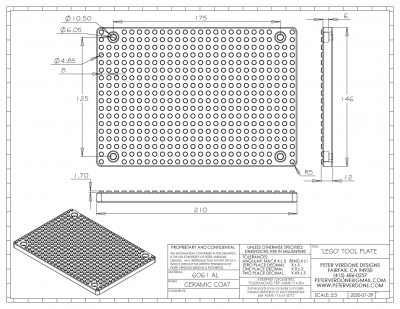

THIS FIXTURE PLATE MEASURES 8 1/4 X5 7/8 AND IS A DIRECT BOLT ON FIT FOR WISELY LASER PRECISION ADJUSTABLE TABLES. IT WILL WORK AS A STAND ALONE FIXTURE PLATE AS WELL AND MAY FIT OTHER BRANDS OF ADJUSTABLE TABLES. HOLE CENTERS MEASURE LEFT TO RIGHT – 6 29/32 AND TOP TO BOTTOM 4 15/16

Jul 24, 2020, 9:19 AM

Peter Verdone

RE: Lego plate,

Hey Randy. While I typically source Newport boards for this kind of stuff, your Lego plate project sounds fun. What is the cost and lead time on one of those?

Jul 24, 2020, 9:30 AM

Randy Lint Jr.

Cost is 99.95 due to the time it takes to make them. They are available at our website. www.lintarms.com under the fixturing category. Small batch runs of 8 plates at a time. I’m working to keep a steady supply in stock. Lead time on an order placed should only be a couple days plus shipping time. They will ship flat rate usps in the US only at the moment.

https://www.lintarms.com/

Jul 24, 2020, 9:57 AM

Peter Verdone

They are machined from aluminum correct?

Jul 24, 2020, 9:59 AM

Randy Lint Jr.

Yes, 6061 T6 American made Aluminum.

Jul 24, 2020, 9:59 AM

Peter Verdone

Also, 175mm x 125mm? You didn’t actually make them imperial, did you?

Jul 24, 2020, 10:00 AM

Peter Verdone

Most of the Chinese lasers are 25x25xM6 breadboard.

Jul 24, 2020, 10:01 AM

Peter Verdone

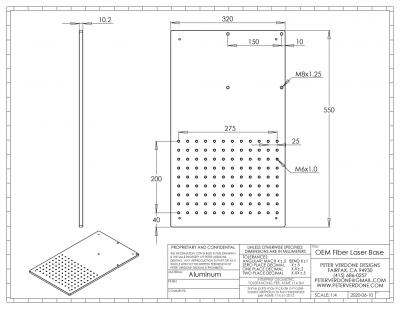

http://www.peterverdone.com/wp-content/uploads/2020/06/OEM-Fiber-Laser-Base.png

Jul 24, 2020, 10:02 AM

Randy Lint Jr.

My cnc is set up for imperial, so all the measurements I used for the machining process were converted. Fitment to the table is however spot on. I use M6 socket head bolts for mounting.

Jul 24, 2020, 10:03 AM

Peter Verdone

Your CNC works on fractional imperial. I’ve never heard of any machine working like that.

Jul 24, 2020, 10:04 AM

Peter Verdone

So, to be clear, you divided by 25.4 for the hole registration.

Jul 24, 2020, 10:04 AM

Randy Lint Jr.

Decimal. lol. I’ve got 20+ chat boxes open at the moment trying to keep up. my apologies.

Jul 24, 2020, 10:05 AM

Peter Verdone

I’m just particular about tooling. The original number was metric before you converted it, correct?

Jul 24, 2020, 10:11 AM

Peter Verdone

I’ve ordered one. You really should mention the material on your site and properly specify the holes. Carpenters use Imperial fractions. I’m not a carpenter.

Jul 24, 2020, 10:11 AM

Peter Verdone

I’m going to assume that it was designed with metric registration.

Jul 24, 2020, 10:13 AM

Randy Lint Jr.

The original dimensions for the lego posts were in metric, correct. I am not a math wiz so I used a conversion tool to convert to decimal equivalent. then to allow for the thickness of the cerakote, I had to adjust yet again. Then during the cam process while running simulations, discovered in order to use an 1/8th inch end mill, needed to adjust again. the end result worked out perfectly. it allowed me .0004 between each post for tool clearance, and after cerakote application provides a nice snug fit for the blocks.

Jul 24, 2020, 10:14 AM

Peter Verdone

I’m talking about the counter bores for bolting to the table. The laser table is a metric raster, 25x25xM6.

Jul 24, 2020, 10:16 AM

Peter Verdone

You shouldn’t really have to be doing any complex math. Did you cobble some sort of router out for this?

Jul 24, 2020, 10:16 AM

Peter Verdone

Imperial fractions?!?

Jul 24, 2020, 10:26 AM

Randy Lint Jr.

fractional dimensions were given for a quick measure with a scale. I plan to update more information. thank you for your business. we will get your plate right out to you.

Jul 24, 2020, 10:37 AM

Peter Verdone

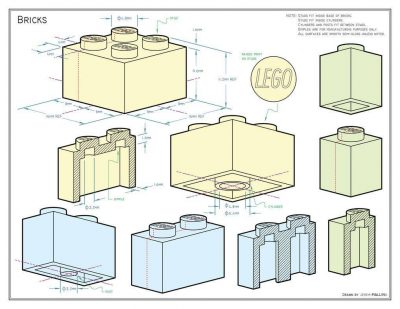

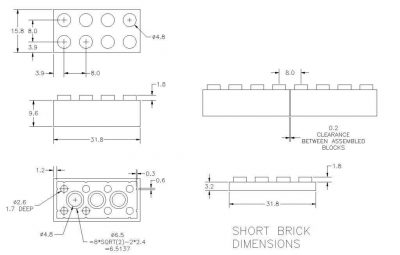

FYI, just measured a Lego. Nominally, (male) 8x8x4.85mm.

Jul 24, 2020, 11:07 AM

Randy Lint Jr.

0.1925 is the converted decimal dimension straight from Lego schematics. I run my posts at 0.189 and a total height of .070 I was not after copying their dimensions to the T. The goal is to make a fixture plate compatible with the use of LEGO blocks to fixture items for laser engraving. I’m working on cad models right now for add ons for my plates to hold specific items. Coins, tumblers, magazines etc. it’s an ongoing process and a learning process at that. Thanks again for your order and we hope you enjoy your plate and it makes quick setups a breeze for you like ours does for us.

Jul 24, 2020, 11:07 AM

Peter Verdone

Btw, where did you find the Lego schematic? Can you share that?

Jul 24, 2020, 11:14 AM

Randy Lint Jr.

Just a couple I’ve used for referencing.

Jul 24, 2020, 11:15 AM

Randy Lint Jr.

There are also many many CAD models available to import into your design to modify for your own projects.

Jul 24, 2020, 11:16 AM

Peter Verdone

Ah. Those aren’t actual Lego drawings. Those are ‘fan art’. Basically, you’re betting on them being right, and who are they?

Jul 24, 2020, 11:17 AM

Randy Lint Jr.

.189 is the measurement I was referencing earlier, not .1925 my posts are machined in the raw at .188

Jul 24, 2020, 11:19 AM

Randy Lint Jr.

That’s why I said these are a few I’ve used for reference. I pull several and compare dimensions, Legos original patent drawing doesn’t show dimensions. so for me personally, I just cross referenced as many drawings as I could and found what worked for my application. My goal wasn’t to copy Lego to the T, just make a compatible product to make quick and repeatable laser fixturing easier.

Jul 30, 2020, 10:25 AM

Peter Verdone

I got the fixture plate. Very nice finish.

I made a proper drawing for your reference.

http://www.peterverdone.com/wp-content/uploads/2020/07/2020-07-29-LEGO-Fixture-Plate.png

Jul 30, 2020, 10:31 AM

Randy Lint Jr.

Awesome. I’m glad it arrived on time. Great work on the drawings. They look very similar to my fusion360 drawings. Enjoy and thanks again!

Time passes. I notice that Randy is doing more production and of larger sizes. He still has the wrong units.

OUR LARGE FIXTURE PLATE. MEASURES 9.875 X 11.750 FITS ALL LASER BEDS WITH 2 INCH ON CENTER BOLT PATTERNS. MAY BE USED FOR OTHER APPLICATIONS BUT WILL REQUIRE YOUR OWN SOLUTION FOR MOUNTING (DRILLING AND TAPPING NEW HOLES OR SECURING WITH LESS THAN THE SUPPLIED BOLTS). THE BOLT PATTERN IS 9 13/16 (9.8125) LEFT TO RIGHT AND 7 7/8 (7.875) TOP TO BOTTOM. PLATE IS CNC MACHINED FROM 100% AMERICAN 6061 T6 ALUMINUM AND COMES WITH FOUR (4) M6-1 FASTENERS TO SECURE TO YOUR LASER BEDS FACTORY FIXTURE PLATE WITH 2 INCH ON CENTER PATTERN.

Oct 10, 2020, 5:03 PM

Peter Verdone

So strange that you didn’t fix your design for the current plates. “THE BOLT PATTERN IS 9 13/16 LEFT TO RIGHT AND 7 7/8 TOP TO BOTTOM. ”

So, 249.2375 mm x 200.025 mm instead of 250 mm x 200 mm. I tried to help you when I shared the print. This kind of thing matters.

Oct 10, 2020, 5:10 PM

Randy Lint Jr.

Agreed. But for the purpose of someone checking fitment with a standard scale, it gets the job done. 2×2 bolt pattern should be self-explanatory. I went a step further with the quick reference measurements. I don’t use the metric system in my shop. Thank you though for the feedback.

Oct 10, 2020, 5:11 PM

Peter Verdone

None of this makes any sense.

Oct 10, 2020, 5:11 PM

Peter Verdone

So you own a calculator? It’s just x/25.4. Pretty simple stuff.

Oct 10, 2020, 5:22 PM

Randy Lint Jr.

None of what makes sense? The holes are approximately 9 13/16 apart from left to right. And 7 7/8 apart from top to bottom. Anyone using a standard inch scale can quickly reference if the plate will fit their table. It’s not an aerospace application. Tolerances are beyond loose on the Chinese tables to begin with. Lol. I also have the cad model I designed with exact dimensions. But considering most people use a tape measure or a ruler, decimals would be pointless for quick reference. Hence why I stated the 2-inch bolt pattern is what it fits. I really do not see the point in critiquing here? I run my shop in my spare time for the fun of it. If someone passes on buying one of my plates simply because I was off by an insignificant amount in my description, so be it. But the hundreds of customers who have bought them and continue to buy them, don’t seem to mind. Thanks though for insulting me with the “so you own a calculator and its pretty simple stuff” comment. You find joy in nitpicking people in your spare time over things?

Oct 10, 2020, 5:23 PM

Peter Verdone

The holes are exactly 250 mm x 200 mm. That’s the difference.

Oct 10, 2020, 5:24 PM

Peter Verdone

9.84251969″ x 7.87401575″

Oct 10, 2020, 5:31 PM

Randy Lint Jr.

Cool. And I agree that’s probably the exact hole spacing. But my stated quick reference measurements using a Starrett scale I have laying right beside my laser is what I used to give someone else using a standard scale the numbers they need to check fitment before they make their purchase. Not an issue. Most who have inquired ask me for standard inch measurements on a 1/16th scale. Some ask on a 32nd scale. I provided mine from the 16th side of my scale. Pretty simple really. Anyone wanting precise measurements simply had to do the conversion on the stated 2 inch on center bolt pattern. Again, no one has ever complained or requested measurements out 8 places. Lol. It’s going on a Chinese made laser bed, not the moon landing. Have a great day.

Oct 10, 2020, 5:33 PM

Peter Verdone

It’s a metric pattern. It’s just a 25mm x 25mm raster. That shouldn’t be an issue.

Oct 10, 2020, 5:34 PM

Peter Verdone

My plate fit poorly. It worked. But only just fit. It’s a shame.

Oct 10, 2020, 5:35 PM

Peter Verdone

I figure if you are buying a few thousand dollars’ worth of aluminum, you could buy a calculator. $3 at Staples.

Oct 10, 2020, 5:35 PM

Peter Verdone

I even supplied a corrected print.

Oct 10, 2020, 5:47 PM

Randy Lint Jr.

If your plate fit poorly then I’d say your table is off. I’ve yet to have a customer complain of fitment issues, Including the plate I have mounted on my table. If your table is correct, then I’d say my exact measurements from my design are in fact off. Quite an easy fix. However, the fact that no one is sounding the alarms and criticizing fitment, I believe the tolerances for this application are acceptable. Again, it’s not aerospace equipment we’re dealing with. If it were to be an actual problem, of course I would make the necessary adjustments. And again, that’s enough with the insults. Feel free to not contact me again if that’s all you care to do is trash talk.

Oct 10, 2020, 7:12 PM

Peter Verdone

This is so insane. How did I insult you? I’m trying to help you.

My part fit poorly because you aren’t cutting to a metric spec. The board is not wrong, your part is, as you’ve testified here at length.

Usually, people are grateful to learn their errors. This is why this is so nuts.

Oct 10, 2020, 7:26 PM

Randy Lint Jr.

That’s my point. I did not design them to exact metric specs. Never even tried to from the get go. I simply made a product that with the exception of you, has served hundreds of people’s needs just fine as is. I’m not contesting that my part is out of metric specs. Not at all. It’s exactly to spec as it was designed and you are insulting me with comments like “do you own a calculator” or “they are only 3 dollars at the store” and “pretty simple really”. I’m not an idiot man. I taught myself CNC from scratch with zero schooling. Pretty good accomplishment I’d like to think for a dumb dumb steelworker like me without a college degree. Never claimed to be a master. Simply a guy who enjoys making things in his spare time helping others to enjoy their work as well. You may not have intended to offend, but that doesn’t mean you didn’t. I get your point. I do. And who said I didn’t appreciate the input? You made that assumption simply because I said I was offended by your other comments. If I were running a multimillion dollar corporation or even a profitable job shop, I could see being stringent with my processes. But it’s literally a side hobby in my garage. The products I make with the equipment I have to work with serve my customers’ needs just fine. Even that rare case where one “didn’t fit well, but it fit”. You seem like a pretty good person. Very intelligent. Very generous with handing out knowledge. I appreciate that. Just don’t be so abrasive with the delivery. Have a good rest of your weekend.

I’m sharing this exchange because I think that it illustrates several issues dealing with makers and novice engineers.

-

- Feedback or input is not an insult. If someone takes the time to give you feedback on a design, listen. I didn’t have to try to teach him something. I did it because that’s how we all learned, because someone gave us their time.

- When someone who knows more than you tells you something, don’t defend first, listen. Think about it. I didn’t need Randy to explain why he was doing it wrong. I knew that. I needed him to listen.

- The way you did it is probably wrong. Do you want to learn the right way? I get things wrong all the time. I would love it if someone told me that that knew why. That would save me so much energy and time.

- Don’t believe what you read on the Internet. Randy shows some drawings that some kid or graphic artist produced. Who did the drawings? Are the drawings correct? Did he just accept them as gospel. If I had a penny for every wrong thing I’ve read on the internet I’d be the richest man in the world.

- You’re a late bloomer, a total noob, “just getting started”, #needsagoldstar, Great! Nobody cares. You need to put the hard work of learning in regardless of where you are in all this. Pony up. Randy thinks he deserves a prize for getting this far. Nobody cares.

- Imperial dimensions are often used in the US. Those are what your granddaddy used. Great! Nobody cares. Use the correct dimensions and nomenclature. Reference dimensions correctly. Use tolerances. This shit is actually really important.

- Fractional measures are used by carpenters and children. Which is Randy?

- Using a Starrett scale doesn’t add any legitimacy to measuring fractional inches instead of millimeters. Don’t try to use branding or ‘premium’ to make up for using a tool wrong.

- Don’t be a fake. You can fool mom to get a cookie but you’re not going to fool an expert. You end up looking like a real idiot when you fake. If you cop to not knowing, you can start learning. That’s what smart people do. Randy reasoned that his mistakes are there because; “My cnc is set up for imperial”. I’ve worked as a CNC machinist, as designer, and engineer. 1.000 inches is 25.4 millimeters, exactly. He’s trying to snow me and that makes him look stupid.

- Work desperately hard to make your shit perfect. You’ll still make mistakes but far fewer than if you don’t try. Randy isn’t focused on improvement. He’s focused on making. That’s a mistake.

- Every production run is an opportunity to move forward. I like to say, “never waste a prototype”. Advancement, always. Randy has produced several runs of parts containing the same mistake that I pointed out months ago. That is truly stupid.

- Don’t blame others for your mistake. Here, Randy blames the Chinese plate for the poor fit up, even as he has explained at length that he cut them to the wrong size. Take the blame. Fix that shit.

- Details matter. Randy said “Great work on the drawings. They look very similar to my fusion360 drawings.” This is a can of worms:

- Your drawing, that you don’t show may “look” similar but it’s not. Mine is correct. See that.

- You’re using 3D CAD and referencing imperial fractions for CNC work? That’s insane.

- You can work CAD in metric and export to imperial units. This takes a single button press. How do you not know this?

- Quality work is quality work. It doesn’t matter if it’s going into space or on a stovetop. Do good work. If you think doing bad work is ok, just stop.

- In the time it took Randy to make even one of his replies, he could have fixed the problem. He didn’t. He argued. That’s a terrible use of his time. If I know a model or drawing is wrong, it’s my only priority on earth to fix it ASAP.